OEM DS Brown Strip Seal for Enhanced Durability and Performance in Automotive Applications

jul . 30, 2024 13:38 Back to list

OEM DS Brown Strip Seal for Enhanced Durability and Performance in Automotive Applications

Understanding OEM DS Brown Strip Seal A Comprehensive Overview

In the world of automotive and industrial components, seals play a crucial role in maintaining the integrity and performance of various systems. One such component that has gained popularity in recent years is the OEM DS brown strip seal. This article aims to provide an in-depth understanding of what OEM DS brown strip seals are, their applications, benefits, and why they are essential for various industries.

What is an OEM DS Brown Strip Seal?

The term OEM stands for Original Equipment Manufacturer, which indicates that the part is produced by the company that makes the original product. DS, in this context, may refer to a design specification or a particular series of products. Brown strip seals, specifically, are flexible sealing components utilized to ensure a tight fit between two surfaces, preventing the ingress of dirt, water, and other contaminants that can lead to equipment failure.

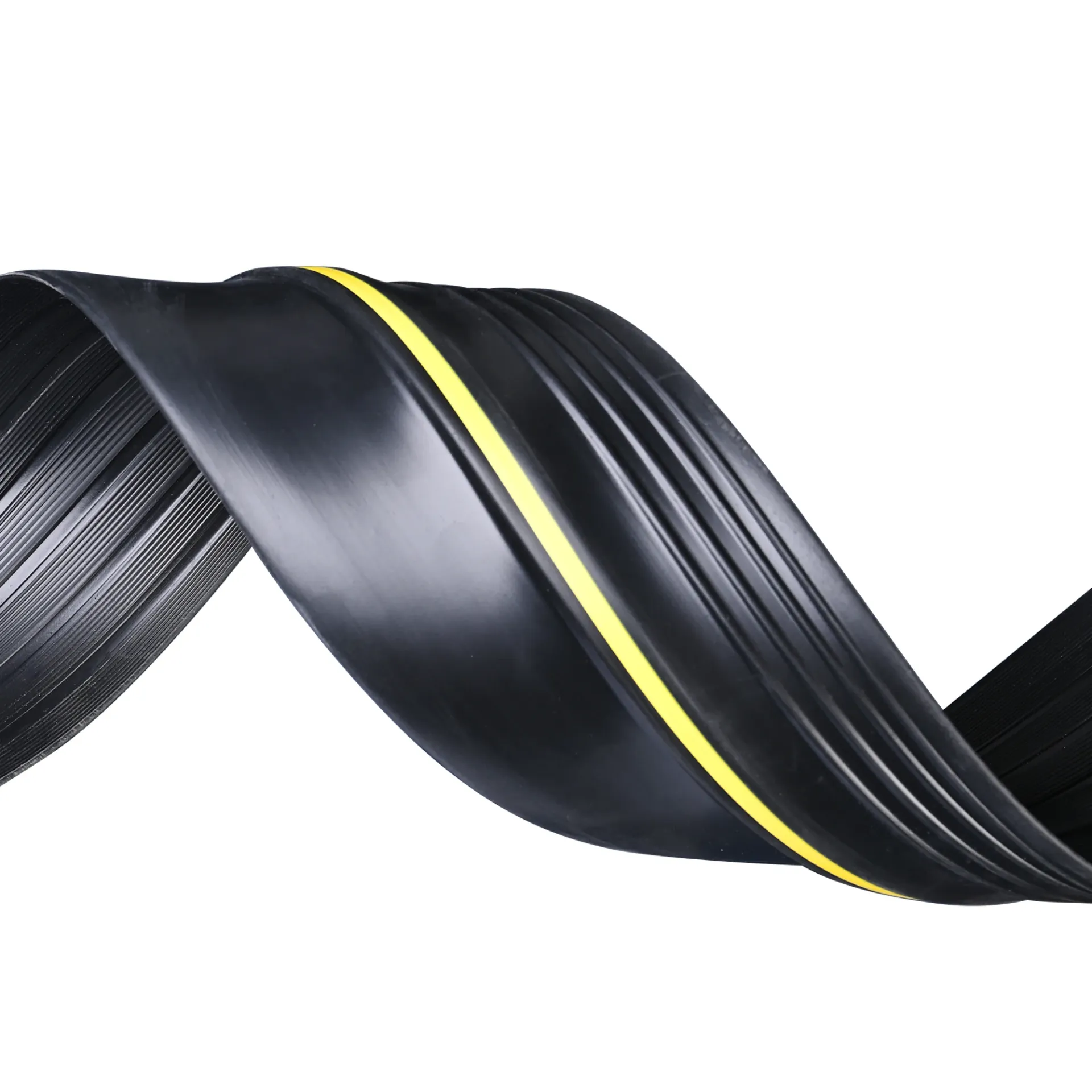

Typically made from high-quality rubber or silicone materials, OEM DS brown strip seals are designed to withstand various environmental conditions, making them suitable for both automotive and industrial applications. Their brown color often indicates a specific formulation that provides enhanced durability and resistance to wear.

Applications of OEM DS Brown Strip Seals

OEM DS brown strip seals are versatile components found in numerous applications. In the automotive industry, they are commonly used in doors, windows, and trunk lids, providing noise reduction and weatherproofing. They are essential in ensuring that vehicles remain comfortable and free of water ingress during inclement weather.

In industrial settings, these seals are used in machinery, equipment enclosures, and HVAC systems. Their ability to provide an effective barrier against dust and moisture protects sensitive internal components, prolonging the equipment's lifespan and reducing maintenance costs.

oem ds brown strip seal

Benefits of Using OEM DS Brown Strip Seals

1. Enhanced Durability One of the primary advantages of OEM DS brown strip seals is their robustness. Designed to endure harsh conditions, they can withstand exposure to UV rays, extreme temperatures, and various chemicals.

2. Improved Performance By ensuring a tight seal, these components enhance the overall performance of the system they are integrated into. This prevents the escape of fluids and gases, contributing to the efficiency of engines and machinery.

3. Cost-Effectiveness While opting for OEM parts can be more expensive than aftermarket alternatives, the long-term benefits often outweigh the initial costs. The reliability of OEM DS brown strip seals leads to reduced maintenance requirements and lower failure rates.

4. Custom Fit and Compatibility Being an OEM part, the DS brown strip seal is designed to fit perfectly with specific models, ensuring optimal functionality. This custom fit minimizes the risk of seal deformation or failure.

Conclusion

In conclusion, OEM DS brown strip seals are critical components in both the automotive and industrial sectors. Their unique design and high-quality materials make them effective at providing a reliable barrier against contaminants. By choosing OEM parts, businesses and consumers alike can ensure they are investing in durability, performance, and cost-effectiveness. As industries continue to evolve, the importance of such components remains steadfast, highlighting the need for reliable seals like the OEM DS brown strip seal in maintaining operational efficiency and product longevity.

-

High-Performance Oil Filter H F123 Kawasaki KL250-KLX650 | Engine Protection

NewsAug.05,2025

-

Replacement Filter Screen for Karcher SE3001 SE2001 Vacuum

NewsAug.04,2025

-

Karcher A2004 Vacuum Cartridge Filter Replacement - Durable & Efficient

NewsAug.03,2025

-

Karcher WD/MV HEPA Cartridge Filters | Dust Control Experts

NewsAug.02,2025

-

Top Window Seal Strip Adhesive Companies | Strong Weatherproofing

NewsAug.01,2025

-

Premium Oil Filter for Can-Am Outlander 2003-2017 420256188

NewsJul.31,2025