Side Door Seal Strip Manufacturer Providing High-Quality Solutions for Automotive and Industrial Needs

Aug . 01, 2024 04:21 Back to list

Side Door Seal Strip Manufacturer Providing High-Quality Solutions for Automotive and Industrial Needs

The Importance of Quality Side Door Seal Strips in Automotive Manufacturing

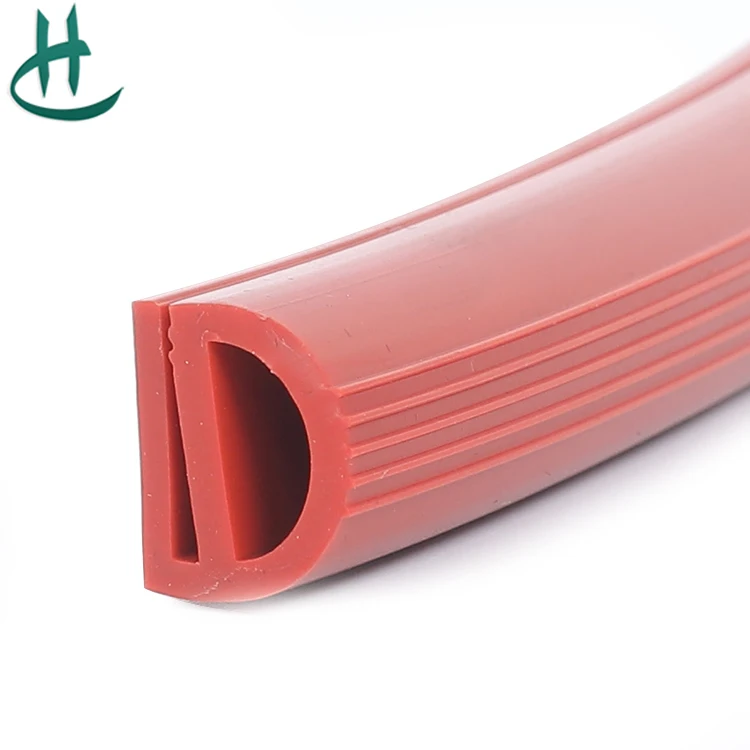

In the automotive industry, the seemingly simple components can significantly affect a vehicle's overall performance and user experience. One such crucial element is the side door seal strip. These components play an integral role in ensuring that vehicles are not only comfortable and quiet but also secure from external elements. Understanding the significance of high-quality side door seal strips, particularly in the context of factory production, can offer insights into automotive design and manufacturing efficiency.

Side door seal strips serve multiple functions. Primarily, they act as a barrier against water, dust, and wind, preventing these elements from entering the vehicle's cabin. A properly designed and installed seal strip ensures that users can enjoy a peaceful ride, devoid of the nagging sounds caused by wind noise or the intrusion of water during rainstorms. Beyond comfort, these strips also maintain the integrity of the vehicle’s interior, protecting it from potential damage caused by moisture and dirt accumulation.

In the competitive landscape of automotive manufacturing, factories must ensure that every component, including side door seal strips, meets a high standard of quality. This is where specialized factories come into play. A reliable side door seal strip factory focuses on sourcing premium raw materials, utilizing advanced technology for production, and adhering to stringent testing protocols. The materials used—often a blend of rubber and other durable compounds—must withstand harsh environmental conditions while maintaining their shape and function over time.

side door seal strip factory

The manufacturing process involves a range of techniques, including extrusion, molding, and sometimes even injection. These processes enable factories to create seal strips tailored specifically to a vehicle's design, ensuring a perfect fit. In recent years, technological advancements have led to the development of more sophisticated production lines that can produce high volumes of seal strips while maintaining quality and precision.

Moreover, a reputable side door seal strip factory will employ a robust quality assurance system. This system includes regular inspections and testing of raw materials and finished products to ensure they meet industry standards. The effectiveness of seal strips can be tested through various methods, such as water leakage tests and thermal cycling tests, which simulate real-world conditions. By investing in quality assurance, manufacturers can reduce warranty claims and enhance customer satisfaction—a crucial factor in the automotive market.

Sustainability is another increasingly important aspect of modern manufacturing. Factories committed to producing eco-friendly side door seal strips are leveraging recycled materials and adopting energy-efficient manufacturing processes. This not only appeals to environmentally conscious consumers but also aligns with global initiatives aimed at reducing carbon footprints in the automotive sector.

In conclusion, side door seal strips may be small components in the grand scheme of automotive design, but their importance cannot be overstated. They contribute to comfort, safety, and the overall durability of a vehicle. Factories specializing in the production of these seal strips play a vital role in the automotive supply chain, ensuring that manufacturers receive high-quality components that meet their specifications. As technology advances and consumer demands evolve, the future of side door seal strip manufacturing looks promising, with an emphasis not only on quality but also on sustainability and innovation. Thus, the quest for the perfect side door seal strip continues, driving improvements in both product performance and manufacturing processes in the automotive industry.

-

Replacement Filter Screen for Karcher SE3001 SE2001 Vacuum

NewsAug.04,2025

-

Karcher A2004 Vacuum Cartridge Filter Replacement - Durable & Efficient

NewsAug.03,2025

-

Karcher WD/MV HEPA Cartridge Filters | Dust Control Experts

NewsAug.02,2025

-

Top Window Seal Strip Adhesive Companies | Strong Weatherproofing

NewsAug.01,2025

-

Premium Oil Filter for Can-Am Outlander 2003-2017 420256188

NewsJul.31,2025

-

Hightech Injection LED Module size6414: Premium LED Lighting

NewsJul.31,2025