high polymer material sign factories

Nov . 19, 2024 17:12 Back to list

high polymer material sign factories

The Significance of High Polymer Material in Modern Factories

High polymer materials have become indispensable in the manufacturing sector, particularly in factories where efficiency, durability, and cost-effectiveness are paramount. These materials, characterized by long molecular chains and unique physical properties, are reshaping the landscape of product design and production processes. This article explores the key benefits and applications of high polymer materials in factories today.

Understanding High Polymer Materials

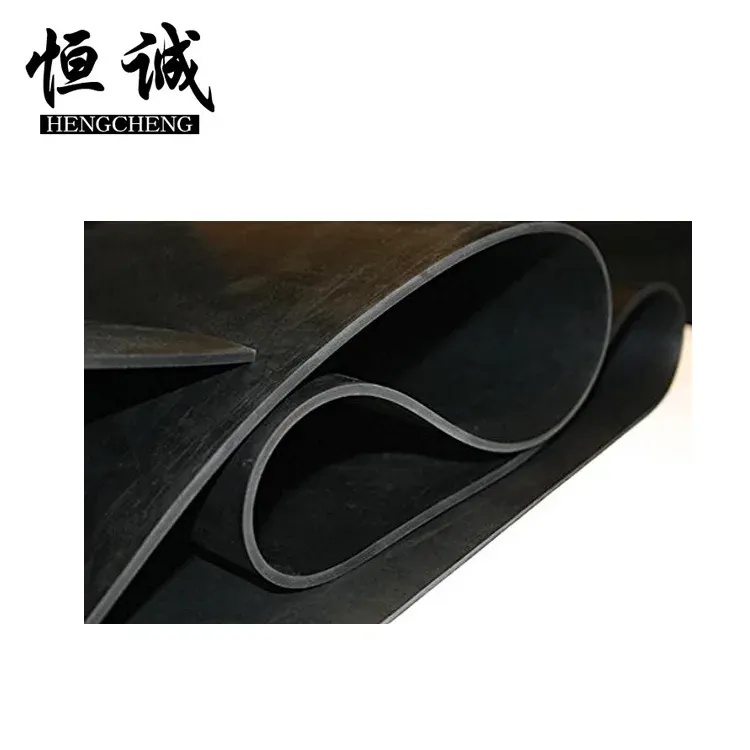

High polymer materials, often referred to as polymers, include a wide range of substances such as plastics, elastomers, and fibers. They are created through the polymerization process, where small molecular units, or monomers, are chemically bonded together to form larger, complex structures. Polymers can be classified into thermoplastics, thermosets, and elastomers, each possessing distinct features that make them suitable for different applications.

Benefits of High Polymer Materials

1. Lightweight and Strong One of the most significant advantages of high polymer materials is their exceptional strength-to-weight ratio. This property makes them ideal for industries that require lightweight components without compromising durability. For instance, in the automotive and aerospace sectors, high polymers are used extensively to reduce overall vehicle weight, leading to improved fuel efficiency and performance.

2. Corrosion Resistance Unlike metals that can corrode over time, high polymer materials are resistant to many chemicals and environmental factors. This characteristic makes them particularly useful in industries like oil and gas, where equipment is frequently exposed to harsh conditions. Therefore, utilizing high polymer components can extend the lifespan of machinery and reduce maintenance costs.

3. Versatility in Design High polymer materials offer unparalleled design flexibility. They can be easily molded into complex shapes and structures, meeting the specific needs of various applications. This versatility not only broadens the scope of product development but also allows manufacturers to innovate and introduce new products rapidly.

4. Cost-Effectiveness Manufacturing with high polymer materials can be more economical compared to traditional materials such as metals or ceramics. The production processes for polymers are often more streamlined and require less energy, leading to lower overhead costs. In many cases, polymer components can be produced at scale, further reducing costs and enhancing profitability.

high polymer material sign factories

Applications in Modern Factories

High polymer materials are employed in a myriad of applications across different industries.

- Electronics In the electronics industry, polymers serve as insulators and housings for components due to their excellent electrical properties. They are vital in producing circuit boards, connectors, and various devices, ensuring protection and performance.

- Packaging The packaging industry relies heavily on high polymer materials, especially plastics, for their ability to seal in freshness and protect products during transportation. The lightweight nature of polymers also contributes to lower shipping costs.

- Automotive In automotive manufacturing, high polymers are utilized in both exterior and interior components. From bumpers to dashboard materials, polymers help reduce weight and enhance fuel efficiency, meeting the industry's push for greener solutions.

- Medical Devices The medical field has seen a surge in the use of high polymer materials for devices and instruments. Their biocompatibility and ease of sterilization make them ideal for applications ranging from surgical tools to implants.

Future Outlook

As we move into an era emphasizing sustainability and innovation, the role of high polymer materials in factories is set to grow. Advances in material science are leading to the development of bio-based and biodegradable polymers, which align with the global push towards environmental sustainability.

In conclusion, high polymer materials represent a cornerstone of modern manufacturing, providing myriad benefits from lightweight strength to cost savings. Their versatility and adaptability make them crucial in enhancing efficiency and driving innovation across various industries. As technology continues to advance, we can expect high polymer materials to play an even more significant role in shaping the factories of the future.

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025