Durable Rubber Sealing Strip for Enhanced Protection and Performance in Various Applications

දෙසැ. . 11, 2024 04:14 Back to list

Durable Rubber Sealing Strip for Enhanced Protection and Performance in Various Applications

High-Quality Rubber Sealing Strips Essential Components for Performance and Durability

In today's fast-paced industrial landscape, the demand for reliable and effective sealing solutions has never been higher. High-quality rubber sealing strips are becoming indispensable in a variety of sectors, including automotive, construction, aerospace, and manufacturing. These strips play a crucial role in providing durability, enhancing performance, and ensuring safety across numerous applications.

Rubber sealing strips are designed to create airtight and watertight seals that prevent the ingress of air, water, dust, and other contaminants. The materials used in manufacturing these strips significantly influence their performance. High-quality rubber, often silicone or EPDM (ethylene propylene diene monomer), demonstrates excellent elasticity, resilience, and resistance to harsh environmental conditions. This makes it an ideal choice for sealing strips that must withstand extreme temperatures, UV exposure, and chemical corrosion.

High-Quality Rubber Sealing Strips Essential Components for Performance and Durability

In construction, rubber sealing strips are vital for enhancing the longevity and energy efficiency of buildings. They are used in windows, doors, and roofing systems to minimize energy loss through gaps and cracks. By installing high-quality seals, builders can significantly reduce heating and cooling costs, contributing to a more sustainable and environmentally friendly construction process.

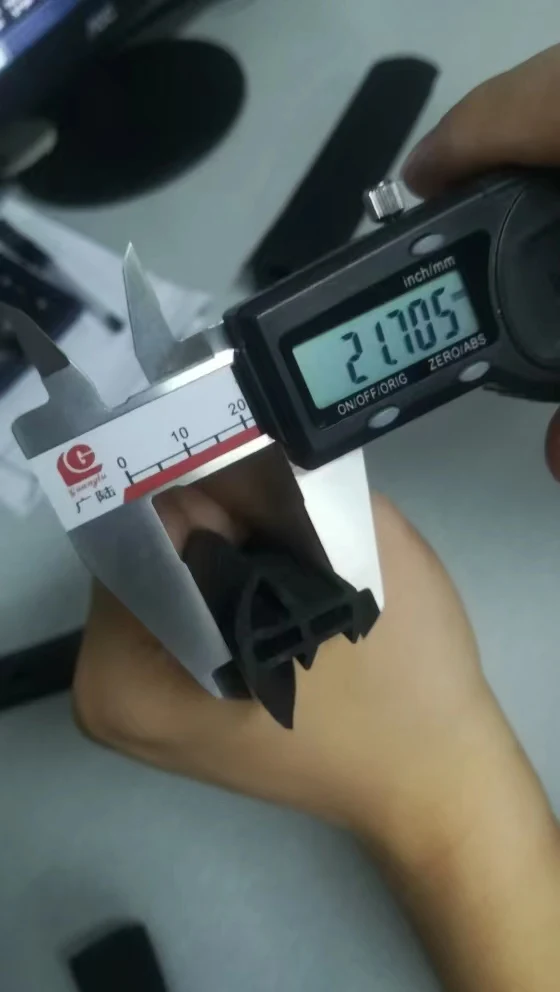

high quality rubber sealing strip

Another critical aspect of high-quality rubber sealing strips is their ability to maintain performance over time. Unlike lower-quality materials that can degrade quickly, causing leaks and failures, high-quality rubber strips are engineered to resist wear and tear. With proper installation and maintenance, these sealing strips can last for years, reducing the need for frequent replacements and ultimately saving costs.

Moreover, the safety aspect cannot be overlooked. In many applications, especially in the automotive and aerospace sectors, the integrity of seals is paramount. High-quality rubber sealing strips help prevent the escape of harmful gases and liquids, ensuring that vehicles and aircraft operate safely and efficiently. This is particularly important in critical systems where sealing failures could lead to catastrophic consequences.

The manufacturing process for high-quality rubber sealing strips typically involves rigorous quality control measures. This includes testing for tensile strength, elongation, and compression set, as well as exposure to extreme temperatures and chemicals. These tests ensure that the final product meets the exacting standards required for various applications, thereby providing peace of mind to manufacturers and end-users alike.

In conclusion, high-quality rubber sealing strips are essential components that contribute significantly to the performance, durability, and safety of various applications. Their versatility, longevity, and resistance to harsh environments make them indispensable in a myriad of industries. With the ongoing advancements in materials science and manufacturing techniques, the future of sealing solutions looks promising, paving the way for even more innovative and effective sealing applications. Whether you are in automotive, aerospace, or construction, investing in high-quality rubber sealing strips is an investment in efficiency, safety, and long-term value.

-

Replacement Filter Screen for Karcher SE3001 SE2001 Vacuum

NewsAug.04,2025

-

Karcher A2004 Vacuum Cartridge Filter Replacement - Durable & Efficient

NewsAug.03,2025

-

Karcher WD/MV HEPA Cartridge Filters | Dust Control Experts

NewsAug.02,2025

-

Top Window Seal Strip Adhesive Companies | Strong Weatherproofing

NewsAug.01,2025

-

Premium Oil Filter for Can-Am Outlander 2003-2017 420256188

NewsJul.31,2025

-

Hightech Injection LED Module size6414: Premium LED Lighting

NewsJul.31,2025