High-Quality OEM Sponge Rubber Seals for Enhanced Durability and Performance in Various Applications

Aug . 01, 2024 05:26 Back to list

High-Quality OEM Sponge Rubber Seals for Enhanced Durability and Performance in Various Applications

Understanding OEM Sponge Rubber Seals Importance and Applications

In the realm of manufacturing and engineering, the use of specialized components is crucial for maintaining quality and efficiency. One such component that has gained significant attention is the OEM sponge rubber seal. This product, while often overlooked, plays a vital role in a variety of applications across different industries.

OEM, or Original Equipment Manufacturer, refers to products made by a company that are used in the manufacturing of another company's product. Sponge rubber seals are soft, compressible components made from rubber or elastomeric materials. They are specifically designed to fit snugly into joints or around components, serving as a barrier to protect against environmental factors such as dust, moisture, and temperature fluctuations.

Understanding OEM Sponge Rubber Seals Importance and Applications

In the automotive industry, for instance, sponge rubber seals are used extensively in the assembly of vehicles. They are found in engine components, doors, windows, and trunk lids, providing insulation against noise, vibration, and harsh weather conditions. This enhances the overall comfort and experience of the passengers while also contributing to fuel efficiency by preventing air leaks.

oem sponge rubber seal

Aerospace applications also benefit significantly from OEM sponge rubber seals. In this industry, where safety and reliability are paramount, these seals are used in components that are exposed to high altitudes, extreme temperatures, and varying pressures. The seals ensure that critical systems, such as fuel lines and cabin pressurization systems, function correctly, thereby enhancing the safety of aircraft operations.

In the electronics sector, sponge rubber seals serve to protect sensitive components from dust and moisture, which can lead to significant operational failures. Devices such as smartphones, laptops, and various consumer electronics often include these seals to enhance durability and enhance user satisfaction. They help maintain the integrity of electronic products, ensuring longevity and performance.

The manufacturing process of OEM sponge rubber seals involves several steps, including material selection, design, and testing. High-quality materials such as silicone, neoprene, and EPDM are commonly used, depending on the application's specific requirements. The design process often utilizes computer-aided design (CAD) software to create precise dimensions that will ensure a perfect fit and optimal functionality.

Moreover, rigorous testing is an integral part of developing OEM sponge rubber seals. These tests assess factors such as compression set, tensile strength, and resistance to various environmental conditions. Ensuring that seals can withstand wear and tear over time is crucial for maintaining the integrity of the products they are used in.

In conclusion, OEM sponge rubber seals are indispensable components across a variety of industries. Their versatility, durability, and effectiveness in sealing applications make them a focal point in the design and manufacturing processes. As technology and materials advance, the efficacy and application of these seals are likely to expand, further solidifying their importance in modern engineering and manufacturing. Whether in automotive, aerospace, electronics, or construction, the impact of high-quality sponge rubber seals is profound, ensuring that products remain safe, reliable, and efficient.

-

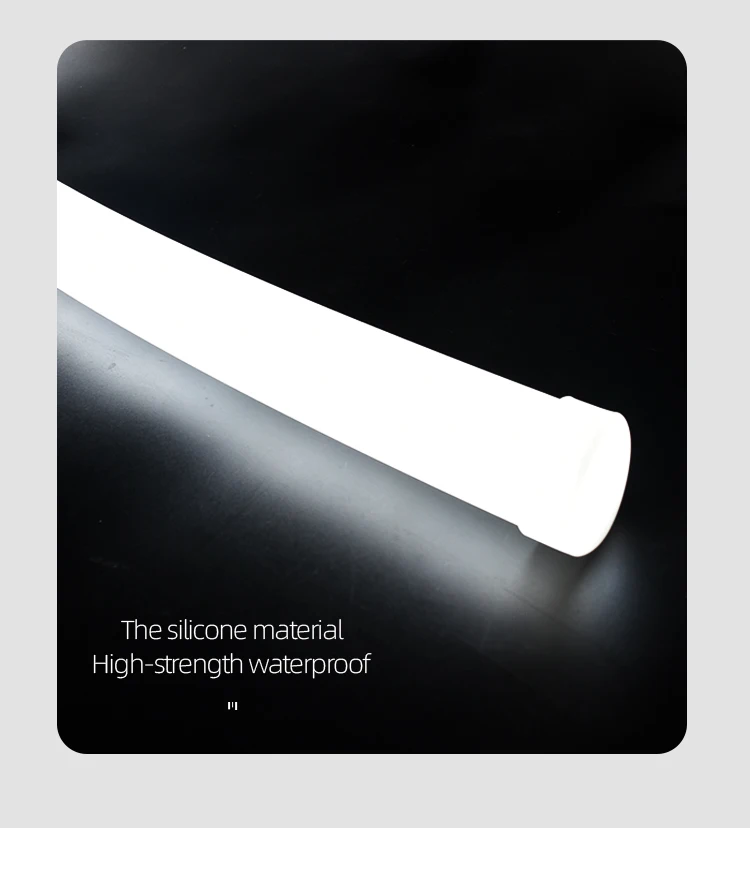

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025