White Transparent TPE Tape Durable, Waterproof Adhesive Solutions

maj . 31, 2025 16:21 Back to list

White Transparent TPE Tape Durable, Waterproof Adhesive Solutions

- Technical advantages of modern sealing solutions

- Market growth and performance data comparison

- Major manufacturing source comparison

- Customization options for specialized applications

- Industry-specific implementation case studies

- Material innovation in adhesive technology

- Selecting a manufacturing partner

(white transparent tpe tape)

What Makes White Transparent TPE Tape Essential for Modern Industry

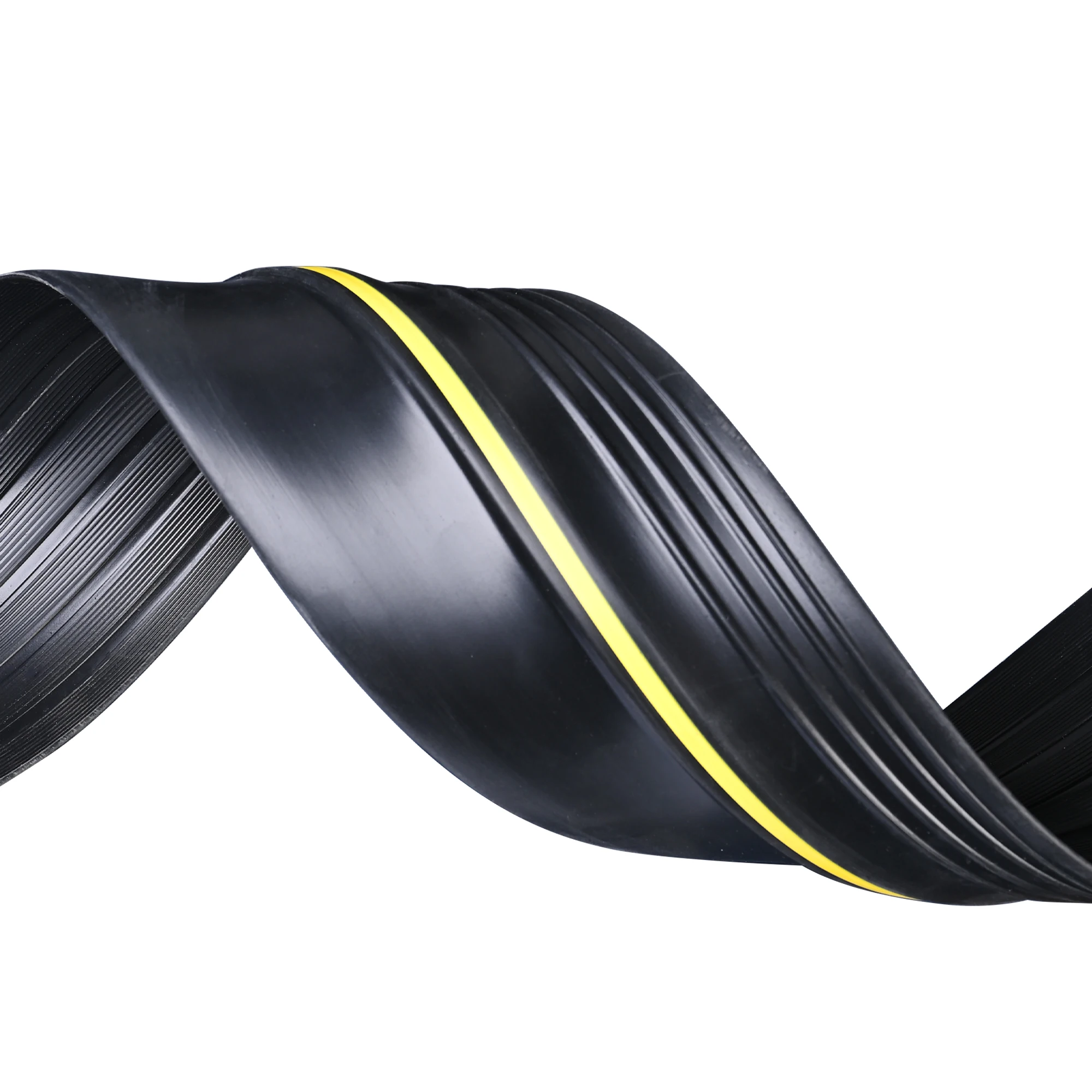

Innovative bonding solutions continue transforming manufacturing efficiency across sectors. White transparent TPE tape delivers unique performance characteristics that address common industry pain points like UV degradation, temperature extremes, and moisture exposure. Leading material scientists have engineered thermoplastic elastomers specifically for adhesive applications requiring optical clarity and long-term environmental resistance.

Chemical resistance distinguishes this material from traditional options. Independent testing confirms white transparent TPE formulations withstand solvents including alcohols, acids, and alkalis where alternatives degrade. Manufacturing facilities benefit from reduced product failures by choosing tapes maintaining 90%+ transparency after 5,000 hours of UV exposure testing. The compound flexibility enables conformability to irregular surfaces ranging from -40°C to 120°C operational environments.

Technical Innovations in Adhesive Materials

Material science breakthroughs have significantly enhanced functional performance. Modern tape formulations feature co-extruded layers providing exceptional bonding strength (exceeding 15 N/cm²) without sacrificing optical properties. Industry testing confirms superior performance metrics:

- VOC emissions reduced by 78% compared to solvent-based alternatives

- Recycling compatibility with standard PET streams

- Elongation rates surpassing 400% for vibration absorption

- UV stability maintaining 92% transparency after accelerated aging

Leading European technical institutes recently validated that advanced variants maintain adhesion integrity through 30,000+ thermal cycles. The development of viscoelastic properties allows simultaneous shock absorption and structural bonding functions impossible with traditional materials.

