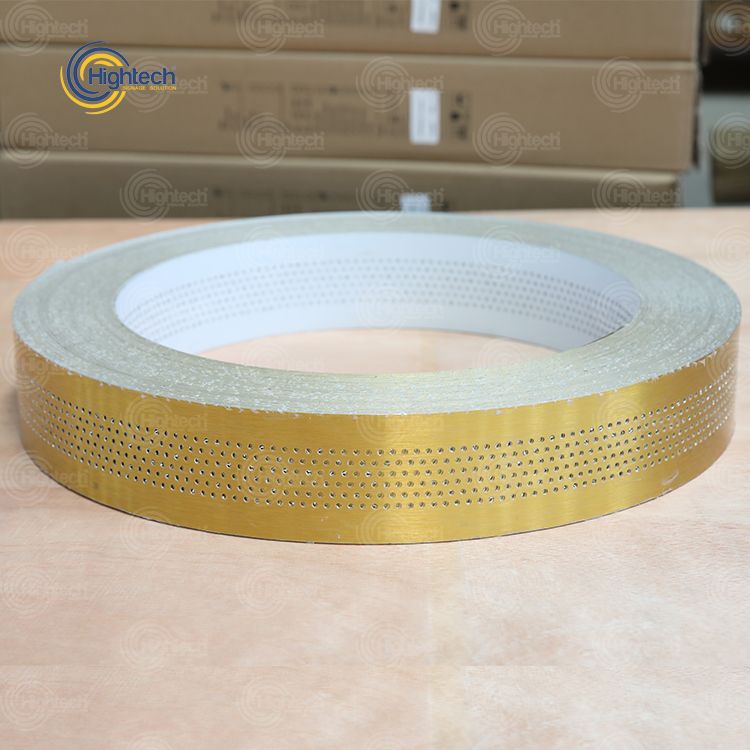

oem edge sealing silicone seam

Oct . 12, 2024 09:33 Back to list

oem edge sealing silicone seam

The Importance of OEM Edge Sealing Silicone Seam Solutions

In various manufacturing and industrial processes, the integrity and durability of products are paramount. One often overlooked but critical aspect of this is the edge sealing process, particularly when it comes to adhesive solutions like OEM edge sealing silicone seams. This article will explore the advantages of using silicone for edge sealing, the specific applications of OEM solutions, and why manufacturers should consider integrating these practices into their production lines.

Understanding Edge Sealing

Edge sealing is a technique used to protect the edges of materials from environmental factors such as moisture, dust, and mechanical wear. In industries ranging from automotive to electronics and construction, seams and edges need to be sealed properly to ensure long-lasting performance. The choice of sealing material plays a vital role in determining the effectiveness of this process.

The Role of Silicone

Silicone is a versatile material that has become the go-to choice for edge sealing due to its superior properties. One significant advantage of silicone is its excellent weather resistance. It can withstand extreme temperatures, UV radiation, and humidity, making it ideal for both indoor and outdoor applications. In addition, silicone offers great elasticity, allowing it to accommodate movement and thermal expansion, which is crucial in maintaining a strong seal over time.

Moreover, silicone is chemically inert, meaning it won't react with other substances, making it safe for various applications, including food and medical devices. This characteristic ensures that the seal remains intact and does not compromise the integrity of the enclosed materials.

OEM Solutions Tailored for Maximum Efficiency

oem edge sealing silicone seam

Original Equipment Manufacturers (OEM) specialize in creating components and products that suit the specific needs of other companies. When it comes to edge sealing, OEM solutions can be customized to meet the unique requirements of different industries. This not only improves efficiency but also enhances the overall quality of the final product.

OEM silicone edge sealing solutions can be designed for specific applications, accounting for factors such as substrate material, environmental conditions, and performance requirements. This customization ensures that manufacturers can rely on the sealing solutions to perform optimally under various conditions, ultimately leading to increased product longevity and reduced warranty claims.

Applications in Various Industries

The application of OEM edge sealing silicone seams extends across numerous sectors. In the automotive industry, silicone seals are used for windows, doors, and various body parts to prevent water ingress and reduce noise. For electronic devices, silicone sealing provides a protective barrier against dust and moisture, ensuring the functionality and reliability of the products.

In the construction sector, silicone edge sealing is employed in windows and doors to provide insulation and improve energy efficiency. Furthermore, in home appliances, silicone is used to seal edges in refrigerators, ovens, and other devices, protecting against spills and enhancing durability.

Conclusion

In conclusion, OEM edge sealing silicone seams represent a critical component in achieving high-quality, durable products across various industries. The benefits of using silicone, such as its weather resistance, elasticity, and chemical inertness, make it an ideal choice for edge sealing applications. By opting for OEM solutions, manufacturers can ensure that they meet the specific needs of their markets, ultimately enhancing product performance and longevity. As industries continue to evolve, the importance of effective edge sealing cannot be overstated, making silicone seams a wise investment for future-proofing products.

-

Premium Car Trim Strip - Top Car Moulding Trim Strip Exporters & 3 Car Moldings Manufacturers

NewsJul.08,2025

-

High-Quality Sponge Seal Solutions Leading Sponge Door Seal Manufacturer & Service

NewsJul.08,2025

-

U Shape Chrome Trim Strip Manufacturer & Exporter High-Quality Factory Products

NewsJul.07,2025

-

High-Quality LED Neon Light Supplier – Flexible & Color Changing Neon Strip Lights for Versatile Applications

NewsJul.07,2025

-

High-Quality White Transparent Silicone Strip Reliable Exporter & Factory Price

NewsJul.07,2025

-

Premium U Shape Chrome Trim Strip – Reliable Factory & Exporter for Automotive & Home Décor

NewsJul.06,2025