2cm J Shape Products from Leading Manufacturers for Your Business Needs

Dec . 10, 2024 19:43 Back to list

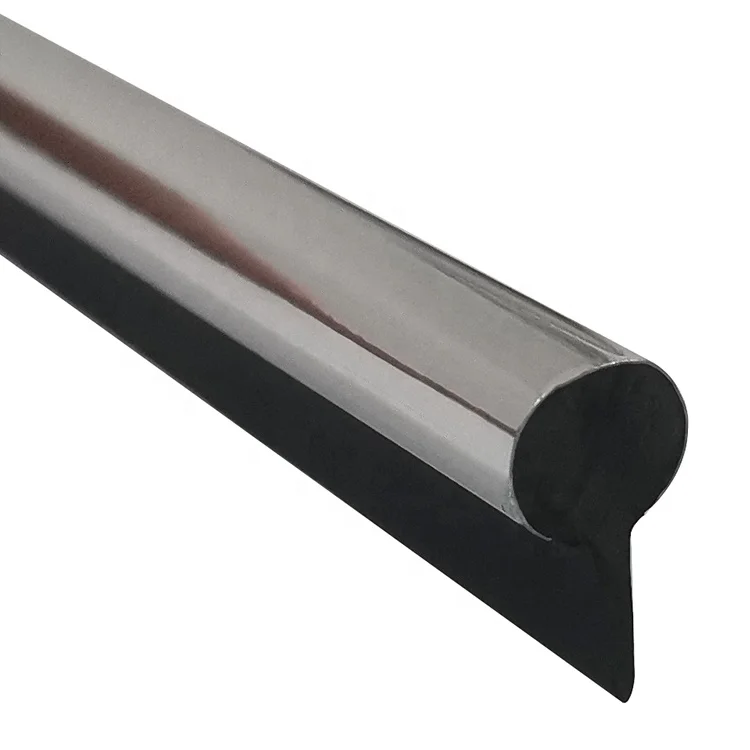

2cm J Shape Products from Leading Manufacturers for Your Business Needs

The Fascination of J-Shape Design A Focus on 2cm Factories

In the ever-evolving landscape of industrial design and manufacturing, the importance of functional and aesthetic forms cannot be understated. Among these designs, the J-shape has carved a niche for itself, particularly in the realm of 2cm factories. This article explores the significance of J-shape designs in a 2cm context, highlighting their utility, versatility, and impact on modern manufacturing processes.

Understanding the J-Shape

The J-shape, characterized by a combination of straight lines and smooth curves, is not just a visually appealing design. It serves specific purposes in various applications, ranging from furniture to automotive parts. The design’s unique curvature allows for efficient load distribution and stability, making it an ideal choice for items that require both strength and elegance.

The Role of 2cm Factories

When we talk about 2cm factories, we refer to manufacturing facilities that specialize in producing items with dimensions that are 2 centimeters in height or thickness. This compact size presents both opportunities and challenges. In a world that often favors larger dimensions for impact, the 2cm standard pushes designers and engineers to innovate continually. Here, J-shape designs can shine, providing structural integrity without compromising on stylishness, thus bridging the gap between form and function.

Applications in Various Industries

j shape 2cm factories

The versatility of the J-shape makes it suitable for various industries. For instance, in furniture design, J-shaped legs offer a modern look while ensuring stability for tables and chairs. In automotive design, J-shaped components can contribute to the overall aerodynamics of a vehicle while maintaining lower weight, enhancing fuel efficiency. In electronics, the compact size of J-shaped connectors can optimize space within devices, allowing for greater portability and functionality.

Additionally, the manufacturing processes used in 2cm factories are often adapted to accommodate the unique requirements of J-shape designs. Advanced techniques such as injection molding, CNC machining, and 3D printing enable manufacturers to create precise and intricate J-shaped parts that meet high standards of quality and performance.

Sustainability and Efficiency

As industries increasingly pivot towards sustainable practices, the J-shape also offers a pathway to eco-friendliness. The design’s ability to maximize space efficiency is critical in reducing material waste during production. Moreover, the use of recyclable materials in the manufacturing process can further minimize the environmental impact. By adopting J-shaped designs, factories can achieve both aesthetic appeal and sustainability, which is a growing demand among consumers.

Conclusion

The J-shape design, particularly in the context of 2cm factories, exemplifies a remarkable convergence of style and practicality. As industries continue to demand innovative solutions that carry both aesthetic and functional value, the popularity of J-shaped items is likely to rise. With their ability to enhance designs while ensuring structural integrity, J-shapes are here to stay, offering endless possibilities for future advancements in manufacturing. As we look ahead, embracing such designs can lead to breakthroughs that not only elevate product quality but also resonate with the eco-conscious ethos of today’s consumers.

In sum, the J-shape is more than just a design choice; it is a transformative approach to industrial aesthetics and utility, particularly evident in the innovation-driven realm of 2cm factories.

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025