High-Quality Water Stop Rubber Seal Strip | Durable Water Barrier Solutions

Sep . 11, 2024 17:48 Back to list

High-Quality Water Stop Rubber Seal Strip | Durable Water Barrier Solutions

Exploring the Role of Water Stop Rubber Seal Strips in Construction A Focus on Factories

Waterproofing is a crucial aspect of construction and civil engineering, especially in projects involving water containment, such as dams, tunnels, and retaining walls. One of the key components in this process is the water stop rubber seal strip. Factories that specialize in producing these essential materials play a significant role in ensuring the longevity and efficiency of various structures.

What are Water Stop Rubber Seal Strips?

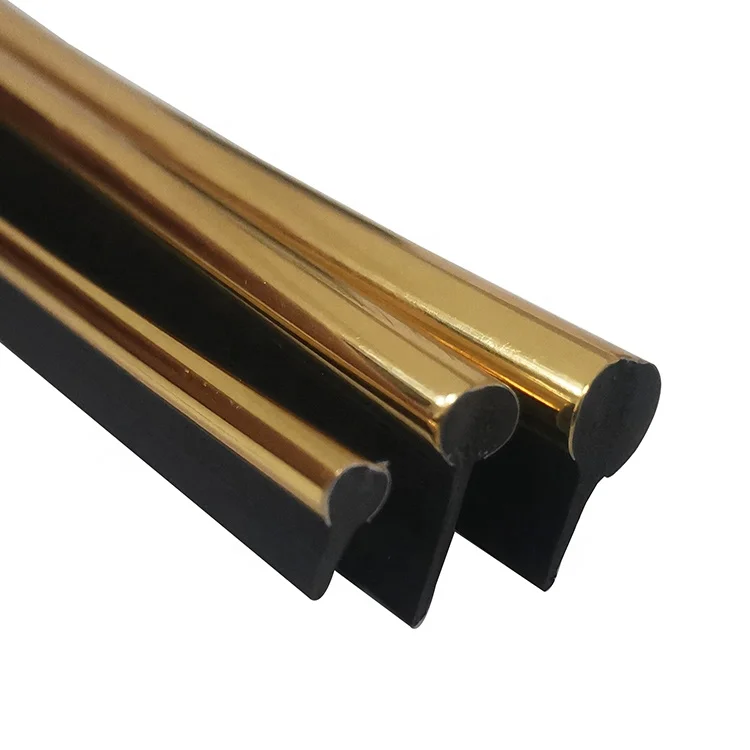

Water stop rubber seal strips are specialized materials designed to prevent water seepage in concrete joints. They act as a barrier, ensuring that water cannot pass through joints and cracks in structures. These strips are commonly made from high-quality rubber or thermoplastic elastomers that exhibit excellent flexibility, durability, and resistance to various environmental factors, including UV light, temperature changes, and chemical exposure.

The Manufacturing Process

The production of water stop rubber seal strips involves several critical steps. Factories typically use advanced manufacturing techniques and machinery to ensure precision and quality. The process begins with the selection of raw materials, which are tested for their physical and chemical properties. Following this, the rubber is compounded with additives that enhance its performance characteristics.

Once the rubber is prepared, it is shaped into strips using extrusion methods. This allows for uniformity in thickness and width, ensuring that the final product can fit seamlessly into construction joints. After extrusion, the strips undergo curing processes to improve their elasticity and strength. Finally, quality control inspections are conducted to verify that the strips meet industry standards and specifications.

water stop rubber seal strip factories

The Importance of Quality

The performance of water stop rubber seal strips is directly linked to their quality. High-quality seals provide optimal protection against water infiltration, minimizing the risk of structural damage, corroding steel reinforcements, and compromising the integrity of the concrete. Thus, factories focusing on quality assurance and utilizing premium materials are pivotal in the construction industry.

Applications in Construction

Water stop rubber seal strips are versatile and find applications in various areas of construction. They are primarily used in tunnels, basements, swimming pools, and any structure that requires water containment. The use of these seals allows engineers and builders to design structures that can withstand significant water pressure and prevent leakage, which is especially critical in areas prone to flooding.

Conclusion

Factories producing water stop rubber seal strips contribute significantly to the construction sector by providing essential materials that enhance structural integrity and longevity. As the demand for robust waterproofing solutions continues to grow, these factories are poised to innovate and improve their products, helping to meet the needs of an ever-evolving industry. Investing in high-quality waterproofing materials is not just a choice; it is a necessity for the sustainable development of infrastructure.

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025