seal strip turbine suppliers

Oct . 12, 2024 09:01 Back to list

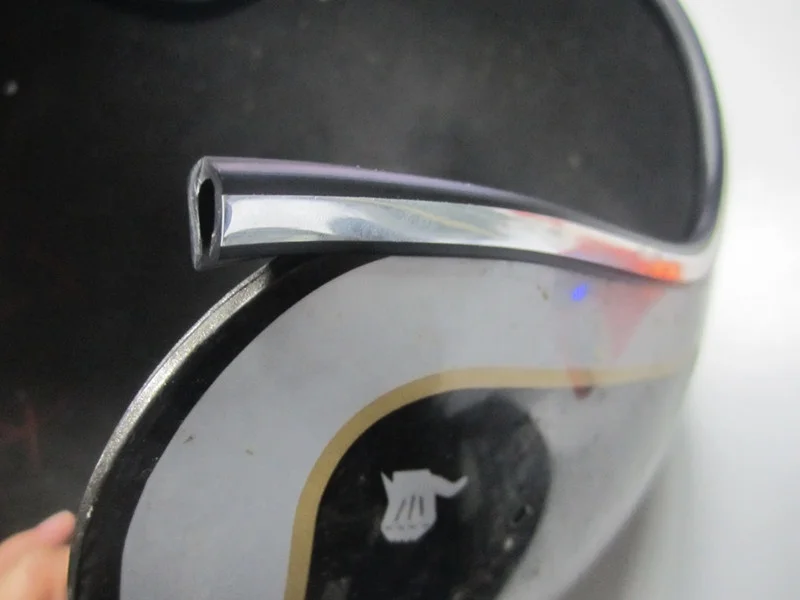

seal strip turbine suppliers

The Importance of Seal Strip Turbines and Their Suppliers

In the realm of mechanical engineering and hydrodynamics, turbines play a crucial role in energy conversion and fluid mechanics. Among the various components that enhance the efficiency and functionality of turbines, seal strips are vital. These components serve to prevent fluid leakage, maintain pressure integrity, and ensure optimal performance. Over recent years, the demand for high-quality seal strip turbine suppliers has surged, driven by advancements in technology and the increasing need for sustainable energy solutions.

Understanding Seal Strips in Turbines

Seal strips function as barriers that prevent unwanted fluid from escaping or entering a turbine system. They are typically made from durable materials such as rubber, silicone, or specialized polymers that can withstand extreme temperatures and pressures. The efficiency of a turbine can be significantly compromised if the seal strips are inadequate or poorly manufactured. Therefore, high-performance seal strips are essential for both the reliability and longevity of turbine operations.

The role of seal strips extends to various types of turbines, including steam, gas, and hydro turbines. Each turbine type has specific sealing requirements based on operational environments and fluid properties. High-quality seal strips not only improve the efficiency of energy generation but also contribute to the overall safety and environmental compliance of industrial operations.

The Growth of the Seal Strip Supplier Market

As industries increasingly prioritize efficiency and sustainability, the market for seal strip turbine suppliers has experienced exponential growth. Companies are seeking suppliers that offer innovative sealing solutions tailored to the evolving demands of the turbine industry. This has led to an influx of specialized manufacturers that focus on delivering high-quality materials and precision-engineered components.

One of the driving factors behind this market expansion is the rise of renewable energy sources. With the global shift towards wind, hydro, and other green energy solutions, the demand for advanced turbine technologies has skyrocketed. As a result, the need for effective seal strips that can operate efficiently in these systems has become paramount. Suppliers that can provide custom solutions to meet specific turbine requirements are increasingly favored, allowing businesses to enhance their operational efficiency while minimizing maintenance costs.

seal strip turbine suppliers

Selecting the Right Supplier

When selecting a seal strip supplier, there are several critical factors to consider. First and foremost, the quality of materials used by the supplier should be assessed. High-quality materials ensure that seal strips can resist wear and withstand the physical challenges presented by turbine operations. Additionally, certifications and compliance with industry standards are essential indicators of a supplier's reliability.

Another factor is the supplier’s capability to offer custom solutions. Many turbine applications require specialized seal designs to fit unique operational requirements. Suppliers that provide engineering support and collaborate closely with their clients often prove to be more reliable partners.

Furthermore, understanding a supplier's reputation and history in the industry is vital. Companies should look for suppliers with positive track records, positive client testimonials, and a history of innovation within the turbine sealing sector.

Conclusion

The significance of seal strip turbines and their suppliers cannot be overstated in today’s fast-paced industrial environment. As industries pivot towards efficiency and sustainability, the demand for high-quality seal strips is set to grow. The continued evolution of turbine technologies will necessitate reliable suppliers who can meet the intricate demands of modern energy systems.

Investing time in finding the right seal strip turbine supplier can lead to enhanced operational performance, reduced downtime, and increased profitability. The right partnerships with skilled suppliers will not only provide businesses with the essential components they need but also contribute to the larger goal of sustainable energy production for future generations. As the market continues to evolve, the collaboration between manufacturers and suppliers will be instrumental in driving innovation and efficiency in the turbine industry.

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025