seal strip factories

Nov . 04, 2024 22:55 Back to list

seal strip factories

The Importance of Seal Strip Factories in Modern Manufacturing

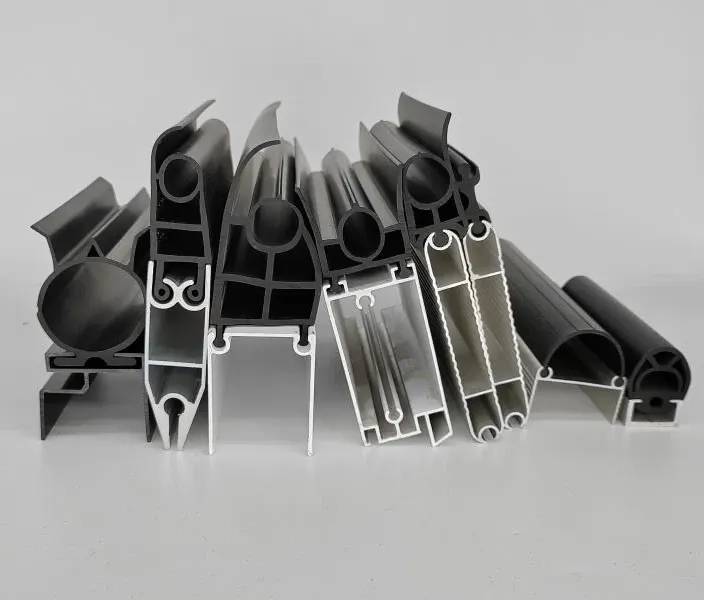

In today’s rapidly evolving manufacturing landscape, seal strip factories play a crucial role in ensuring product integrity and operational efficiency across various industries. Seal strips, often made of rubber, foam, or silicone materials, serve as essential components in numerous applications, including automotive, construction, electronics, and appliances. Their primary function is to provide effective sealing solutions that protect against dust, moisture, air, and sound. In this article, we will explore the significance of seal strip factories and their impact on product quality and industry standards.

The Role of Seal Strips

Seal strips are vital for creating airtight and watertight seals in products ranging from cars to windows and doors. In the automotive industry, for instance, seal strips ensure that vehicles are sufficiently insulated from external elements, enhancing comfort and safety for passengers. The proper installation of seal strips can lead to reduced noise levels, improved energy efficiency, and enhanced longevity of vehicles. Similarly, in the construction sector, seal strips contribute to the energy efficiency of buildings by sealing gaps around windows and doors, preventing air leaks that can lead to higher heating and cooling costs.

In the electronics industry, seal strips are essential for protecting sensitive components from moisture and dust, which can lead to product failure or decreased performance. The versatility of seal strips allows manufacturers to customize them for specific applications, including the protection of delicate electronic devices and the creation of airtight containers for sensitive chemical products.

Innovations in Seal Strip Manufacturing

With advancements in materials science and manufacturing technology, seal strip factories are constantly evolving. The introduction of new materials, such as thermoplastic elastomers (TPE), has enhanced the performance characteristics of seal strips. These materials not only offer excellent sealing properties but also exhibit resilience to extreme temperatures and environmental conditions. Additionally, advancements in manufacturing techniques, such as extrusion and molding, have enabled high-volume production of seal strips with precise dimensions and quality consistency.

Automation plays a significant role in modern seal strip factories, allowing for faster production times and reduced labor costs. State-of-the-art machinery can produce seal strips with intricate designs and specifications, meeting the diverse needs of customers while ensuring minimal waste. This shift towards automation is essential in maintaining competitive advantage in a global market where efficiency and cost-effectiveness are paramount.

seal strip factories

Quality Control and Standards

Quality control is a critical aspect of seal strip production. Factories must adhere to international standards and regulations to ensure that their products meet the specific requirements of different industries. For instance, automotive seal strips must comply with stringent safety and durability tests to ensure they can withstand harsh conditions without failing.

To maintain high-quality standards, many seal strip factories invest in rigorous testing protocols throughout the manufacturing process. These tests assess various parameters, such as tensile strength, compression set, and resistance to environmental factors. By implementing comprehensive quality management systems, factories can minimize defects and enhance customer satisfaction.

The Future of Seal Strip Factories

Looking ahead, the future of seal strip factories appears promising. As industries continue to prioritize sustainability and eco-friendly practices, the demand for biodegradable and recyclable seal strip materials is likely to grow. Manufacturers are expected to invest in research and development to create innovative sealing solutions that meet both performance and environmental standards.

Furthermore, with the increasing focus on energy efficiency and product longevity, seal strips will remain an integral part of product design across various sectors. As technologies advance, the integration of smart materials that can adapt to changing environmental conditions may revolutionize seal strip applications, providing even better sealing solutions.

Conclusion

In summary, seal strip factories are essential to modern manufacturing, playing a vital role in the functionality and durability of countless products. With ongoing innovations in materials and manufacturing techniques, these factories are well-positioned to meet the challenges of a dynamic market. By prioritizing quality control and sustainability, seal strip manufacturers can continue to contribute significantly to the success of various industries, ensuring a future where products are not only effective but also environmentally responsible.

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025