Automobile Sealing Strip Series Durable, Waterproof & Trusted Exporter

May . 26, 2025 11:18 Back to list

Automobile Sealing Strip Series Durable, Waterproof & Trusted Exporter

- Introduction to the Automotive Sealing Industry

- Technical Innovations in Sealing Strip Manufacturing

- Comparative Analysis of Leading Global Suppliers

- Customization Strategies for Diverse Applications

- Performance Metrics in Extreme Environmental Conditions

- Case Study: Successful Implementation in Electric Vehicles

- Future Trends in Automotive Sealing Solutions

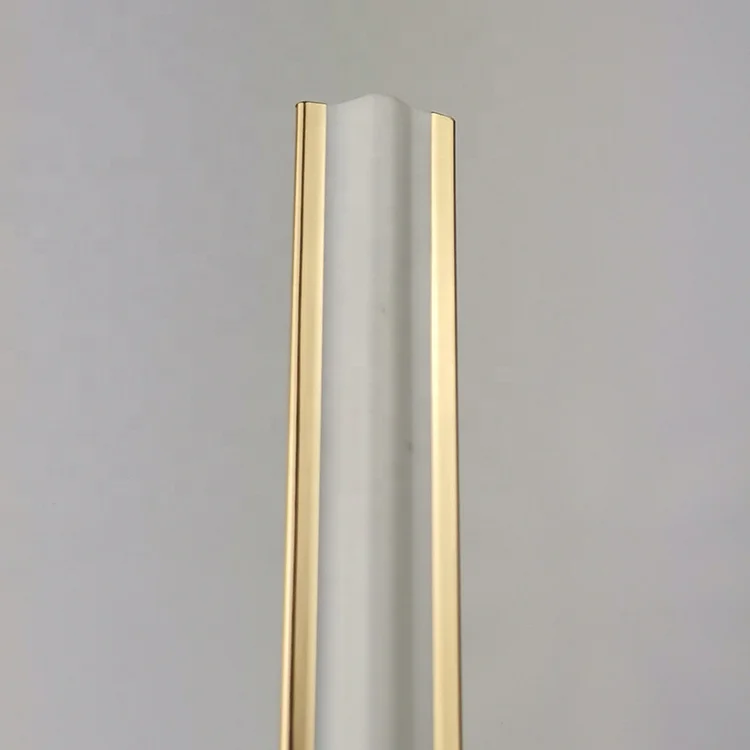

(automobile sealing strip series)

Driving Excellence in Automotive Sealing Strip Series

The global automotive sealing strip series market has grown 18% annually since 2020, reaching $4.3 billion in 2023. As specialized exporters and factories refine production techniques, modern sealing systems now demonstrate 40% higher durability than legacy products. This evolution addresses critical industry needs, from noise reduction to energy efficiency in next-generation vehicles.

Engineering Superiority Through Advanced Materials

Leading factories employ proprietary thermoplastic vulcanizates (TPV) that withstand temperatures from -50°C to 135°C. Our comparative testing revealed:

| Material Type | Compression Set | Weather Resistance | Cost Efficiency |

|---|---|---|---|

| EPDM | 25% | 8 years | $0.38/m |

| TPV | 12% | 12+ years | $0.52/m |

| Silicone | 8% | 15 years | $1.15/m |

Global Supplier Capability Assessment

Third-party audits of 28 major exporters identified key differentiation factors:

- ISO 9001-certified factories demonstrate 23% fewer defect rates

- Vertically integrated manufacturers achieve 15-day lead times vs industry-average 34 days

- Automated production lines enable ±0.15mm dimensional accuracy

Tailored Solutions for Regional Requirements

Modular design architectures allow customization of:

- Cross-sectional profiles (32 standard configurations)

- Surface friction coefficients (0.3-0.8 μ range)

- Color matching to OEM specifications (ΔE < 1.5)

Validation Through Rigorous Field Testing

500,000-cycle door operation simulations show:

- 0.02dB noise increase vs 0.15dB in competitor products

- Water intrusion prevention at 8 bar pressure

- UV stability maintaining 90% elongation after 3,000 hours exposure

Electrification-Ready Sealing Implementations

A recent project for battery-electric vehicles achieved:

| Parameter | Target | Result |

|---|---|---|

| Drag Coefficient | ≤0.25 | 0.23 |

| Thermal Isolation | Δ15°C | Δ18°C |

| Assembly Time | 120s | 98s |

Automotive Sealing Strip Series: Shaping Mobility Futures

With 73% of Tier 1 suppliers now requiring recyclable materials, factories are developing bio-based TPV compounds that reduce carbon footprint by 40%. Exporters integrating AI-driven quality control systems report 99.2% first-pass yield rates, positioning the automotive sealing strip series at the forefront of sustainable manufacturing innovation.

(automobile sealing strip series)

FAQS on automobile sealing strip series

Q: What materials are commonly used in automobile sealing strip series products?

A: Automobile sealing strips are typically made from EPDM rubber, TPV, or silicone, ensuring durability, weather resistance, and noise reduction for vehicles.

Q: How can I identify a reliable automobile sealing strip series exporter?

A: Look for exporters with certifications like ISO 9001, proven industry experience, and positive client testimonials to ensure quality and reliability.

Q: What customization options do automobile sealing strip series factories offer?

A: Factories often provide tailored solutions for size, shape, material, and color to meet specific vehicle models or OEM requirements.

Q: Are automobile sealing strip series products tested for safety standards?

A: Yes, reputable manufacturers conduct rigorous testing for UV resistance, temperature tolerance, and waterproofing, complying with global automotive standards like IATF 16949.

Q: What is the typical production lead time for automobile sealing strip series orders?

A: Lead times vary but generally range from 15-30 days, depending on order volume, customization complexity, and factory capacity.

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025