waterproof door seal strip factories

Sep . 19, 2024 02:37 Back to list

waterproof door seal strip factories

The Importance of Waterproof Door Seal Strips An Overview of Factories and Manufacturing Process

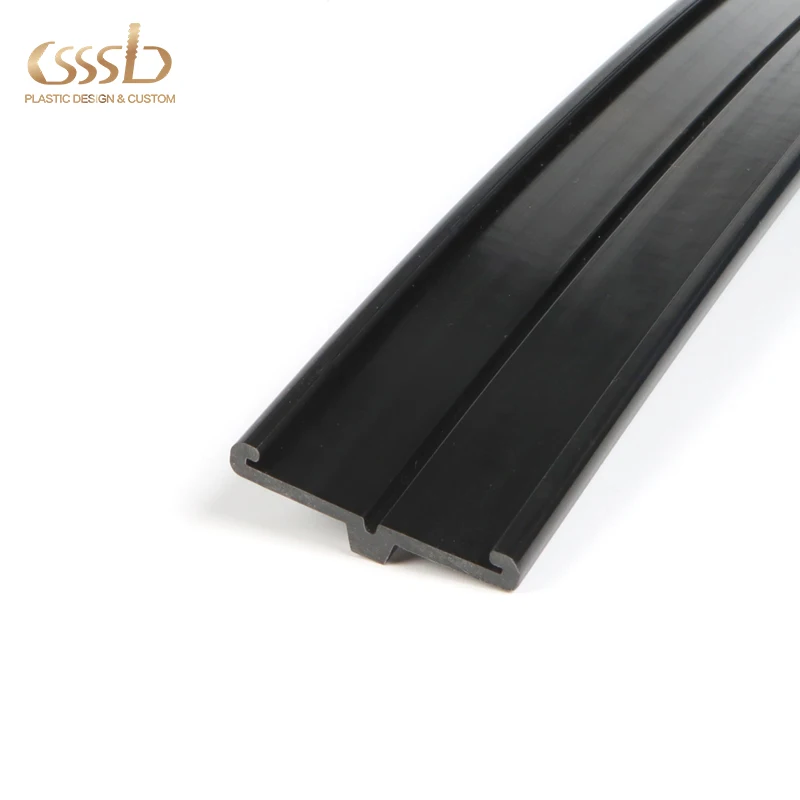

Waterproof door seal strips are essential components in ensuring that residential and commercial spaces remain protected from external elements such as water, dust, and pests. These seals reduce the risk of water damage caused by heavy rain or flooding, improve energy efficiency by preventing drafts, and contribute to a more comfortable indoor environment. Consequently, the demand for high-quality waterproof door seal strips has led to the establishment of numerous factories specializing in their production.

What are Waterproof Door Seal Strips?

Waterproof door seal strips are flexible strips made from various materials, including rubber, silicone, and foam. These materials are designed to create a tight seal around doors, effectively blocking water and air from entering. The effectiveness of these seals largely depends on their design and the material used. High-quality seal strips often come with features such as UV resistance, temperature stability, and durability, making them suitable for various conditions and environments.

The Manufacturing Process

The production of waterproof door seal strips generally involves several key stages

1. Material Selection Factories carefully choose materials that offer waterproof qualities and durability. Common materials include EPDM rubber, which is resistant to weathering, and silicone, known for its high flexibility and temperature resistance.

2. Extrusion The selected materials are melted and passed through an extruder. This machine shapes the material into long strips of desired dimensions. During this phase, manufacturers can customize the profile of the seal strips to ensure they fit snugly against doors.

waterproof door seal strip factories

3. Curing and Finishing After extrusion, the strips undergo a curing process to enhance their properties. This process involves heating the material, which allows it to retain its shape and improve its waterproof capabilities. Factories may also add finishes or coatings that provide additional benefits, such as anti-fungal properties.

4. Quality Control Before the seal strips are packaged and shipped, they undergo rigorous quality control testing. This includes checking for elasticity, water resistance, and overall durability. Factories often have set benchmarks to ensure that their products meet industry standards.

5. Packaging Finally, the waterproof door seal strips are cut to size and packaged for distribution. Many factories focus on sustainable packaging options to reduce their environmental impact.

Choosing the Right Factory

When looking for manufacturers of waterproof door seal strips, several factors should be considered

- Quality of Materials Ensure that the manufacturing facility uses high-grade materials that meet international standards. - Customization Options Depending on your needs, it may be beneficial to find a factory that allows for customization in terms of size, shape, and color. - Certifications Check if the factory has relevant certifications for quality control, such as ISO or similar standards. - Production Capacity If you are looking for bulk orders, ensure that the factory can meet your demand in a timely manner.

Conclusion

Waterproof door seal strips play a crucial role in protecting properties from unwanted water and air infiltration. As the demand for these products rises, the factories that manufacture them are continually evolving to meet customer needs with high-quality and innovative solutions. Whether for residential or commercial use, investing in durable and effective waterproof door seal strips from reputable factories can lead to long-term benefits and savings in maintenance and energy costs.

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025