truck door seal strip factory

Dec . 05, 2024 11:30 Back to list

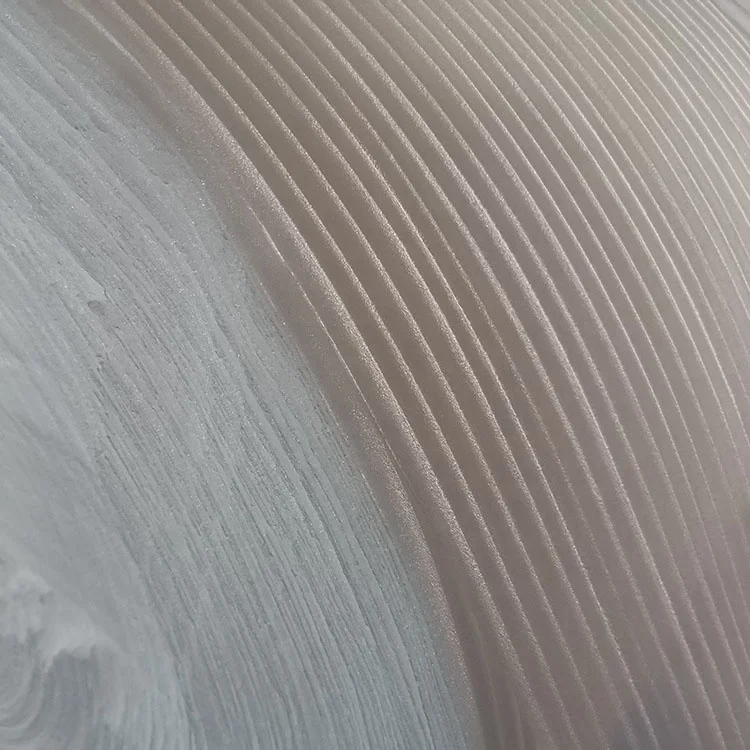

truck door seal strip factory

The Importance of Quality Truck Door Seal Strips Insights from the Factory

In the modern transportation industry, the integrity of cargo transportation is paramount. A critical yet often overlooked component that ensures the protection of goods during transit is the truck door seal strip. As an essential element designed to prevent dust, moisture, and unwanted contaminants from entering the cargo space, the quality of these seal strips directly influences the safety and security of hauled items. This article delves into the manufacturing processes of truck door seal strips, their significance, and the factors that determine their effectiveness.

Understanding Truck Door Seal Strips

Truck door seal strips, commonly made from rubber or synthetic materials, are designed to provide a tight seal around the edges of truck doors. Their primary function is to create a barrier that protects the contents from environmental elements such as water, dirt, and extreme temperatures. Additionally, they help to reduce noise and vibrations during transit, ensuring a smoother experience for the driver and guarding the integrity of sensitive cargo.

The manufacturing of these seal strips requires precision and adherence to quality standards. Factories that specialize in producing truck door seal strips employ advanced technologies and methodologies to ensure their products meet the stringent requirements of the automotive and transportation industries.

Manufacturing Process

1. Material Selection The first step in the manufacturing process is selecting the right materials. Rubber, thermoplastic elastomers, and other durable compounds are commonly used due to their resilience and ability to withstand varying weather conditions. The selection of materials also affects the seal's flexibility and compression set, which are crucial for maintaining effectiveness over time.

2. Molding and Extrusion After the materials are chosen, they are subjected to molding and extrusion processes. Molding involves shaping the rubber into the desired profile using heat and pressure, while extrusion allows for the continuous production of seal strips in specific lengths. These processes are critical in achieving the desired dimensions and uniformity of the seal strips.

3. Quality Control Once produced, the seal strips undergo rigorous quality control tests. These tests may include checks for flexibility, tensile strength, and resistance to wear and tear. Factories often utilize automated inspection systems to ensure that each batch meets quality standards. This step is vital, as any defect could compromise the effectiveness of the seal and potentially lead to product loss or damage.

truck door seal strip factory

4. Packaging and Distribution Finally, the approved seal strips are packaged for distribution. Proper packaging is essential to preserve the quality of the products during transportation to customers, be it large transportation companies or smaller distributors.

Significance of High-Quality Seal Strips

High-quality truck door seal strips offer several benefits

- Protection Against Elements A superior seal strip effectively prevents rain, snow, and dust from infiltrating the cargo area. This is particularly important for transporting food, electronics, and pharmaceuticals, where exposure to moisture and contaminants can lead to spoilage or damage.

- Cost Efficiency Investing in high-quality seal strips can reduce long-term costs. Lower quality seals may deteriorate faster, leading to increased maintenance needs or the risk of cargo damage, incurring additional expenses.

- Enhanced Driver Comfort Well-sealed truck doors also minimize external noise and vibrations, providing a more comfortable driving experience. This can contribute to increased focus and reduced driver fatigue during long hauls.

- Environmental Compliance With growing environmental standards, using effective door seal strips helps in maintaining vehicle efficiency by reducing the need for excessive heating or cooling within the cargo area, ultimately contributing to lower fuel consumption.

Conclusion

In summary, the significance of truck door seal strips cannot be overstated. As a factory that specializes in their production, it is imperative to prioritize quality at every manufacturing stage. From careful material selection to stringent quality control measures, the aim is to produce seal strips that not only meet but exceed industry standards. For businesses in the transportation sector, investing in high-quality truck door seal strips translates to higher efficiency, better cargo protection, and ultimately, enhanced profitability.

-

Top Window Seal Strip Adhesive Companies | Durable Weatherproof Seals

NewsJul.21,2025

-

Premium Car Trim Strip - Top Car Moulding Trim Strip Exporters & 3 Car Moldings Manufacturers

NewsJul.08,2025

-

High-Quality Sponge Seal Solutions Leading Sponge Door Seal Manufacturer & Service

NewsJul.08,2025

-

U Shape Chrome Trim Strip Manufacturer & Exporter High-Quality Factory Products

NewsJul.07,2025

-

High-Quality LED Neon Light Supplier – Flexible & Color Changing Neon Strip Lights for Versatile Applications

NewsJul.07,2025

-

High-Quality White Transparent Silicone Strip Reliable Exporter & Factory Price

NewsJul.07,2025