glass door rubber seal strip factory

Dec . 05, 2024 15:10 Back to list

glass door rubber seal strip factory

Understanding Glass Door Rubber Seal Strip Factories

When it comes to ensuring that a space is energy-efficient, secure, and comfortable, the role of rubber seal strips in glass doors cannot be understated. Glass door rubber seal strip factories play a crucial role in manufacturing these essential components that contribute to the longevity and functionality of glass doors in both residential and commercial settings. This article delves into the significance, production processes, and the benefits of rubber seal strips, spotlighting why experts emphasize quality and innovation in this sector.

The Importance of Rubber Seal Strips

Rubber seal strips are designed to fill gaps between glass doors and their frames. These strips serve multiple purposes, including preventing air leaks, reducing noise pollution, and enhancing the insulation properties of the door. By creating a tight seal, they help maintain indoor temperatures, saving energy and reducing heating and cooling costs. Furthermore, rubber seals protect against water intrusion, which can lead to mold growth and structural damage over time.

Overview of Manufacturing Processes

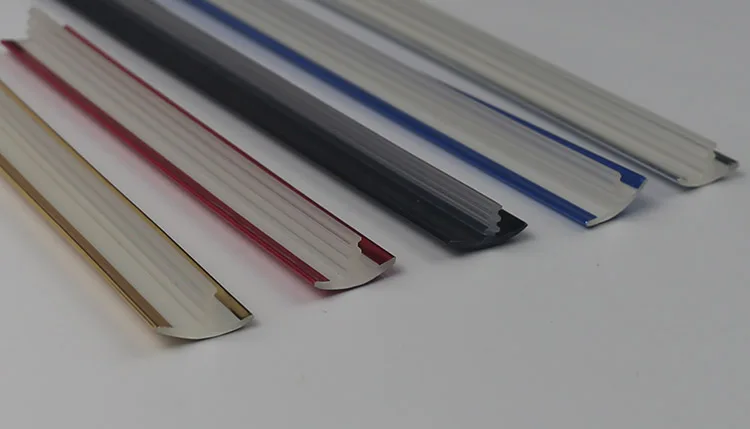

The production of rubber seal strips involves several critical stages, each tailored to meet precise specifications for different types of glass doors. High-quality materials, typically EPDM (ethylene propylene diene monomer) or silicone, are selected based on their durability, temperature resistance, and flexibility. The manufacturing process includes

1. Material Preparation Raw rubber compounds are mixed with additives to enhance performance characteristics such as UV resistance and elasticity. This step is crucial as the quality of the raw materials directly impacts the final product.

2. Molding and Extrusion The prepared rubber is then either molded or extruded into specific shapes that suit various door designs. Extrusion is the more common method for rubber seals as it allows continuous production of long strips that can be cut to length according to customer requirements.

3. Curing and Finishing After molding or extrusion, the rubber undergoes a curing process, wherein it is heated to achieve its final shape and enhanced durability. Post-curing, the seal strips are meticulously inspected for quality assurance before they are cut, packaged, and prepared for shipping.

glass door rubber seal strip factory

Challenges in the Industry

Operating a rubber seal strip factory comes with its set of challenges. The industry faces pressure to produce high-quality products while maintaining competitive pricing in a global market. Additionally, increasing environmental regulations push manufacturers to adopt more sustainable practices. Finding a balance between cost, quality, and environmental responsibility is crucial for factories aiming to remain relevant.

Innovations and Trends

In recent years, advancements in material science and production technology have led to the development of innovative rubber seal strips. These include noise-reducing seals, energy-efficient designs, and even smart seals integrated with sensors that alert users to gaps or malfunctions. Such innovations not only enhance the functionality of glass doors but also cater to the evolving demands of consumers who prioritize sustainability and smart technologies.

Benefits of High-Quality Rubber Seal Strips

The benefits of investing in high-quality rubber seal strips extend well beyond immediate performance. Quality seals contribute to the overall longevity of glass doors, reducing the need for replacements and repairs which can be costly. Furthermore, they add a layer of aesthetic appeal, creating a seamless look that enhances the overall design of the space. Consumers are increasingly aware of the long-term costs associated with poor-quality seals, which is driving demand for superior products.

Conclusion

In summary, glass door rubber seal strip factories play a vital role in the construction and maintenance of glass doors. By ensuring their products meet high-quality standards and innovating to keep pace with industry demands, these factories contribute significantly to energy efficiency, comfort, and aesthetic appeal in both residential and commercial installations. As the market evolves, continuous improvements in manufacturing processes and material technologies will remain essential to address the challenges and drive the industry forward.

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025