epdm sealing strip factory

Oct . 19, 2024 07:55 Back to list

epdm sealing strip factory

The Importance of EPDM Sealing Strip Factories in Modern Manufacturing

In the world of manufacturing and construction, the integrity of structures largely relies on the effectiveness of sealing materials. Among the various sealing solutions available, EPDM (Ethylene Propylene Diene Monomer) sealing strips have emerged as a crucial component in providing reliable sealing capabilities. EPDM sealing strip factories play an essential role in producing these vital components, catering to industries that prioritize durability, weather resistance, and flexibility.

EPDM is a type of synthetic rubber known for its excellent resistance to heat, oxidation, and ozone, making it ideal for outdoor use and harsh environments. These properties ensure that EPDM sealing strips can endure extreme weather conditions, from scorching sunlight to freezing temperatures, without deteriorating. The versatility of EPDM also allows it to maintain its flexibility over time, making it an excellent choice for applications where the sealing material needs to conform to varying shapes and surfaces.

The Importance of EPDM Sealing Strip Factories in Modern Manufacturing

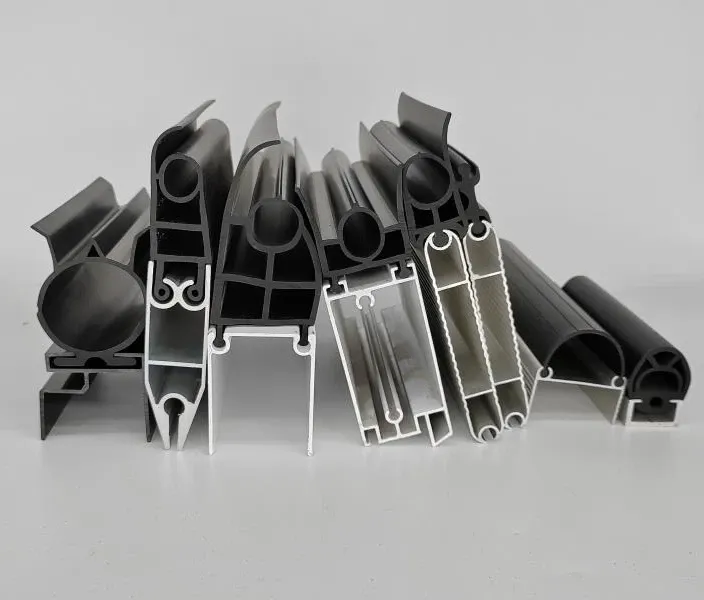

A significant aspect of EPDM sealing strip factories is their ability to provide customized solutions. Many industries, including automotive, construction, and electronics, have unique sealing requirements that standard products may not fulfill. EPDM sealing strip factories work closely with clients to develop tailored sealing solutions that fit their specific needs. This includes producing strips of various sizes, shapes, and thicknesses, as well as providing different surface finishes and colors. The ability to customize seals is particularly important for industries where precision and reliability are paramount.

epdm sealing strip factory

Another important factor that strengthens the role of EPDM sealing strip factories is their contribution to sustainability. As businesses around the globe strive to reduce their environmental footprint, the demand for eco-friendly materials has surged. EPDM can be recycled, and many factories are adopting sustainable practices in their manufacturing processes. The use of environmentally friendly production methods not only helps in reducing waste but also appeals to consumers who are increasingly conscious of the environmental impact of their purchases.

Additionally, EPDM sealing strips are extensively used in energy-efficient applications. For instance, in the automotive sector, they help in reducing noise, vibration, and harshness (NVH), while also improving the overall thermal efficiency of vehicles. In construction, EPDM strips are crucial for providing airtight seals in windows and doors, thereby contributing to energy conservation in buildings. By ensuring that structures remain insulated, EPDM sealing strips play a significant role in lowering energy consumption and reducing utility costs.

The global demand for EPDM sealing strips continues to rise, driven by the ongoing expansion of various industries. EPDM sealing strip factories are poised to grow in significance, as they not only meet the current market needs but also pave the way for innovative sealing solutions in the future. As technology advances, we can anticipate the development of even more efficient manufacturing techniques and products, further enhancing the performance of EPDM sealing strips.

In conclusion, EPDM sealing strip factories are indispensable players in the manufacturing landscape. Their commitment to producing high-quality, durable, and eco-friendly sealing solutions is essential for numerous industries. As we continue to face challenges related to climate change and resource conservation, the role of these factories will only become more critical. By providing reliable sealing solutions that stand the test of time, EPDM sealing strip factories are contributing significantly to the safety, efficiency, and sustainability of modern manufacturing and construction practices.

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025