Rubber T Seal Strip Manufacturers for Quality Seal Solutions and Custom Fabrication

Nov . 04, 2024 16:40 Back to list

Rubber T Seal Strip Manufacturers for Quality Seal Solutions and Custom Fabrication

Exploring Rubber T Seal Strip Factories Innovations and Applications

Rubber T seal strips are essential components used across various industries for sealing, cushioning, and insulation purposes. Particularly renowned for their effectiveness in creating airtight and watertight seals, these strips find their applications in automobiles, aerospace, construction, and appliance manufacturing. In this article, we will delve into the significance of rubber T seal strip factories, their innovative manufacturing processes, and their diverse applications.

What is a Rubber T Seal Strip?

A rubber T seal strip is characterized by its T-shaped cross-section. The design allows it to fit snugly into grooves and gaps, making it ideal for sealing mechanisms in doors, windows, hoods, and many other applications. Made from various materials, including synthetic rubber like EPDM (Ethylene Propylene Diene Monomer) and Neoprene, these strips ensure longevity and resilience against environmental factors.

The Manufacturing Process

Rubber T seal strip factories employ advanced manufacturing techniques to produce high-quality products. The process typically begins with the selection of raw materials, where manufacturers choose the appropriate rubber compounds based on the intended application and environmental factors.

The compounding process follows, during which additives like fillers, antioxidants, and accelerators are mixed with rubber to enhance properties such as durability and flexibility. This mixture is then formed into strips using techniques like extrusion or molding.

Extrusion is a popular method where heated rubber is forced through a die to create the T-shaped profile. This continuous process allows for uniformity in size and shape. In contrast, molding involves pouring the rubber mixture into a pre-shaped mold, which is especially useful for custom designs or specific dimensions.

Once the seals are formed, they undergo curing, a crucial step that involves heating to set the rubber's properties. Quality control measures, including testing for tensile strength, elongation, and flexibility, ensure that only the best products leave the factory.

rubber t seal strip factories

Innovations in Nature and Technology

Rubber T seal strip factories are continually evolving, embracing technological advancements to improve efficiency and sustainability. Automation plays a significant role in modern manufacturing, enabling factories to increase production speed while maintaining high standards of quality.

Moreover, many manufacturers are investing in eco-friendly practices by utilizing recycled rubber and environmentally safe additives. This shift not only reduces waste but also appeals to an increasingly eco-conscious market.

On the technological side, innovations in design software allow for precise customization, which is essential for industries requiring specific dimensions and functionalities. Factories can now produce seals tailored to unique specifications, meeting the diverse needs of their customers.

Applications of Rubber T Seal Strips

The versatility of rubber T seal strips opens doors to numerous applications. In the automotive industry, they are used around doors and windows to provide insulation against weather and noise. In aerospace, they are crucial for maintaining cabin pressure and reducing noise levels.

In construction, these seals ensure that windows and doors are airtight, thereby enhancing energy efficiency in buildings. Additionally, rubber T seal strips play a vital role in appliances such as refrigerators and washing machines, where effective sealing is essential for optimal operation.

Conclusion

Rubber T seal strip factories are vital players in various industries, providing products that offer essential sealing solutions. With innovative manufacturing processes and a focus on sustainability, these factories are well-positioned to meet the demands of an ever-changing market. Their commitment to quality and adaptability ensures that rubber T seal strips remain integral components in numerous applications, contributing significantly to the efficiency and effectiveness of modern technology. As we move forward, the importance of these factories will only continue to grow, reflecting the critical role that effective sealing solutions play in our daily lives.

-

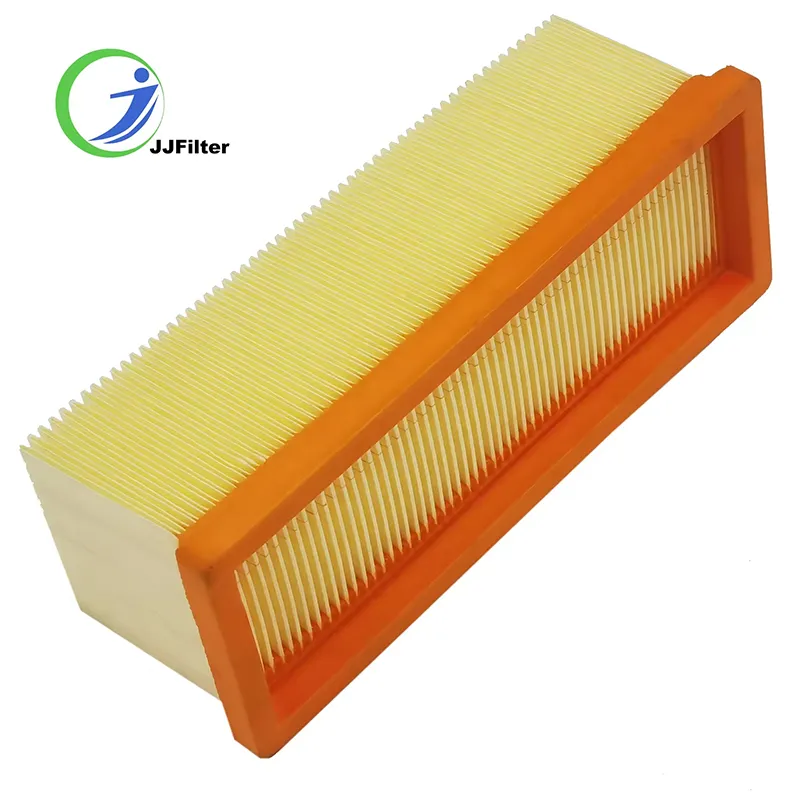

Air Filter Replacement Core for K-archer WD4.200 WD5.200 WD4 WD5

NewsJul.28,2025

-

Top Window Seal Strip Adhesive Companies for Durable Solutions

NewsJul.27,2025

-

Factory price Replacement Karchers A2004 Wet & Dry Vacuum Cleaners Cartridge Filter

NewsJul.26,2025

-

Factory Hot Sale Recycled Green Elastic Profiles Wholesale Supplier

NewsJul.25,2025

-

Hi flo Oil Filter H F155 for KT M 250 EXC Racing 2003-2006, OEM Quality

NewsJul.24,2025

-

Top LED Neon Rope Light Outdoor Companies – Durable & Weatherproof Solutions

NewsJul.23,2025