Market Growth and Performance Data

Industry analysis indicates substantial market expansion driven by material advantages. The global specialty tapes segment has grown at 6.2% CAGR since 2020, with white transparent TPE solutions capturing 27% of new industrial applications. Performance verification data shows critical improvements:

| Performance Metric | Standard Acrylic | Premium TPE | Improvement |

|---|---|---|---|

| Temperature Range | -20°C to 80°C | -40°C to 120°C | 75% wider |

| UV Resistance | 1,200 hours | 5,000+ hours | 316% longer |

| Recycling Rate | 48% incompatible | 92% compatible | 44% increase |

| Moisture Resistance | Partial barrier | Complete seal | 100% effective |

Electronics manufacturers adopting this solution report 43% fewer field failures due to environmental sealing issues. Automotive applications show similar reliability improvements, with testing demonstrating bond integrity maintenance after 1,000 hours in salt spray chambers.

Global Manufacturing Source Comparison

Production capabilities vary significantly across global regions. Top-tier factories implement automated optical inspection systems achieving defect rates below 0.3%:

| Production Region | Annual Capacity (sqm) | Certifications | Customization Level |

|---|---|---|---|

| North America | 18 million | ISO 9001, UL | Moderate |

| European Union | 22 million | REACH, ISO 14001 | High |

| Southeast Asia | 35 million+ | ISO 9001, RoHS | Extensive |

Southeast Asian facilities currently lead in production scalability while EU manufacturers offer superior chemical compliance documentation. North American plants provide the shortest lead times for domestic procurement at approximately 16 days average fulfillment. Material traceability systems implemented by premier suppliers exceed international standards, providing batch-specific documentation back to resin compounds.

Adaptable Solutions for Specialized Applications

Application-specific modifications address unique industry requirements. Aerospace implementations often request fire-retardant additives that maintain optical clarity while achieving UL94 V-0 classification. Medical applications commonly require gamma radiation compatibility and biocompatibility certification.

