China Extrusion Silicone Keder Seg - High-Quality Custom Solutions

Sep . 17, 2024 08:37 Back to list

China Extrusion Silicone Keder Seg - High-Quality Custom Solutions

China Extrusion Silicone Keder Seg Revolutionizing Industrial Applications

The rise of advanced materials has significantly transformed various industries, with silicone being at the forefront due to its exceptional properties. Among the many innovative silicone products emerging in the market, China extrusion silicone keder segments are gaining increased attention for their versatility and functionality. This article delves into the characteristics, manufacturing process, applications, and benefits of silicone keder segments, shedding light on why they are becoming a preferred choice in different sectors.

China Extrusion Silicone Keder Seg Revolutionizing Industrial Applications

One of the key advantages of silicone keder segments is their ability to withstand extreme temperatures, ranging from -50°C to over 200°C. This thermal resistance makes them suitable for use in environments where plastic materials would fail. Additionally, silicone is inherently UV resistant and can endure exposure to harsh weather conditions without degrading. This durability ensures that silicone keder segments maintain their structural integrity and performance over extended periods, making them ideal for outdoor applications, such as marine and automotive industries.

china extrusion silicone keder seg

The manufacturing process of silicone keder segments in China involves high-precision extrusion techniques. Advanced machinery is utilized to ensure that each segment is produced with consistent dimensions and superior quality. The process allows for the incorporation of various additives, such as colors and UV stabilizers, enhancing the aesthetic appeal and functionality of the segments. Furthermore, manufacturers often adhere to strict quality control measures, ensuring that the final product meets rigorous industry standards.

Silicone keder segments find applications across a broad spectrum of industries. In the automotive sector, they are employed for window seals, door trims, and other parts that require a flexible, durable barrier against water and air infiltration. In the marine industry, silicone keder is used to secure canvas covers and tarpaulins, providing a reliable shield against the elements. Additionally, they are commonly found in construction and HVAC systems, where they are used for insulation and sealing applications.

The benefits of silicone keder segments extend beyond their physical properties. They are lightweight, which simplifies installation processes, and can be easily integrated into existing systems. Their flexibility allows for easy handling, adapting to various design specifications without compromising on quality. Moreover, silicone keder segments are non-toxic and environmentally friendly, providing a sustainable option for manufacturers and consumers alike.

In conclusion, China extrusion silicone keder segments represent a remarkable advancement in material technology, offering unparalleled durability and versatility across numerous applications. As industries continue to evolve and demand more efficient solutions, the adoption of silicone-based products will undoubtedly play a crucial role in shaping the future of manufacturing and construction. Therefore, embracing silicone keder segments not only enhances product performance but also fosters a commitment to sustainability and innovation.

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

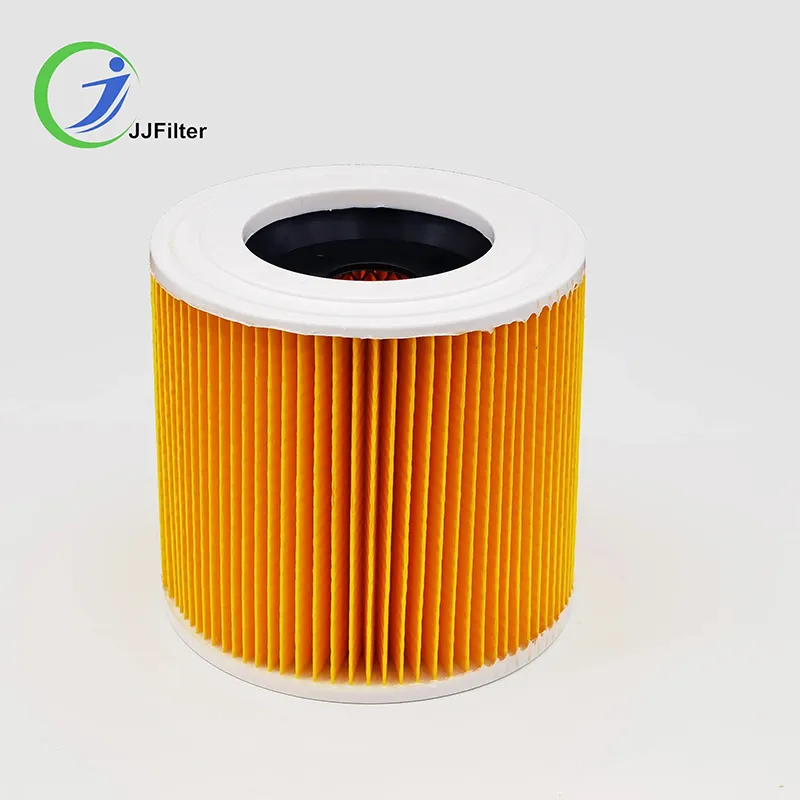

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025