High-Quality Rubber Gasket Seal Strips for Reliable Sealing Solutions

Sep . 28, 2024 17:45 Back to list

High-Quality Rubber Gasket Seal Strips for Reliable Sealing Solutions

The Importance of Rubber Gasket Seal Strips in Various Applications

In a world that is increasingly reliant on effective sealing solutions, rubber gasket seal strips play a crucial role across various industries. These versatile components are essential for creating airtight and watertight seals, which help prevent leaks and enhance the overall efficiency of equipment. This article will delve into the benefits, applications, and best practices for using rubber gasket seal strips, emphasizing their significance in modern engineering and manufacturing.

Understanding Rubber Gasket Seal Strips

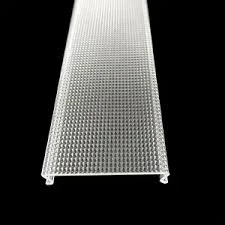

Rubber gasket seal strips are flexible strips made from various types of rubber, including silicone, neoprene, EPDM, and nitrile. These materials are chosen for their elasticity and durability, allowing them to effectively compress and adapt to irregular surfaces. The primary function of these strips is to fill the gap between two mating surfaces, creating a barrier that prevents the escape of gases, liquids, and contaminants. Their ability to withstand a wide range of temperatures and chemical exposures makes them ideal for industrial applications.

Benefits of Rubber Gasket Seal Strips

One of the most significant advantages of rubber gasket seal strips is their ability to create a tight seal without the need for additional adhesives or complicated installation processes. This not only saves time during assembly but also ensures a reliable seal that reduces the risk of leaks. Additionally, rubber gaskets exhibit excellent resistance to aging, UV radiation, and various chemicals, prolonging their lifespan and minimizing the need for frequent replacements.

Another benefit of rubber gasket seal strips is their versatility. They can be manufactured in various shapes, sizes, and thicknesses, allowing for customized solutions tailored to specific applications. This adaptability makes them suitable for use in a wide range of industries, from automotive and aerospace to food processing and pharmaceuticals.

Applications of Rubber Gasket Seal Strips

rubber gasket seal strip service

The applications of rubber gasket seal strips are vast and varied. In the automotive industry, they are commonly used in engine components, doors, and windows to ensure a tight seal against water and air leaks. This not only enhances vehicle performance but also improves fuel efficiency and reduces noise levels.

In the aerospace sector, rubber gasket seal strips are critical for maintaining the integrity of aircraft systems, including fuel tanks and hydraulic systems. Their ability to withstand extreme temperatures and pressures ensures that these systems operate safely and efficiently.

The food and beverage industry also benefits from rubber gasket seal strips. Food-safe rubber materials are used to create seals in processing equipment to prevent contamination and maintain hygiene standards. This is particularly important in industries where compliance with health regulations is critical.

Best Practices for Installation and Maintenance

To ensure optimal performance of rubber gasket seal strips, proper installation and maintenance are essential. Before installation, it is crucial to clean the mating surfaces thoroughly and remove any debris or old gasket material to ensure a good seal.

During installation, the gasket strip should be positioned carefully to avoid twisting or stretching, which can compromise the seal. Once installed, regular inspections should be conducted to check for signs of wear or damage. Replacing worn gaskets promptly can prevent leaks and extend the lifespan of the equipment.

Conclusion

Rubber gasket seal strips are integral components in numerous applications, providing effective sealing solutions that enhance efficiency and safety. Their versatility, durability, and ease of installation make them a preferred choice in various industries. By understanding their importance and implementing best practices for installation and maintenance, businesses can optimize their operations and ensure long-lasting performance in their sealing processes. As technology advances, it will be exciting to see how rubber gasket seal strips continue to evolve, meeting the ever-growing demands of modern engineering.

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025