pvc extrusion profile supplier

Nov . 15, 2024 22:41 Back to list

pvc extrusion profile supplier

Understanding PVC Extrusion Profile Suppliers A Comprehensive Guide

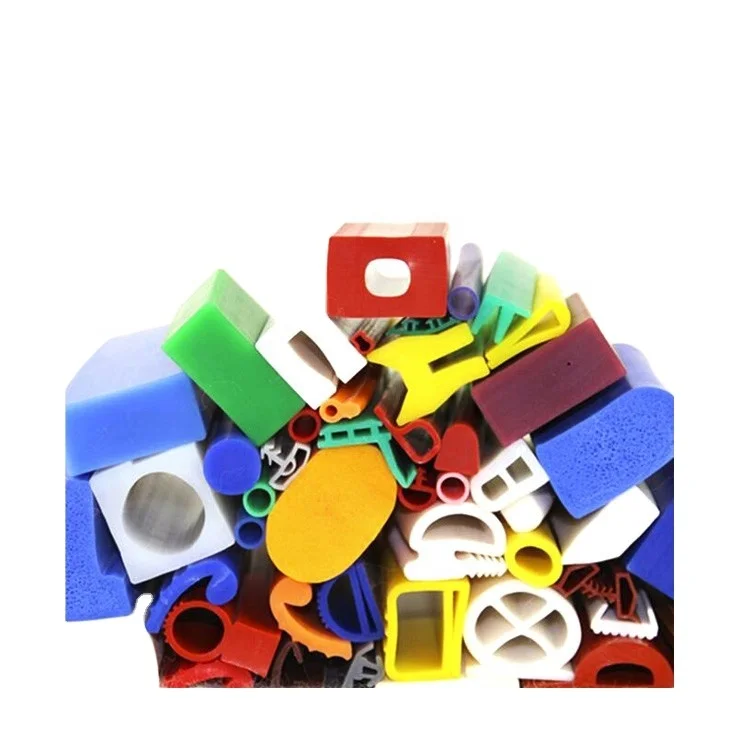

Polyvinyl chloride (PVC) is one of the most versatile plastic materials used in various applications across industries. From construction to automotive to packaging, PVC's properties make it an ideal choice for many products. A significant method of processing PVC is through extrusion, where the material is shaped into continuous profiles. In this article, we will explore the role of PVC extrusion profile suppliers, what they offer, and why they are essential in the manufacturing supply chain.

What is PVC Extrusion?

PVC extrusion is a manufacturing process where PVC resin is heated and pushed through a die to create long shapes or profiles. This method allows for the creation of complex shapes that can be used in various applications like window frames, plumbing pipes, and decking materials. The final product can have different properties, depending on the additives used during the extrusion process, which can enhance its durability, flexibility, and resistance to environmental factors.

Role of PVC Extrusion Profile Suppliers

PVC extrusion profile suppliers play a critical role in the supply chain by providing manufacturers with the necessary extruded profiles for their production needs. These suppliers not only provide the raw extruded materials but also ensure that the products meet the required standards and specifications for different applications.

1. Product Variety Suppliers typically offer a wide range of PVC extrusion profiles, including standard profiles and custom designs tailored to meet specific industrial requirements. This variety ensures that businesses can find the right materials for their specific applications.

2. Quality Control Reputable suppliers conduct rigorous quality control measures to ensure that their profiles comply with industry standards. This includes testing for strength, durability, and resistance to various environmental factors, ensuring that the end-user receives a reliable product.

3. Technical Support Many suppliers provide technical assistance and expertise in selecting the right profiles based on the application needs. This guidance can be invaluable for businesses that may not know the best material for their projects.

4. Cost-Effectiveness By sourcing PVC profiles from specialized suppliers, manufacturers can reduce costs associated with production and material wastage. Suppliers often have established relationships with raw material providers, which can lead to better pricing and more efficient supply chains.

pvc extrusion profile supplier

5. Sustainability Practices With increasing awareness of environmental issues, many PVC extrusion profile suppliers are adopting sustainable practices. This includes using recycled materials and promoting eco-friendly formulations. Manufacturers looking to reduce their carbon footprint can benefit from partnering with suppliers that prioritize sustainability.

Choosing the Right Supplier

When selecting a PVC extrusion profile supplier, several factors should be considered

- Experience and Reputation Choose suppliers with a proven track record in the industry. Their experience often translates into better product quality and customer service.

- Product Range Ensure the supplier offers a comprehensive range of profiles that suit your specific needs.

- Custom Capabilities If you need custom designs, verify that the supplier can accommodate those requirements.

- Certifications Look for suppliers that hold relevant certifications, indicating compliance with industry standards.

- Delivery and Service Timely delivery and responsive customer service are critical, especially for manufacturers working under tight deadlines.

Conclusion

PVC extrusion profile suppliers are vital contributors to numerous industries, providing essential materials that form the backbone of various products. By selecting a reputable supplier, manufacturers can ensure they receive high-quality profiles that meet their specific needs while benefiting from technical support and cost savings. As industries continue to evolve and demand for durable, sustainable materials increases, the importance of reliable PVC extrusion profile suppliers will only grow. By forging strong partnerships with these suppliers, businesses can enhance their production capabilities and overall project success.

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025