rubber seal strip factories

Nov . 02, 2024 08:31 Back to list

rubber seal strip factories

Exploring the World of Rubber Seal Strip Factories

Rubber seal strips play an essential role in various industries, providing seals that ensure durability, flexibility, and resilience in applications ranging from automotive manufacturing to construction. These strips are integral components for equipment and products requiring protection against dust, water, temperature variations, and other environmental factors. With the growing demand for high-quality rubber seal solutions, numerous factories have emerged, specializing in the production of these vital components.

Rubber seal strip factories are equipped with advanced technology to ensure precision and efficiency in their manufacturing processes. They utilize a variety of rubber compounds, including EPDM (ethylene propylene diene monomer), silicone, and neoprene, which can be custom-formulated depending on the specific requirements of their clients. This diversity of materials allows factories to produce seals that meet a wide range of temperature and environmental conditions.

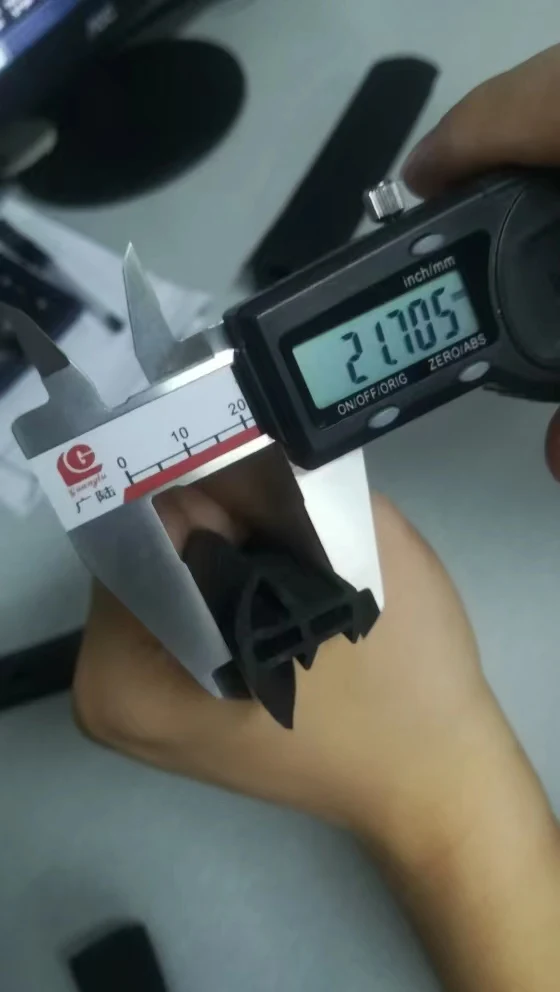

One of the critical aspects of rubber seal strip manufacturing is the focus on quality assurance. Factories implement rigorous testing protocols to ensure that their products meet industry standards and client specifications. Tests might include tensile strength, compression set, weather resistance, and ozone resistance assessments. By adhering to strict quality control measures, these factories establish a reputation for reliability and excellence in their output.

rubber seal strip factories

Additionally, sustainability is increasingly becoming a key concern in the manufacturing sector, including rubber production. Many rubber seal strip factories are embracing environmentally friendly practices, such as recycling waste materials, using bio-based rubber alternatives, and optimizing energy consumption during production. These efforts not only help protect the environment but also appeal to a growing market of eco-conscious consumers.

The design and engineering teams within rubber seal strip factories work closely with clients to develop customized solutions tailored to specific applications. This collaboration is crucial in various sectors, such as automotive, aerospace, and construction, where seal performance is paramount. By utilizing CAD (computer-aided design) software, manufacturers can create intricate profiles and designs that meet the precise requirements of their clients.

The versatility of rubber seal strips means they are used in countless applications. In automobiles, they help to prevent water ingress, reduce noise, and improve thermal insulation. In construction, rubber seals are vital for window frames, doors, and HVAC systems, contributing to energy efficiency and comfort in buildings. Their role in industrial machinery is equally significant, providing protection against contaminants and ensuring operational efficiency.

In conclusion, rubber seal strip factories are pivotal in producing components that enhance the performance and longevity of a multitude of products across various industries. With their commitment to quality, customization, and sustainability, these factories not only meet the current market demands but also pave the way for a more resilient and environmentally friendly future. As technology advances and the need for effective sealing solutions continues to grow, the importance of these factories will undoubtedly increase, solidifying their role in the global manufacturing landscape.

-

Top Window Seal Strip Adhesive Companies | Strong Weatherproofing

NewsAug.01,2025

-

Premium Oil Filter for Can-Am Outlander 2003-2017 420256188

NewsJul.31,2025

-

Hightech Injection LED Module size6414: Premium LED Lighting

NewsJul.31,2025

-

Factory Hot Sale Thin Silicone Sewn Strip Roll Wholesale, Durable & Flexible

NewsJul.30,2025

-

Oil Filter H F123 For Kawasaki KL250 KL600 KL650 KLX650 1977-2016

NewsJul.29,2025

-

Vacuum Cleaner Parts for Karcher AD2 AD3 AD4 6.415-953.0 Filters

NewsJul.29,2025