Shower Glass Frame Sealing Strip Manufacturer for High-Quality and Durable Solutions

Nov . 28, 2024 02:35 Back to list

Shower Glass Frame Sealing Strip Manufacturer for High-Quality and Durable Solutions

The Importance and Production of Shower Glass Frame Seal Strips

In modern bathroom design, the aesthetics and functionality of shower enclosures play a crucial role. One often overlooked yet essential component of these structures is the shower glass frame seal strip. These strips are vital for ensuring a water-tight seal, enhancing decor, and providing additional safety in shower spaces. Understanding the significance of shower glass frame seal strips and the intricacies of their production can offer insights into their value in contemporary bathrooms.

What are Shower Glass Frame Seal Strips?

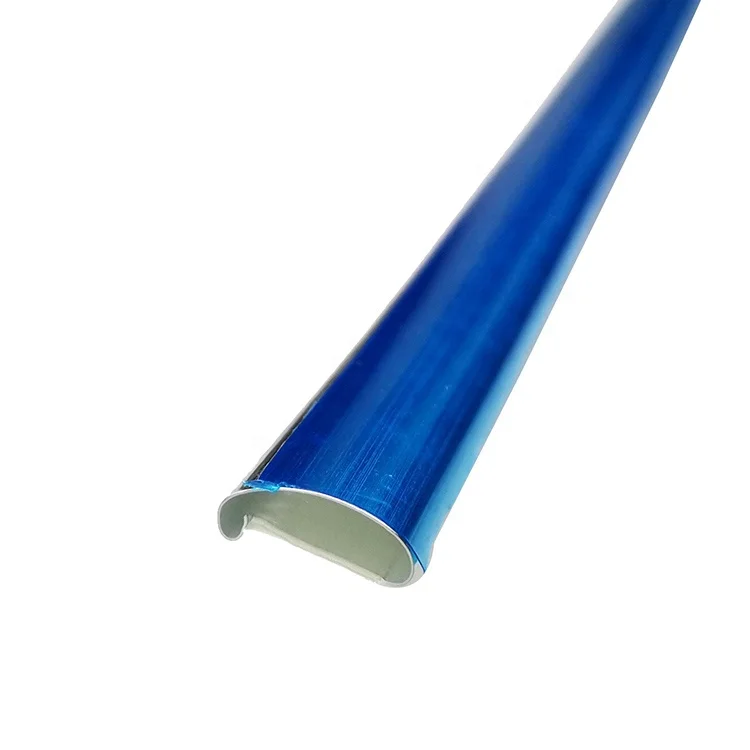

Shower glass frame seal strips are designed to fit around the edges of glass shower enclosures. Their primary function is to create a barrier that prevents water from leaking out of the enclosed shower space. Beyond their practical purpose, these strips contribute to the overall look of the shower area, providing a clean and finished appearance. Typically made from materials like PVC, silicone, or rubber, these strips are engineered to endure the moisture-rich environment of bathrooms while maintaining flexibility and resilience.

The Role of Seal Strips in Bathroom Design

The aesthetic impact of shower glass frame seal strips should not be underestimated. Customers increasingly prefer glass shower enclosures for their modern and sleek appearance. However, exposed edges can detract from this aesthetic. Seal strips not only conceal these edges but also provide a polished finish to the shower unit. Furthermore, they come in various colors and styles, allowing homeowners to choose options that best match their bathroom decor.

Aside from their beauty, seal strips play a vital role in safety. Shower areas can become slippery due to water accumulation, and seal strips help to keep water contained, minimizing the risk of slippery floors outside the shower. This is especially important in homes with children or elderly individuals who may be more prone to falls.

The Manufacturing Process of Seal Strips

shower glass frame seal strip factory

Producing high-quality shower glass frame seal strips involves several precise steps. Firstly, raw materials such as PVC, silicone, or rubber are selected based on the desired product characteristics. These materials are chosen for their durability, flexibility, and resistance to mold and mildew—key factors in shower environments.

Once the materials are chosen, the next step is the extrusion process. This involves heating and forcing the raw material through a die to create long strips of consistent shape and size. This method allows manufacturers to produce seal strips that fit various glass thicknesses and enclosure designs.

After extrusion, the strips are cooled and cut to the required lengths. Quality control checks are essential at this stage; manufacturers test for consistency in thickness, flexibility, and overall quality. Any defects are identified and addressed to ensure that every strip meets high industry standards.

Finally, the seal strips undergo surface treatments, including anti-fungal and anti-bacterial coatings, enhancing their longevity and hygiene. They are then packaged for distribution to retailers and installers, completing the manufacturing process.

Conclusion

Shower glass frame seal strips are small yet indispensable components of modern shower enclosures. They provide essential functions, including preventing water leakage, enhancing safety, and contributing to the overall aesthetic of the bathroom. The manufacturing process of these strips is intricate, focusing on material selection, precision extrusion, and quality control to ensure a reliable final product.

As homeowners continue to prioritize modern designs and functional features in their bathrooms, the importance of shower glass frame seal strips will only grow, making them a critical element for manufacturers and designers in the industry. Investing in high-quality seal strips can lead to long-lasting, beautiful, and safe shower environments that elevate the bathroom experience.

-

Premium Car Trim Strip - Top Car Moulding Trim Strip Exporters & 3 Car Moldings Manufacturers

NewsJul.08,2025

-

High-Quality Sponge Seal Solutions Leading Sponge Door Seal Manufacturer & Service

NewsJul.08,2025

-

U Shape Chrome Trim Strip Manufacturer & Exporter High-Quality Factory Products

NewsJul.07,2025

-

High-Quality LED Neon Light Supplier – Flexible & Color Changing Neon Strip Lights for Versatile Applications

NewsJul.07,2025

-

High-Quality White Transparent Silicone Strip Reliable Exporter & Factory Price

NewsJul.07,2025

-

Premium U Shape Chrome Trim Strip – Reliable Factory & Exporter for Automotive & Home Décor

NewsJul.06,2025