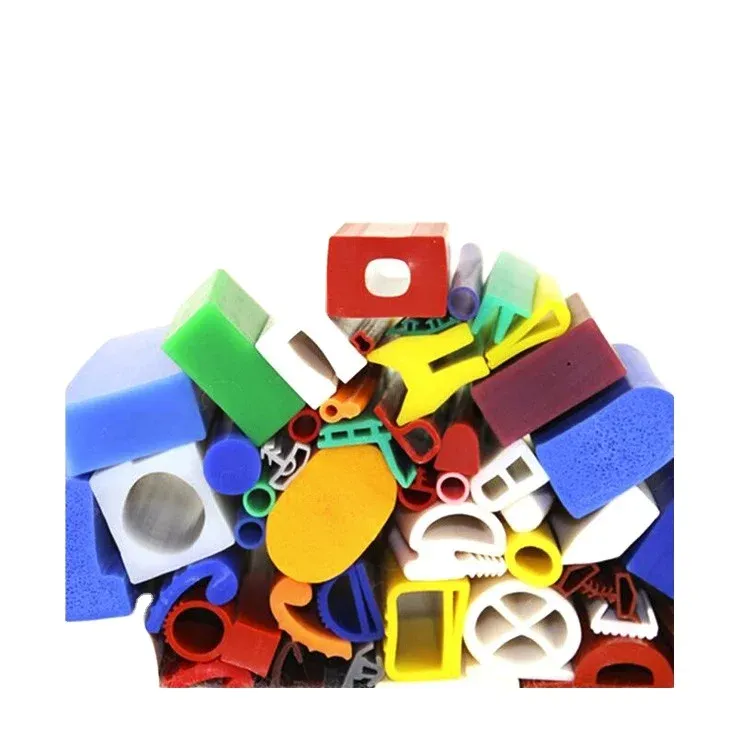

ce cetification silicone rubber plastic strip

Feb . 19, 2025 03:06 Back to list

ce cetification silicone rubber plastic strip

Silicone rubber plastic strips certified by CE standards represent a vital evolution in material science, particularly in industries ranging from construction to medical devices. The blend of silicone's flexibility with the durability of plastic forms a versatile product with countless applications. The process behind the certification, however, requires a nuanced understanding of both material properties and European regulatory standards.

One critical area in achieving CE certification is ensuring the safety of the silicone rubber plastic strips. Particularly in sectors subject to stringent regulations like healthcare, manufacturers must demonstrate that their products do not pose risks to user safety. This involves detailed documentation of potential risks, mitigation strategies, and comprehensive testing to showcase compliance with safety standards. Furthermore, manufacturers need to keep detailed technical documentation to support their compliance claims. This documentation typically includes design and manufacturing process descriptions, risk assessments, and test results. For organizations aiming at maintaining their certification, it involves continuous market surveillance and product testing to ensure ongoing compliance, highlighting the manufacturer's long-term commitment to quality. In the competitive landscape of silicone rubber plastic strips, a CE mark can significantly enhance a product's marketability. It assures potential users that the product aligns with high safety and environmental standards, thereby fostering confidence in the product’s integrity. Companies armed with this certification can not only bolster their market position within the European Union but also gain a competitive edge in markets where CE certification is deemed synonymous with quality and safety. Manufacturers are advised to engage in rigorous employee training and quality assurance processes to uphold the certification's standards. By investing in these areas, companies ensure that every aspect of production—from design and raw material selection to final inspection—is administered with maximum quality control. This investment is pivotal in sustaining the product's quality and the company's reputation. In conclusion, the path to achieving and maintaining CE certification for silicone rubber plastic strips reflects a broader commitment to excellence and safety. The processes involved in certification authenticate the expertise and trustworthiness of a manufacturer, opening doors to expansive markets and instilling confidence across the supply chain. Such diligence not only benefits the direct consumers of the product but ensures a safe and innovative future in material applications.

One critical area in achieving CE certification is ensuring the safety of the silicone rubber plastic strips. Particularly in sectors subject to stringent regulations like healthcare, manufacturers must demonstrate that their products do not pose risks to user safety. This involves detailed documentation of potential risks, mitigation strategies, and comprehensive testing to showcase compliance with safety standards. Furthermore, manufacturers need to keep detailed technical documentation to support their compliance claims. This documentation typically includes design and manufacturing process descriptions, risk assessments, and test results. For organizations aiming at maintaining their certification, it involves continuous market surveillance and product testing to ensure ongoing compliance, highlighting the manufacturer's long-term commitment to quality. In the competitive landscape of silicone rubber plastic strips, a CE mark can significantly enhance a product's marketability. It assures potential users that the product aligns with high safety and environmental standards, thereby fostering confidence in the product’s integrity. Companies armed with this certification can not only bolster their market position within the European Union but also gain a competitive edge in markets where CE certification is deemed synonymous with quality and safety. Manufacturers are advised to engage in rigorous employee training and quality assurance processes to uphold the certification's standards. By investing in these areas, companies ensure that every aspect of production—from design and raw material selection to final inspection—is administered with maximum quality control. This investment is pivotal in sustaining the product's quality and the company's reputation. In conclusion, the path to achieving and maintaining CE certification for silicone rubber plastic strips reflects a broader commitment to excellence and safety. The processes involved in certification authenticate the expertise and trustworthiness of a manufacturer, opening doors to expansive markets and instilling confidence across the supply chain. Such diligence not only benefits the direct consumers of the product but ensures a safe and innovative future in material applications.

Latest news

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025