high quality seal strip turbine

Nov . 14, 2024 21:35 Back to list

high quality seal strip turbine

The Importance of High-Quality Seal Strips in Turbine Applications

In the realm of engineering and manufacturing, turbines play a crucial role in energy generation, from wind to hydro and thermal power. As the demand for efficient and reliable energy sources continues to grow, the components that form these crucial machines must be meticulously designed and manufactured. Among these components, high-quality seal strips are essential, serving both functional and protective roles within turbine systems.

What Are Seal Strips?

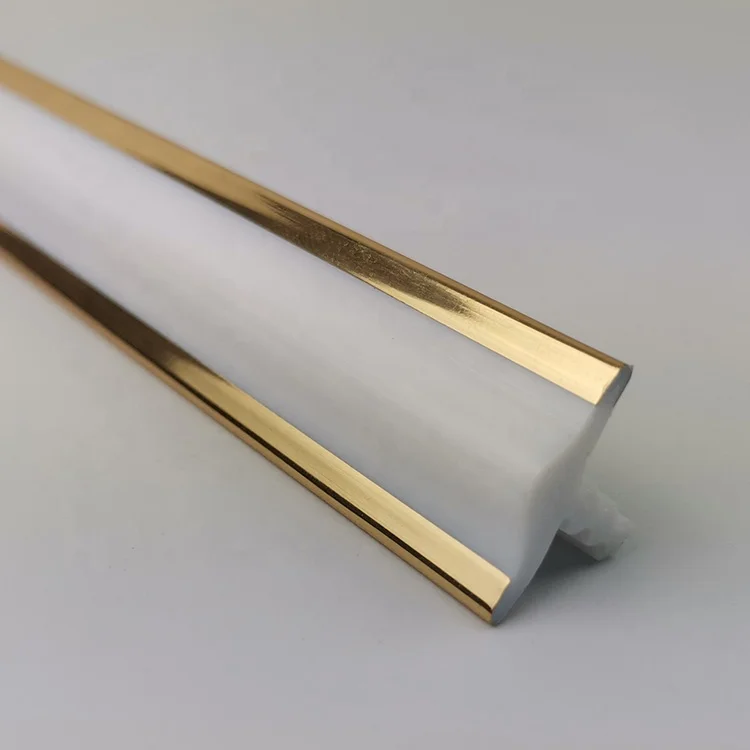

Seal strips are elastomeric materials designed to prevent the leakage of fluids and gases in various machinery, including turbines. These strips create a tight seal between moving parts, helping to maintain pressure and prevent contaminants from entering sensitive areas of turbine constructions. Their proper functioning is integral to the overall efficiency and longevity of the turbine.

Why High-Quality Matters

The performance of a turbine is heavily reliant on the integrity of its sealing mechanisms. High-quality seal strips offer several advantages over their lower-quality counterparts

1. Durability Seal strips made from premium materials can withstand extreme temperatures, pressure fluctuations, and environmental conditions without degrading. This durability ensures that turbines can operate continuously and efficiently over extended periods.

2. Reduced Leakage Effective sealing minimizes fluid or gas leakage, crucial for maintaining operational efficiency. Any loss in pressure or performance can lead to increased operational costs and reduced output, making high-quality seals critical for optimizing turbine performance.

high quality seal strip turbine

3. Cost-Effectiveness While high-quality seal strips may have a higher initial cost, their longevity and reliability lead to lower maintenance and replacement costs over time. Investing in quality seals helps avoid unscheduled downtimes and repairs, ultimately saving money in the long run.

4. Enhanced Safety In many turbine applications, particularly in power generation, the risk of leaks can pose hazards to both equipment and personnel. High-quality seal strips reduce these risks by providing a reliable barrier against leaks, enhancing overall safety in operation.

Types of Seal Strips Used in Turbines

Different turbine applications require specific types of seal strips tailored for their needs. Common materials include

- Rubber Often used for their elasticity and ability to conform to surfaces, rubber seals are commonly used in various turbine applications. - PTFE (Polytetrafluoroethylene) Known for its chemical resistance and low friction properties, PTFE seal strips are excellent for high-temperature applications and when compatibility with various fluids is essential.

- Silicone This material offers excellent temperature resistance and flexibility, making it a common choice for environments with extreme temperature fluctuations.

Conclusion

High-quality seal strips are indispensable in ensuring the functionality and efficiency of turbine systems. By providing durability, effectiveness in preventing leaks, safety, and long-term cost savings, they play a crucial role in turbine operation and maintenance. As the demand for reliable and efficient energy sources continues to rise, investing in high-quality sealing solutions will remain a critical focus for manufacturers and engineers alike. In an industry where performance and reliability are paramount, the importance of seal strips cannot be overstated, and their role in the longevity and efficiency of turbine mechanics will only become more significant as technology progresses.

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025