Bulk Suppliers of Durable Rubber Seal Strips for Export Business

Dec . 11, 2024 10:54 Back to list

Bulk Suppliers of Durable Rubber Seal Strips for Export Business

The Rise of Thick Rubber Seal Strip Exporters in Global Markets

In the ever-evolving landscape of international trade, the demand for robust and high-quality sealing solutions has been on the rise. One particular product that has seen significant growth is the thick rubber seal strip. Used across various industries, these seal strips play a crucial role in ensuring airtight and watertight seals in applications ranging from automotive engineering to construction.

Understanding Thick Rubber Seal Strips

Thick rubber seal strips are designed to provide a tight seal in various fittings and joints. Their unique properties make them suitable for a range of applications, including doors, windows, and machinery. The material, typically made from various types of rubber such as EPDM (ethylene propylene diene monomer), silicone, and neoprene, offers excellent resistance to weathering, chemicals, and temperature fluctuations. This makes them particularly important for industries that require long-lasting durability and reliability.

The Export Market Landscape

As demand for thick rubber seal strips continues to grow, exporters have capitalized on this trend by expanding their reach into international markets. Regions such as North America, Europe, and Asia-Pacific have seen an increase in imports of these sealing products, driven by robust construction activities and advancements in manufacturing processes. The globalization of supply chains has also facilitated easier access for exporters to target various markets that need dependable sealing solutions.

Exporters are increasingly focusing on quality standards and certifications, ensuring that their products meet the regulations set forth by different countries. This is crucial for establishing trust and reliability among consumers, particularly in sectors where safety and performance are paramount.

Factors Driving Demand

Several factors contribute to the increased demand for thick rubber seal strips in the export market

thick rubber seal strip exporters

2. Automotive Sector The automotive industry is one of the largest consumers of rubber seal strips, as they are essential for providing seals for doors, windows, and engine compartments.

3. Energy Efficiency With a growing emphasis on sustainability and energy efficiency, industries are looking for effective sealing solutions to minimize leaks and improve insulation, further driving the market for rubber seal strips.

4. Technological Advancements Innovations in manufacturing processes have improved the quality and performance of rubber seal strips, making them more appealing for various applications.

Challenges Faced by Exporters

Despite the booming demand, exporters of thick rubber seal strips face several challenges. These include fluctuating raw material prices, stringent regulatory requirements, and competition from domestic manufacturers. Moreover, shipping logistics and supply chain disruptions can pose significant hurdles for exporters aiming to maintain timely deliveries.

Conclusion

The export market for thick rubber seal strips continues to expand, fueled by industrial growth, technological advancements, and an increasing focus on energy efficiency. As exporters navigate the complexities of the global market, their ability to adapt and innovate will be key to their success. With the right strategies, thick rubber seal strip exporters can continue to thrive, meeting the ever-growing demand for reliable sealing solutions across various industries. Embracing quality, compliance, and customer satisfaction will ultimately set successful exporters apart in this competitive landscape.

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

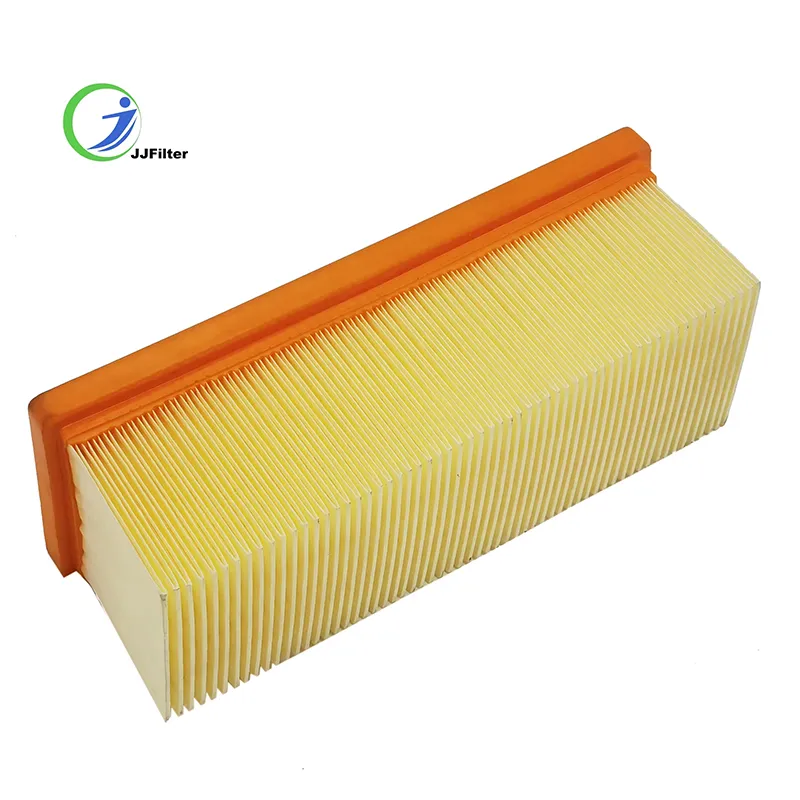

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025