Factories Producing High-Quality Window Strip Seals for Energy Efficiency and Durability

Oct . 16, 2024 13:33 Back to list

Factories Producing High-Quality Window Strip Seals for Energy Efficiency and Durability

Understanding Window Strip Seal Factories Importance and Innovations

Window strip seals, also known as weatherstripping or window seals, play a vital role in enhancing the energy efficiency and comfort of buildings. As the demand for energy-efficient solutions increases, the production of these essential components has become a significant area of focus for manufacturers worldwide. This article will delve into the operations of window strip seal factories, examining their importance, the materials used, innovative technologies involved, and the future of this crucial industry.

The Importance of Window Strip Seals

Window strip seals are designed to fill the gaps around windows, preventing air leaks and ensuring that indoor environments remain thermally controlled. Effective seals contribute to energy conservation by minimizing heat loss during winter and keeping cool air inside during summer. This not only leads to lower energy bills for homeowners and businesses but also enhances overall comfort. Additionally, high-quality window seals contribute to noise reduction, improving living conditions in urban areas where external noise is a significant issue.

Materials Used in Manufacturing

The materials used in the production of window strip seals vary widely, catering to different climate conditions and application needs. Common materials include

1. Foam Flexible and easy to install, foam strips are popular for their excellent insulation properties. They are often used in residential applications for cost-effective sealing solutions.

2. Vinyl Known for its durability and resistance to weather elements, vinyl strips are frequently used in commercial buildings. They provide a higher degree of protection against moisture and temperature fluctuations.

3. Rubber Particularly effective for heavy-duty applications, rubber seals offer robust performance in extreme weather conditions. Their elasticity ensures a tight fit and longevity.

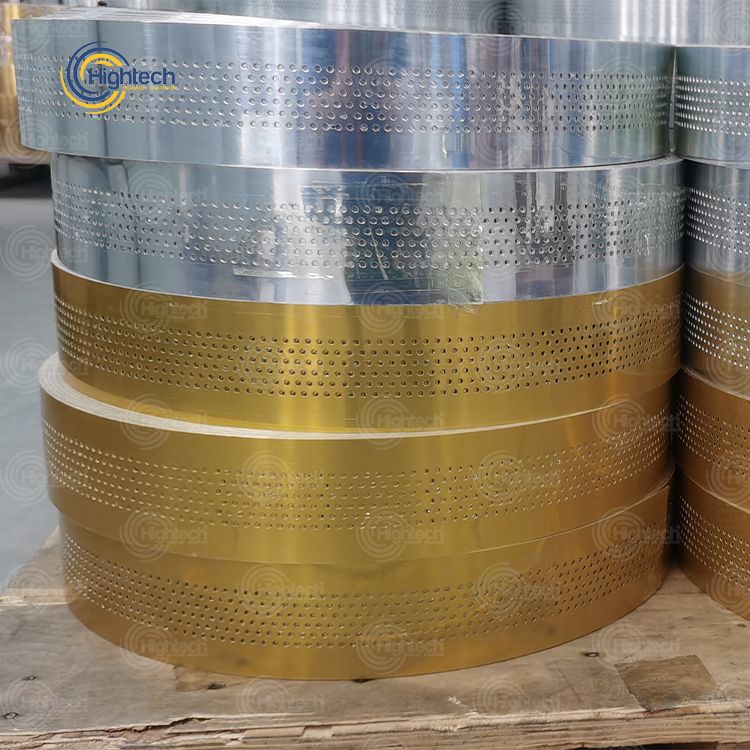

4. Metal For specific applications requiring high durability, metal strips can be used. These are often found in industrial settings where mechanical strength is paramount.

window strip seal factories

Innovations in Production Technologies

The production of window strip seals has seen significant advancements in technology over the years. Modern manufacturing processes now utilize automation and precision engineering to enhance the efficiency and quality of these products. Some key innovations include

1. Customization With advancements in computer-aided design (CAD) software, factories can now create customized window strip seals tailored to specific window dimensions and customer requirements.

2. Sustainable Practices As environmental concerns rise, many factories are adopting sustainable practices. This includes sourcing eco-friendly materials and implementing recycling programs for production waste.

3. Smart Technology The integration of smart technology into window seals is an emerging trend. Some manufacturers are exploring seals equipped with sensors that can detect changes in internal and external temperatures, providing data for better energy management in buildings.

The Future of Window Strip Seal Factories

The future of window strip seal factories is closely tied to the evolution of building standards and practices. As construction regulations around energy efficiency tighten, the demand for high-quality seals is expected to grow. Furthermore, the shift toward smart building solutions will drive innovation in window strip seal technologies, leading to more advanced products that provide enhanced functionality.

The global market for window strip seals is also projected to expand as awareness of energy conservation and eco-friendly building practices increases. Factories that prioritize quality, sustainability, and innovative technologies will thrive in this evolving landscape, meeting the needs of both residential and commercial clients.

In conclusion, window strip seal factories are an integral part of the construction industry, providing essential products that enhance energy efficiency and comfort. By embracing innovative manufacturing processes and sustainable practices, these factories are well-positioned to meet the challenges and opportunities of the future, contributing to a more energy-efficient built environment.

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025

-

Leading LED Neon Rope Light Outdoor Companies & Exporters

NewsAug.21,2025