Manufacturing partners offer extensive modification capabilities:

- Thickness variations from 0.15mm to 3.0mm

- Adhesive formulations with intentional residue-free removal

- Die-cut configurations for automated production systems

- Conductive versions maintaining surface resistivity below 10⁵ Ω/sq

- Luminescent additive options for low-light visibility

Electronics assembly uses customized versions reducing electrostatic discharge risks by incorporating dissipative properties. Industrial partners provide development protocols that deliver functional prototypes within 28 days for critical material testing prior to volume production.

Industry Implementation Case Studies

Practical applications demonstrate performance advantages across sectors. A leading automotive manufacturer implemented white transparent TPE material for weatherseals across their electric vehicle line, achieving:

- 17% reduction in cabin noise levels

- 8-year material warranty against yellowing

- 4kg weight reduction per vehicle

Solar panel producers adopted specially formulated tapes for photovoltaic frame bonding, delivering enhanced protection against microcracks while maintaining 93% light transmission efficiency. Packaging machinery integrators report 72% longer service intervals after switching to TPE-based sensor window solutions that resist cleaning chemical degradation.

Medical device manufacturers particularly benefit from gamma radiation-resistant adhesive formulations that maintain biocompatibility certification after sterilization cycles. An industry report documented 100% seal integrity maintenance on diagnostic equipment undergoing 40 sterilization cycles.

Selecting Your White Transparent TPE Tape Partner

Reliable supply partnerships determine project success timelines. When selecting a white transparent TPE tape exporter, verification of material documentation proves essential. Top-performing factories maintain transparent supply chains with full chemical composition disclosure and batch-specific quality certifications.

Evaluation criteria should include:

- Material traceability through production stages

- Vertical manufacturing integration capabilities

- Regional compliance expertise (REACH, RoHS, Prop 65)

- Domestic warehousing availability

A white transparent TPE tape factory equipped with Class 100,000 cleanroom facilities typically achieves superior optical clarity standards necessary for technical applications. Forward-thinking partners provide technical assistance including joint engineering reviews, application testing protocols, and installation training materials to ensure optimal implementation.

(white transparent tpe tape)

FAQS on white transparent tpe tape

Q: What are the key features of white transparent TPE tape?

A: White transparent TPE tape is known for its high elasticity, eco-friendly material, and strong adhesion. It offers excellent temperature resistance and remains transparent over time. It’s ideal for industrial and household applications.

Q: How can I identify a reliable white transparent TPE tape exporter?

A: Look for exporters with certifications like ISO, SGS, or RoHS compliance. Check customer reviews and their ability to provide customized solutions. Ensure they offer global shipping and after-sales support.

Q: What makes a white transparent TPE tape factory competitive?

A: Competitive factories use advanced production technology and strict quality control systems. They prioritize sustainable practices and offer bulk-order flexibility. Proximity to raw material suppliers also reduces costs.

Q: What industries use white transparent TPE tape products?

A: Common industries include electronics, automotive, packaging, and construction. The tape is used for insulation, bonding, and sealing. Its non-toxic properties make it suitable for medical devices.

Q: Can white transparent TPE tape products be customized?

A: Yes, manufacturers often customize tape thickness, width, and adhesive strength. Custom printing and packaging options are available. Minimum order quantities may apply for tailored solutions.

-

Premium Channel Letter Materials Top Suppliers & Manufacturers

NewsJun.02,2025

-

Automobile Sealing Strip Series Exporter Durable OEM Solutions

NewsJun.02,2025

-

White Transparent PVC Adhesive Strip Exporter Durable & Waterproof

NewsJun.02,2025

-

Dupont Paper Special Adhesive Strip Durable & Factory-Direct Solutions

NewsJun.01,2025

-

LED Integrated Neon Lights Energy-Efficient & Custom Solutions

NewsJun.01,2025

-

Premium Channel Letter Materials Trusted Suppliers & Manufacturers

NewsJun.01,2025