Custom Flat PVC Strips for OEM Applications in Various Industries

Oct . 08, 2024 10:34 Back to list

Custom Flat PVC Strips for OEM Applications in Various Industries

Understanding OEM Flat PVC Strips Versatility in Manufacturing

In the modern manufacturing landscape, materials that combine durability, flexibility, and cost-effectiveness are highly valued. One such material, increasingly popular across various industries, is the OEM (Original Equipment Manufacturer) flat PVC (Polyvinyl Chloride) strip. These strips have gained a solid reputation for their versatility and practicality, making them an essential component in various applications.

What is OEM Flat PVC Strip?

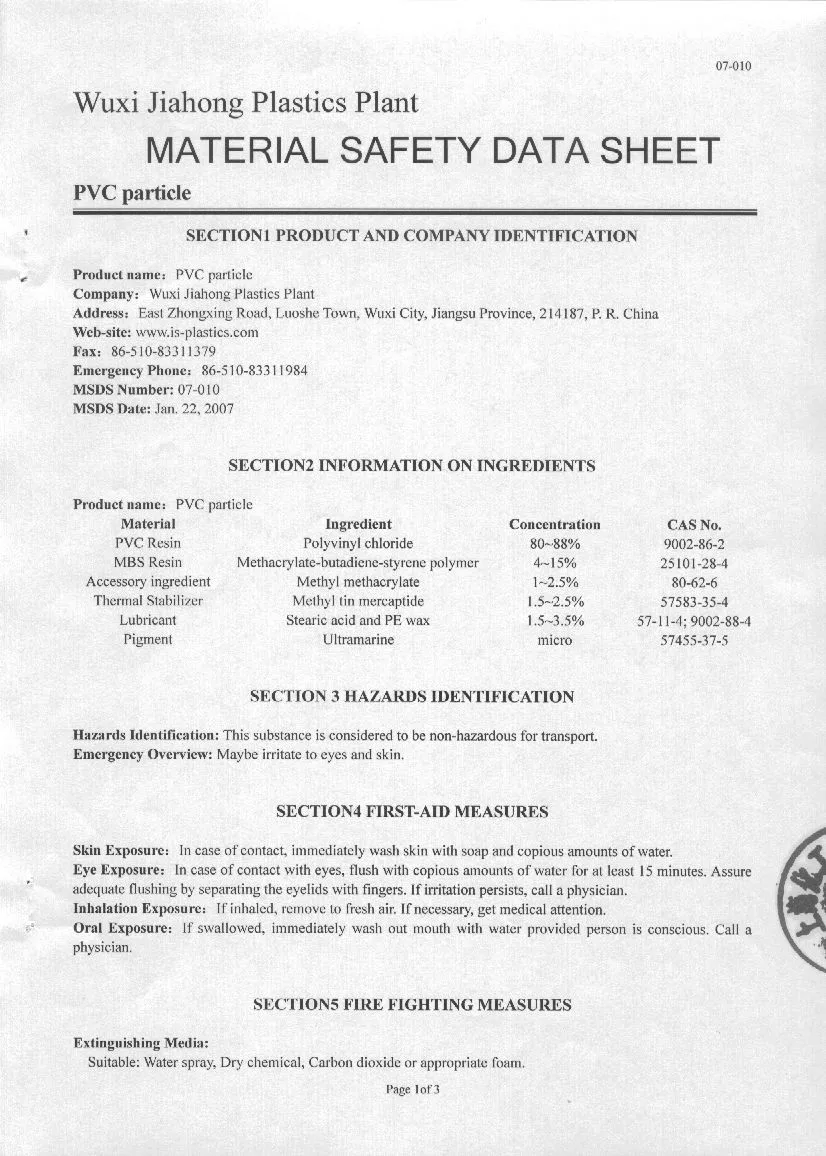

OEM flat PVC strips are manufactured specifically for specific applications based on client specifications. These strips are created from high-quality PVC, a synthetic plastic polymer known for its robustness and resilience. The term ‘flat’ refers to the shape of the strips, which typically display a consistent thickness and width, making them easy to handle and integrate into existing manufacturing processes.

Applications of PVC Strips

The applications of OEM flat PVC strips are wide-ranging. From packaging and construction to automotive and medical fields, the uses of these strips can be seen throughout various sectors

1. Packaging In the packaging industry, PVC strips are commonly used as protective barriers. They help in sealing products from dust, moisture, and other contaminants while allowing for visibility. Their flexibility and strength make them ideal for creating custom-sized packaging solutions.

2. Construction In construction, flat PVC strips are utilized for edge protection and as joint covers. They are effective in preventing damage to edges and corners during transport or installation, thereby enhancing the longevity of the structures.

oem flat pvc strip

3. Automotive In automotive manufacturing, OEM flat PVC strips serve as protective strips along door edges and bumpers. They help absorb minor impacts and protect the vehicle’s paintwork, contributing to a vehicle's overall aesthetic and durability.

4. Medical The medical industry also benefits from the use of flat PVC strips, particularly in the manufacturing of medical devices and equipment. Their ability to be sterilized and resistant to various chemicals makes them suitable for applications that require high standards of hygiene.

Advantages of PVC Strips

The appeal of OEM flat PVC strips lies in several inherent advantages. First and foremost is their durability; PVC is resistant to many chemicals, UV light, and weathering, which means these strips can endure harsh environments without significant wear. Furthermore, they are lightweight yet remarkably strong, adding to their usability in multiple sectors.

Another significant advantage is the customization aspect. OEM manufacturers can tailor the strips in terms of size, thickness, color, and printing, making it easy for businesses to integrate them seamlessly into their products. This flexibility ensures that companies can meet their specific needs without compromising on quality.

Additionally, the manufacturing process of flat PVC strips is relatively cost-effective. This aspect is crucial in industries where margins can be tight, allowing companies to save on overheads while still accessing high-quality materials.

Conclusion

In summary, OEM flat PVC strips are a dynamic solution for various industrial needs. Their versatility, combined with their durability and customization options, makes them invaluable in today's manufacturing ecosystem. As industries continue to evolve and seek better materials to enhance their products, flat PVC strips will likely remain an essential component driving innovation and efficiency across multiple sectors. Whether for packaging, construction, automotive applications, or medical devices, these strips exemplify how a simple material can satisfy complex manufacturing requirements.

-

Premium Car Trim Strip - Top Car Moulding Trim Strip Exporters & 3 Car Moldings Manufacturers

NewsJul.08,2025

-

High-Quality Sponge Seal Solutions Leading Sponge Door Seal Manufacturer & Service

NewsJul.08,2025

-

U Shape Chrome Trim Strip Manufacturer & Exporter High-Quality Factory Products

NewsJul.07,2025

-

High-Quality LED Neon Light Supplier – Flexible & Color Changing Neon Strip Lights for Versatile Applications

NewsJul.07,2025

-

High-Quality White Transparent Silicone Strip Reliable Exporter & Factory Price

NewsJul.07,2025

-

Premium U Shape Chrome Trim Strip – Reliable Factory & Exporter for Automotive & Home Décor

NewsJul.06,2025