Plastic Door Seal Strip Manufacturer for Quality Home and Industrial Solutions

Sep . 24, 2024 13:20 Back to list

Plastic Door Seal Strip Manufacturer for Quality Home and Industrial Solutions

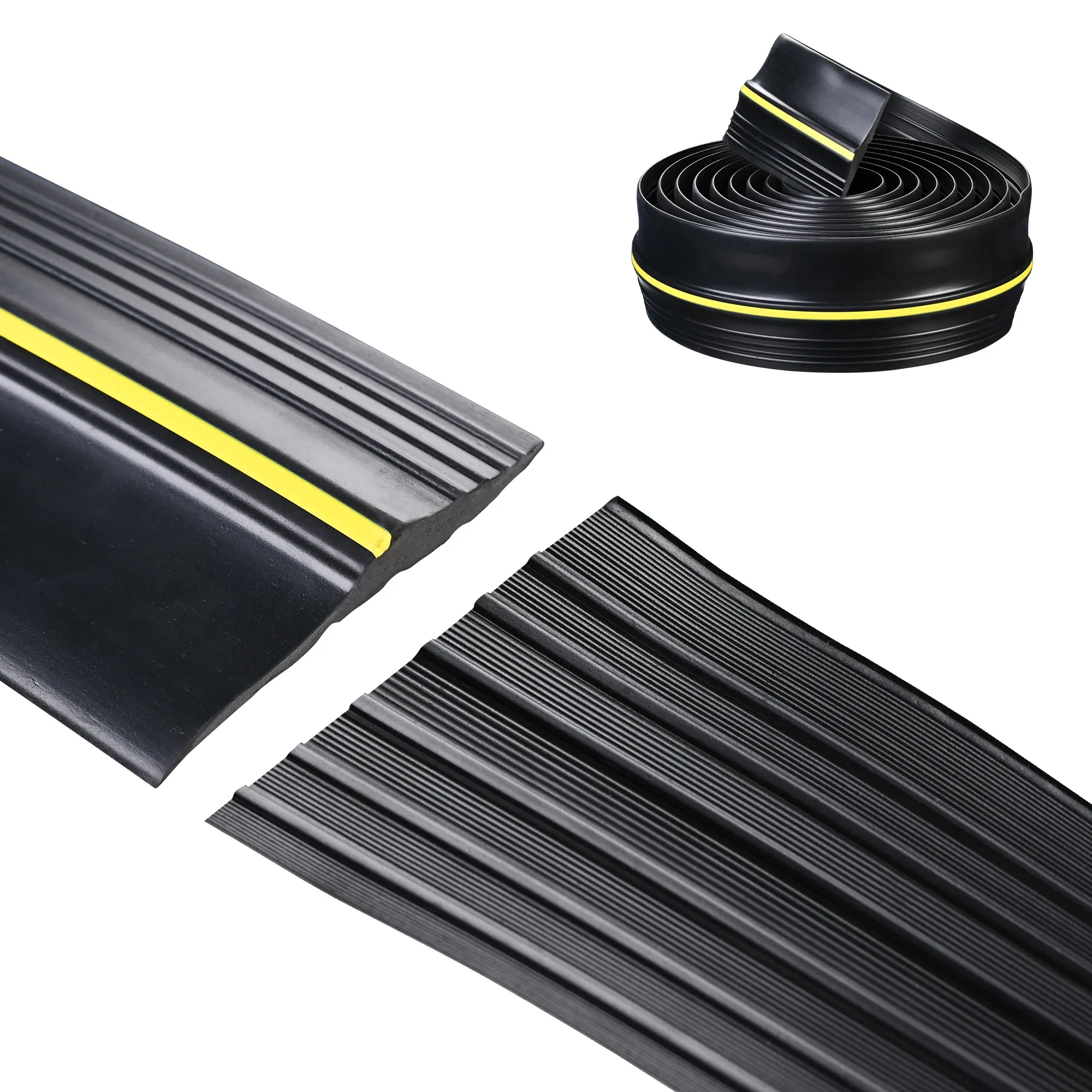

Exploring the Benefits of Plastic Door Seal Strips A Look at the Factory Production Process

In today's world, energy efficiency and home comfort are paramount concerns for homeowners and businesses alike. One effective solution to address these issues is the use of plastic door seal strips. These innovative products are designed to seal gaps around doors, thereby preventing drafts and enhancing insulation. This article delves into the importance of plastic door seal strips and provides an overview of the factory production process that brings these essential items to market.

Exploring the Benefits of Plastic Door Seal Strips A Look at the Factory Production Process

The production of plastic door seal strips begins in specialized factories equipped with advanced machinery. The process typically starts with the selection of high-quality raw materials, such as PVC (polyvinyl chloride) or EPDM (ethylene propylene diene monomer rubber), which are both known for their durability and flexibility. These materials are then processed and compounded to enhance their properties, ensuring they can effectively withstand temperature fluctuations and resist aging over time.

plastic door seal strip factory

Once the materials are prepared, they are fed into extrusion machines, which mold them into the specific shapes and sizes required for different door configurations. Customization is a key aspect of production, as manufacturers recognize that not all doors are the same. Various profiles, including adhesive-backed strips or claw types for insertion into channels, are produced to meet customers’ needs.

After extrusion, the seal strips undergo a stringent quality control process. Each batch is tested for durability, flexibility, and sealing effectiveness. This ensures that the finished products meet industry standards and customer expectations. Once approved, the strips are cut to size, packaged, and shipped to distributors, retailers, or directly to consumers.

The impact of plastic door seal strips extends beyond individual spaces. By reducing energy consumption and improving indoor air quality, these products contribute to environmental sustainability. A well-sealed door can significantly lower energy waste, making homes and businesses more eco-friendly.

In conclusion, plastic door seal strips are indispensable tools for enhancing comfort and efficiency in any space. The factory production process that creates these products is a testament to advanced manufacturing techniques and a commitment to quality. As we continue to prioritize energy conservation and effective insulation, plastic door seal strips will play a crucial role in our homes and workplaces, proving that small improvements can lead to significant benefits.

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025