window rubber sealing strip factories

Nov . 17, 2024 13:17 Back to list

window rubber sealing strip factories

Exploring Window Rubber Sealing Strip Factories Ensuring Quality and Durability

Window rubber sealing strips play a pivotal role in the construction and maintenance of windows. Their primary function is to provide effective sealing against weather elements, noise, and dust, thereby enhancing energy efficiency and improving the overall comfort of indoor spaces. With the rising demand for high-quality window sealing solutions, numerous factories dedicated to the production of rubber sealing strips have emerged. This article delves into the importance of window rubber sealing strip factories, the manufacturing process, and the significance of quality assurance in the industry.

The Importance of Window Rubber Sealing Strips

Window sealing strips are essential to both residential and commercial buildings. They serve as a barrier against air leaks, which can lead to significant energy loss. In regions with extreme weather conditions, the absence of effective sealing can result in high heating and cooling costs. Moreover, sealing strips contribute to noise reduction, leading to a more peaceful indoor environment. This has become increasingly relevant in urban areas, where external noise can be disruptive to daily life.

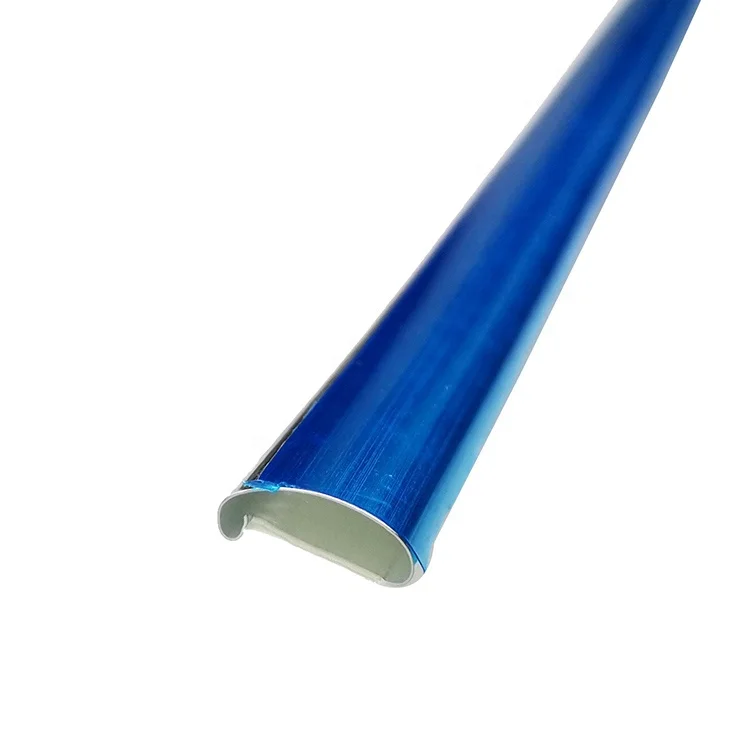

The materials used for these sealing strips are typically rubber, silicone, or EPDM (ethylene propylene diene monomer). Each material has its unique properties, such as flexibility, durability, and resistance to various environmental factors. The choice of material ultimately affects the performance and longevity of the sealing strips, underscoring the importance of high-quality manufacturing processes.

The Manufacturing Process

The manufacturing of window rubber sealing strips involves several critical steps to ensure product integrity and performance. The process begins with the selection of raw materials. Manufacturers must source high-quality rubber compounds that meet industry standards and comply with relevant regulations. The choice of materials can significantly influence the sealing strip's resistance to UV rays, ozone, and temperature fluctuations.

Once the raw materials are procured, the production process typically involves the following stages

1. Compounding In this stage, the raw rubber is mixed with various additives, such as colorants, stabilizers, and curing agents. This step is crucial as it determines the sealing strip's physical properties, including flexibility, hardness, and aging resistance.

2. Molding The compounded rubber is then shaped into strips using a molding process. This can involve extrusion or compression molding, depending on the desired shape and dimensions.

window rubber sealing strip factories

3. Curing After molding, the rubber strips undergo a curing process, which involves heating them to a specific temperature. This step is essential for cross-linking the rubber molecules, imparting strength and durability to the final product.

4. Quality Control Post-curing, the sealing strips are subjected to rigorous quality control tests. Manufacturers must ensure that each batch meets predetermined specifications for dimensions, softness, tensile strength, and resistance to environmental factors.

5. Packaging and Distribution Finally, the approved products are packaged appropriately and prepared for distribution. Manufacturers often provide various sizes and lengths to meet diverse client needs.

Quality Assurance and Its Significance

In the window rubber sealing strip industry, quality assurance is paramount. High-quality sealing strips not only ensure optimal performance but also instill confidence in manufacturers and builders who rely on these products. Poor-quality strips can lead to premature failures, resulting in costly repairs and diminished energy efficiency.

Quality assurance involves stringent testing protocols and compliance with international standards, such as ISO certifications. Factories are often required to maintain quality assurance systems that encompass every stage of production, from raw material sourcing to final inspection of the products.

Moreover, advancements in technology, such as automation and computer-aided design, have significantly enhanced the manufacturing process. These technologies enable factories to achieve consistent quality and precision in their products, which ultimately benefits consumers.

Conclusion

In conclusion, window rubber sealing strip factories play a crucial role in the building industry by providing essential products that enhance energy efficiency, comfort, and durability. The meticulous manufacturing process, focused on utilizing high-quality materials and adhering to stringent quality control measures, ensures that these sealing strips perform effectively in various environments. As the demand for building insulation and energy efficiency continues to rise, the significance of rubber sealing strips and their manufacturers will only grow, emphasizing the importance of innovation and quality in this vital sector.

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025