Hightech Injection LED module-size6414 | Ultra-bright, IP67

Nov . 02, 2025 01:55 Back to list

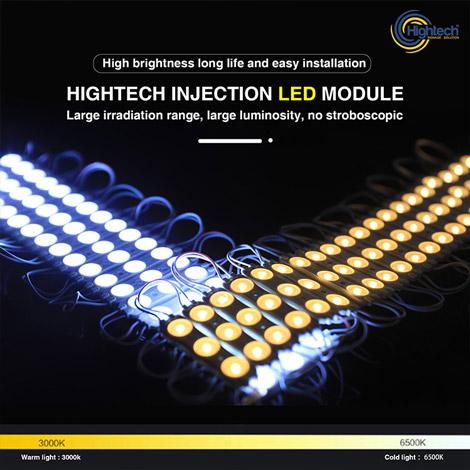

Hightech Injection LED module-size6414 | Ultra-bright, IP67

Hightech Injection LED Module-size6414 is a key solution in the manufacturing industry, specifically within Computer, communication, and other electronic equipment manufacturing industry and Manufacturing of electronic components and assemblies. This article explores how Hebei Pulongte Rubber And Plastic Technology Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Hightech Injection LED Module-size6414 Overview

- Benefits & Use Cases of Hightech Injection LED Module-size6414 in Manufacturing of electronic components and assemblies

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Hightech Injection LED Module-size6414 from Hebei Pulongte Rubber And Plastic Technology Co., Ltd.

Hightech Injection LED Module-size6414 Overview

The Hightech Injection LED Module-size6414 is a compact, injection-molded LED module designed for stable illumination and streamlined integration across computer, communication, and electronic equipment applications. Its thin, elongated footprint (aligned with a 64×14 mm class form factor) allows OEMs and EMS providers to fit consistent backlighting into tight housings, status indicators, light boxes, and HMI panels without reworking enclosure designs. By combining optical-grade materials with precise molding, the module achieves uniform light distribution and robust mechanical protection suitable for demanding assembly lines and end products.

Technically, injection-molded construction helps protect LEDs and circuitry from handling stress and environmental exposure, while the integrated lensing improves luminous consistency across diffuse surfaces. The module architecture supports common constant-voltage system designs and daisy-chain wiring, making it straightforward to standardize across product families and reduce SKU complexity. For B2B decision makers seeking repeatable quality at scale, these attributes translate into fewer assembly steps, faster takt times, and lower rework rates during final testing. Hebei Pulongte Rubber And Plastic Technology Co., Ltd. manufactures the Hightech Injection LED Module-size6414 with an emphasis on process control and reliability, offering stable lead times, OEM/ODM support, and attentive engineering collaboration to accelerate new product introductions in the Manufacturing of electronic components and assemblies segment.

Benefits & Use Cases of Hightech Injection LED Module-size6414 in Manufacturing of electronic components and assemblies

In the Manufacturing of electronic components and assemblies, the Hightech Injection LED Module-size6414 supports a wide range of applications: control-panel backlighting, equipment status indicators, instrument clusters, telecom cabinet labeling, server rack ID guidance, and edge-lit displays used on production floors. Its durable, molded housing is advantageous for jigs and fixtures that experience frequent handling, while consistent light output improves readability of labels, scales, and diagnostic interfaces—critical for quality assurance and operator safety.

Competitive advantages include compact sizing for dense assemblies, uniform luminance that reduces hot spots, and a modular electrical layout that simplifies installation and maintenance. The injection process enhances structural integrity versus simple PCB-only modules, helping resist shock and minor vibration typically present in factory environments. Color consistency and stable brightness across production lots also aid OEMs in meeting end-customer expectations for visual uniformity. Leveraging domain expertise in polymers and precision molding, Hebei Pulongte Rubber And Plastic Technology Co., Ltd. aligns the module’s optical and mechanical design with the realities of high-throughput manufacturing, enabling integrators to standardize a single lighting solution across multiple product SKUs and industrial use cases.

Cost, Maintenance & User Experience

Total cost of ownership for the Hightech Injection LED Module-size6414 is driven by energy efficiency, service life, and reduced assembly time. The compact, plug-and-play format allows technicians to install or replace modules quickly, reducing line stoppages and minimizing labor costs. Over the product lifecycle, energy savings and fewer interventions typically offset the upfront hardware cost, helping B2B buyers realize an attractive ROI—especially in applications with long daily runtimes or distributed networks of modules across multiple cabinets and panels.

Maintenance requirements are straightforward: visual inspection during scheduled line checks and basic cleaning where dust accumulation may affect optical surfaces. Feedback from customers in the computer, communication, and other electronic equipment manufacturing industry commonly highlights three outcomes: improved visual clarity for operators, faster fixture commissioning, and stable performance under normal production vibrations. With consistent build quality from Hebei Pulongte Rubber And Plastic Technology Co., Ltd., engineering teams can standardize documentation, training, and spare-parts strategies around a single, reliable module—lowering indirect costs tied to inventory management and quality incidents.

Sustainability & Market Trends in manufacturing

As manufacturers pursue higher energy efficiency, longer mean time between failures, and compliance with evolving regulations, LED modules continue to displace legacy lighting in production equipment and end devices. Global directives such as RoHS and initiatives for circularity are pushing demand for components that support lower environmental impact through longer service life and reduced power consumption. Standardized, modular lighting also aids repairability—extending product longevity and reducing waste across the supply chain.

Hebei Pulongte Rubber And Plastic Technology Co., Ltd. positions the Hightech Injection LED Module-size6414 as a forward-looking choice for OEMs and EMS providers focused on sustainability. By emphasizing durable construction, stable performance, and efficient use of materials, the company helps customers reduce energy draw and maintenance-related waste. In parallel, market trends toward smart factories and visual management (e.g., clearer signaling, guided assembly) align well with compact, uniform LED modules—enabling manufacturers to enhance operator experience, lower carbon intensity per unit produced, and support corporate ESG goals without compromising throughput or cost.

Conclusion on Hightech Injection LED Module-size6414 from Hebei Pulongte Rubber And Plastic Technology Co., Ltd.

For B2B decision makers in the computer, communication, and broader electronics sectors, the Hightech Injection LED Module-size6414 delivers a practical blend of reliability, compact design, and consistent illumination. Its injection-molded construction supports rugged factory environments and precise optical performance, while modular integration lowers installation time and lifetime ownership costs. Backed by Hebei Pulongte Rubber And Plastic Technology Co., Ltd.’s manufacturing know-how and responsive support, the module is a smart standard for backlighting, indicators, and visual aids across multiple product lines.

- Strengthen production visibility and consistency with a dependable LED module tailored for electronic components and assemblies.

- Partner with a manufacturer recognized for quality and service continuity.

- Contact us: email: 85733247@qq.com

- Visit our website: https://www.pulongte.com

-

Comprehensive Guide to White PVC Material: Benefits, Applications & Innovations

NewsNov.24,2025

-

Flat Hard Plastic PP Flexible Strips: Durable, Flexible, and Sustainable Solutions for Modern Industry

NewsNov.24,2025

-

Understanding Soft PVC Slip Cover Tuck Grip – Global Uses & Benefits

NewsNov.23,2025

-

Discover the Practical Benefits and Global Use of Square Plastic Tubes

NewsNov.23,2025

-

Understanding Led Lampshade Diffuser PC Covers – Benefits, Trends & Buying Guide

NewsNov.22,2025

-

Durable, Cost-Effective PVC Rectangular Grey Tube for Frame Solutions | Pulongte

NewsNov.22,2025