Creating Engaging OEM Channel Letters for Effective Branding and Marketing Strategies

Oct . 09, 2024 13:04 Back to list

Creating Engaging OEM Channel Letters for Effective Branding and Marketing Strategies

Understanding OEM Channel Letter Making A Comprehensive Guide

In the world of signage, OEM (Original Equipment Manufacturer) channel letters have become a popular choice for businesses looking to enhance their brand visibility. These illuminated signs are often seen on storefronts, corporate buildings, and even at trade shows, making them an essential tool for attracting customers. This article delves into the process of OEM channel letter making, the benefits they offer, and the various customization options available.

What are OEM Channel Letters?

OEM channel letters are three-dimensional signs typically made from aluminum or plastic that are mounted to a wall or a surface. These letters are designed with internal lighting, allowing them to glow and stand out, especially during nighttime. The term OEM means that these letters are produced according to specific requirements set by a business, ensuring that the final product aligns perfectly with the brand's image.

The Manufacturing Process

The process of creating OEM channel letters involves several steps

1. Design The first step is to create a design that reflects the brand's identity. This is typically done using graphic design software, where colors, fonts, and dimensions are specified. It’s crucial that the design is not only visually appealing but also adheres to local regulations regarding signage.

2. Material Selection Channel letters can be made from various materials, including aluminum, stainless steel, acrylic, and polycarbonate. The choice of material can affect durability, appearance, and cost. For instance, aluminum is lightweight and resistant to rust, making it a popular choice for outdoor signs.

3. Cutting and Fabrication Once the design is finalized and materials are selected, the next step involves cutting the letters to the specified dimensions. Fabrication techniques such as laser cutting or CNC machining are commonly used to achieve precise shapes. After cutting, the letters are assembled, and any internal components, such as LED lighting, are installed.

4. Finishing The final stage in the manufacturing process includes finishing touches like paint, polish, or protective coatings. This not only enhances the visual appeal but also adds a layer of protection against environmental elements.

oem channel letter making

5. Installation Once the channel letters are completed, they are ready for installation. Proper installation is crucial to ensure that the letters are securely mounted and that the electrical components are safely connected.

Benefits of OEM Channel Letters

Investing in OEM channel letters offers numerous advantages

- Enhanced Visibility The illumination feature ensures that your brand is visible day and night, helping attract more customers.

- Customization OEM channel letters can be tailored to meet specific branding requirements, allowing for greater creative freedom.

- Durability Quality materials used in manufacturing ensure that these signs withstand harsh weather conditions, lasting for years without significant wear.

- Professional Appeal Well-made channel letters enhance the overall aesthetic of a business, communicating professionalism and reliability.

Conclusion

OEM channel letter making is an intricate process that combines design, craftsmanship, and technology to create impactful signage. By understanding the steps involved and the benefits these signs provide, businesses can make informed decisions about incorporating channel letters into their branding strategies. Whether for a storefront or a corporate building, OEM channel letters can significantly enhance brand recognition and customer engagement.

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

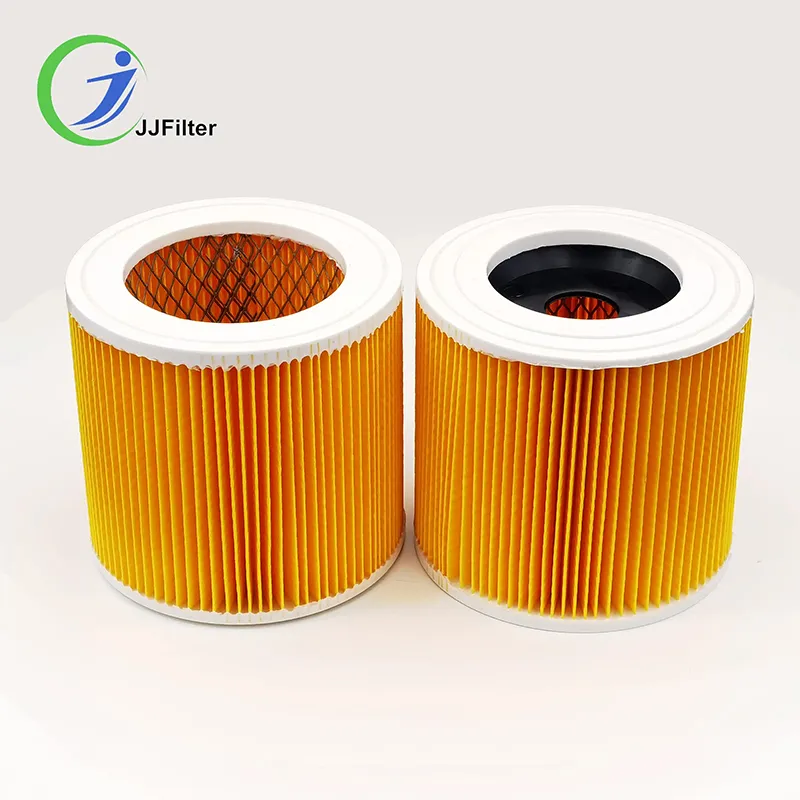

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025