led plastic pc extrusion diffuser profile supplier

Dec . 25, 2024 07:11 Back to list

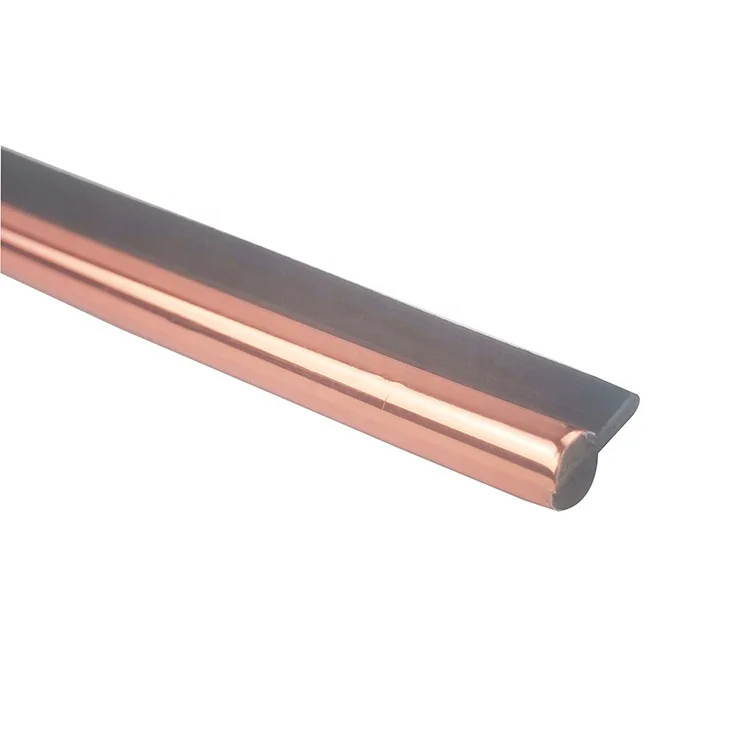

led plastic pc extrusion diffuser profile supplier

LED Plastic PC Extrusion Diffuser Profile Supplier A Comprehensive Guide

In today's rapidly evolving lighting industry, the demand for high-quality LED solutions continues to grow. Among these solutions, LED plastic PC (polycarbonate) extrusion diffuser profiles play a crucial role in enhancing the performance and aesthetics of LED lighting fixtures. As a supplier of such profiles, understanding the significance, manufacturing process, and advantages of these diffusers is essential for businesses looking to provide top-notch lighting solutions.

What is an LED Plastic PC Extrusion Diffuser Profile?

An LED plastic PC extrusion diffuser profile is a specially designed component made from polycarbonate material that is utilized in LED lighting systems. Its primary purpose is to distribute light uniformly and eliminate glare, thereby improving the quality of light emitted by LED sources. The extrusion process allows manufacturers to create profiles in various shapes and sizes, making them versatile for different applications.

The Manufacturing Process

The manufacturing of plastic PC extrusion diffuser profiles involves several key steps

1. Material Selection The first step is to choose high-quality polycarbonate resin known for its excellent transparency, impact resistance, and UV stability. This ensures that the diffuser not only performs well but also has a long lifespan.

2. Extrusion The chosen polycarbonate resin is melted and forced through a die to form a continuous profile. This die can be customized to create specific shapes and sizes that cater to different lighting designs.

3. Cooling and Cutting After extrusion, the profiles are cooled and then cut to the required lengths. Precise cutting is crucial for ensuring that the finished products fit seamlessly into various lighting fixtures.

5. Quality Control Before being supplied to customers, the finished products undergo rigorous quality control checks to ensure they meet industry standards and customer specifications.

Benefits of Using LED Plastic PC Extrusion Diffuser Profiles

led plastic pc extrusion diffuser profile supplier

Several advantages make LED plastic PC extrusion diffuser profiles a preferred choice for many lighting applications

1. Light Diffusion One of the primary benefits of using PC diffusers is their ability to disperse light evenly. This helps in achieving a soft lighting effect that enhances visual comfort and reduces hotspots.

2. Durability Polycarbonate is known for its strength and resilience. It can withstand impacts and is less likely to shatter compared to glass, making it an ideal choice for various environments.

3. UV Resistance High-quality PC materials are resistant to yellowing and UV degradation, ensuring that the diffuser maintains its clarity and performance over time, even when exposed to sunlight.

4. Customization Manufacturers can create custom profiles to meet specific design requirements. This flexibility caters to a wide range of applications, from commercial to residential lighting.

5. Ease of Installation The lightweight nature of PC diffusers makes them easy to handle and install, which reduces labor costs and installation time.

Applications of LED Plastic PC Extrusion Diffuser Profiles

LED plastic PC extrusion diffuser profiles are used in a multitude of applications, including

- Commercial Lighting Used in office buildings, retail environments, and malls to provide ambient lighting. - Architectural Lighting Enhances the aesthetic appeal of buildings and structures. - Residential Lighting Ideal for homes, providing both functional and decorative lighting. - Industrial Lighting Suited for factories and warehouses where durability and performance are essential.

Conclusion

As the lighting industry continues to innovate, LED plastic PC extrusion diffuser profiles stand out for their versatility and effectiveness. Suppliers looking to meet the growing demand for quality lighting solutions should consider these profiles as essential components of their offerings. By understanding their benefits, manufacturing processes, and applications, suppliers can better serve their customers and contribute to the advancement of LED lighting technology. Whether for commercial, residential, or industrial purposes, LED plastic PC extrusion diffuser profiles offer an excellent solution for achieving optimal lighting performance.

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025