Reliable Suppliers of EPDM Sealing Strips for Various Industrial Applications and Needs

Jul . 28, 2024 00:20 Back to list

Reliable Suppliers of EPDM Sealing Strips for Various Industrial Applications and Needs

EPDM Sealing Strip Suppliers Ensuring Quality and Reliability

In today’s competitive marketplace, the demand for high-performance sealing solutions is paramount. Among various materials available for sealing applications, EPDM (Ethylene Propylene Diene Monomer) has garnered significant attention due to its exceptional properties. As a result, the role of EPDM sealing strip suppliers has become increasingly vital for industries ranging from automotive to construction.

Understanding EPDM

EPDM is a type of synthetic rubber known for its outstanding resistance to UV radiation, ozone, and extreme weather conditions. Its flexibility at low temperatures and robust performance at high temperatures make it an ideal choice for sealing strips in various applications. Beyond its durability, EPDM provides excellent electrical insulating properties, which is crucial for certain electronic components. This versatility is a key reason why many manufacturers prefer EPDM sealing solutions.

The Importance of Choosing Reliable Suppliers

Choosing the right EPDM sealing strip supplier is critical for ensuring the quality and performance of the seals. A reputable supplier will offer products that meet industry standards and specifications, providing the necessary certifications and compliance documents. This is particularly important in sectors such as aerospace and automotive, where precision and reliability are non-negotiable. Suppliers that prioritize quality control and testing of their products are invaluable partners in achieving excellent results.

Key Factors to Consider When Selecting a Supplier

1. Experience and Reputation Investigate the supplier's market experience and reputation. Established suppliers often have a track record of providing reliable products and services. Customer reviews and testimonials can provide insight into their performance.

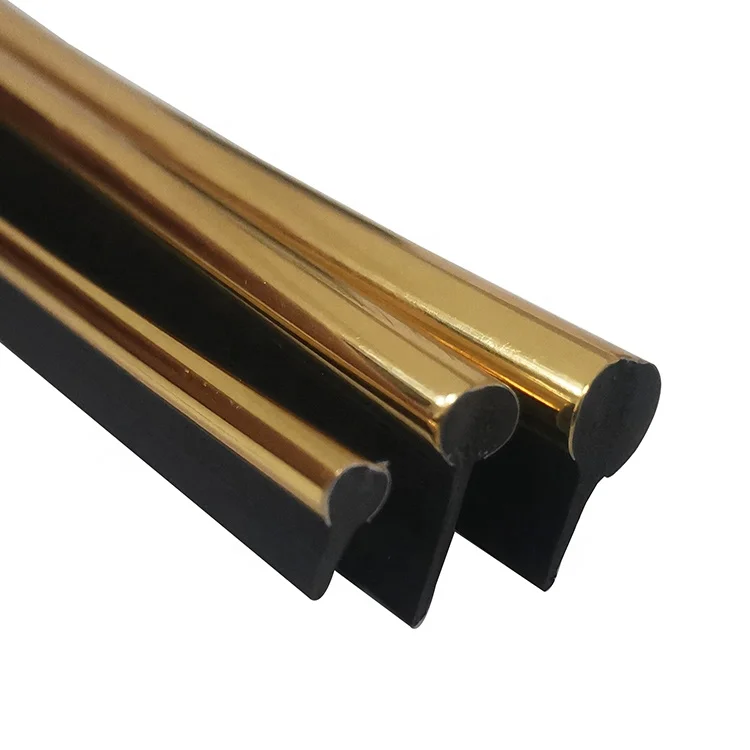

epdm sealing strip supplier

2. Product Range A good supplier should offer a wide range of EPDM sealing solutions. This includes different sizes, shapes, and customization options, allowing industries to find the perfect fit for their specific requirements.

3. Quality Assurance Ensure that the supplier has robust quality assurance processes in place. Look for suppliers that follow ISO certification standards, as this demonstrates their commitment to quality and consistency.

4. Technical Support Reliable suppliers often provide technical support to help customers choose the right sealing solutions for their applications. This assistance can be crucial in troubleshooting and optimizing seal performance.

5. Pricing and Availability While cost should not be the only factor, it's essential to balance quality with affordability. A supplier’s ability to deliver products promptly is also critical to maintaining operational efficiency in your business.

Industries Benefiting from EPDM Sealing Strips

EPDM sealing strips find applications across various industries. In the automotive sector, they are used in weather stripping around doors and windows, preventing water and air leaks. In construction, EPDM seals are used for roofing systems, ensuring buildings remain airtight and weatherproof. Additionally, the HVAC industry relies on EPDM seals for duct systems, enhancing energy efficiency.

Conclusion

The significance of EPDM sealing strips cannot be understated, as they play a crucial role in ensuring the durability and efficiency of a wide range of products. As industries continue to evolve, the demand for high-quality sealing solutions will only increase. By selecting trustworthy EPDM sealing strip suppliers, businesses can secure reliable products that not only meet their immediate needs but also contribute to long-term success. Investing time in researching and partnering with the right supplier will undoubtedly pay dividends in product performance and customer satisfaction.

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025