Innovative Solutions for Durable Strip and Seal Flooring from Leading Manufacturers in the Industry

Aug . 09, 2024 04:30 Back to list

Innovative Solutions for Durable Strip and Seal Flooring from Leading Manufacturers in the Industry

The Rise of Strip and Seal Floors An Overview of the Manufacturing Process

In recent years, the flooring industry has witnessed a significant transformation with the introduction of innovative flooring solutions, among which strip and seal floors have gained considerable popularity. These floors are not just aesthetically pleasing but also robust, making them a favored choice for both residential and commercial spaces. Understanding the manufacturing process and benefits of strip and seal floors is essential for homeowners, builders, and designers alike.

What are Strip and Seal Floors?

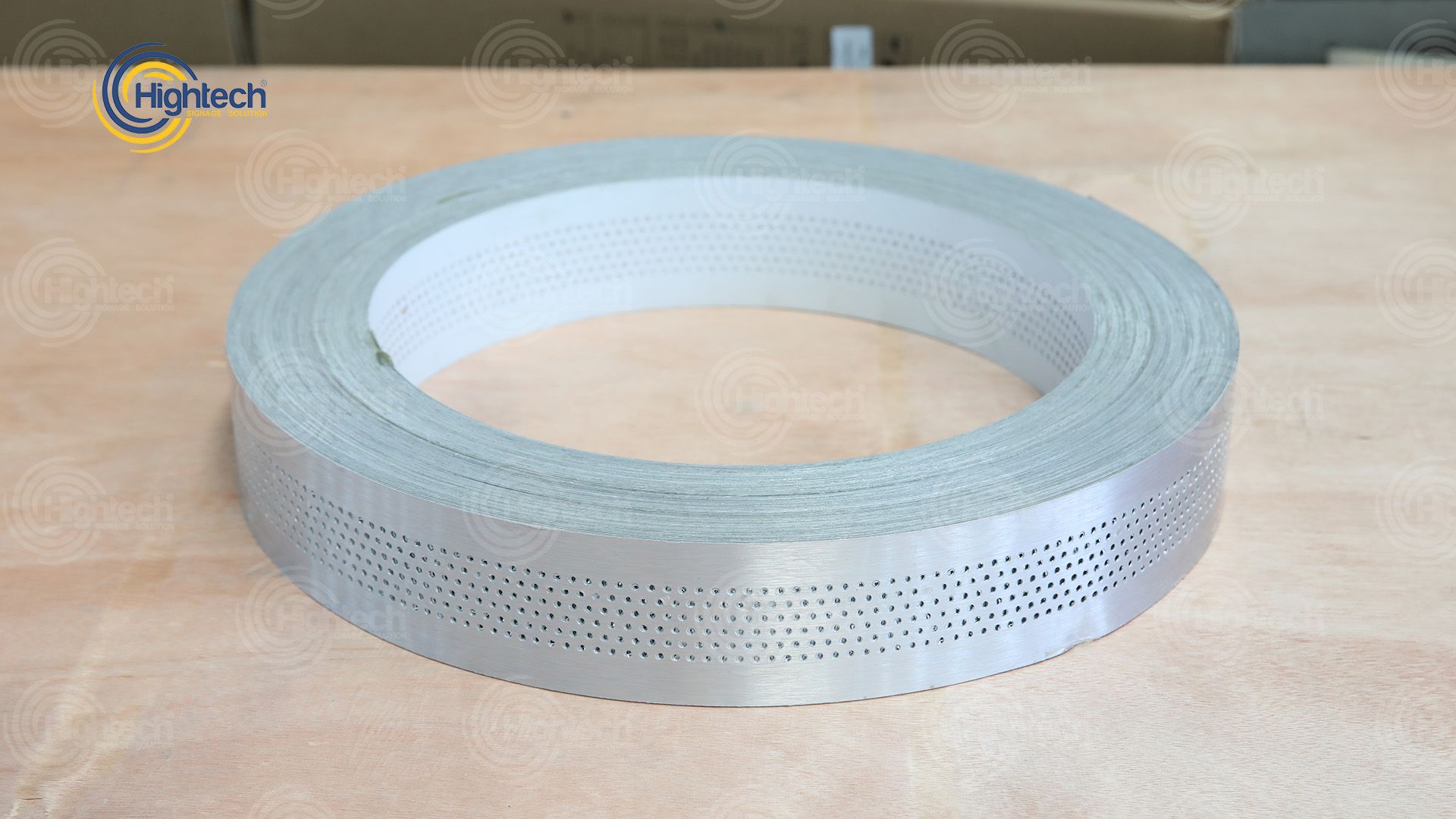

Strip and seal floors refer to a specific flooring system where a layer of surface treatment is applied to create a protective seal over a resilient or rigid substrate. This seal enhances the floor's durability, resistance to wear, and overall appearance. Often made from vinyl, linoleum, or hardwood, strip and seal flooring is designed to withstand high traffic, making it ideal for locations such as schools, hospitals, and retail outlets.

The Manufacturing Process

The manufacturing of strip and seal floors involves a series of meticulous steps to ensure the final product meets industry standards and customer expectations.

1. Material Selection The process begins with careful selection of raw materials. Depending on the desired aesthetic and functionality, manufacturers source high-quality vinyl, linoleum, or hardwood. Environmental sustainability is also considered, with many manufacturers opting for eco-friendly materials.

2. Design and Cutting Once the materials are chosen, the next step is designing the product. Advanced software is often employed to create precise designs that can be cut to size. This design phase is critical, as it lays the foundation for the final appearance of the floor.

3. Layering In strip and seal flooring, multiple layers are often combined to enhance durability. The base layer provides structural support, while middle layers offer cushioning and soundproofing characteristics. The top layer, which is usually the decorative element, is designed to withstand scratches, stains, and fading.

strip and seal floors manufacturer

4. Sealing The sealing process is vital, as it provides the protective barrier that characterizes strip and seal floors. Manufacturers apply a specialized sealant that not only preserves the integrity of the material but also makes it easier to clean and maintain. This seal protects against moisture and debris, prolonging the life of the flooring.

5. Quality Control After the manufacturing process is complete, rigorous quality control measures are implemented. Each batch of flooring undergoes testing to ensure it meets specific performance criteria, including resilience, color fastness, and ease of cleaning.

6. Packaging and Distribution Once the flooring passes quality checks, it is packaged for distribution. Manufacturers often provide detailed installation instructions and maintenance guidelines to ensure customers can enjoy their new floors for years to come.

Benefits of Strip and Seal Floors

The advantages of choosing strip and seal floors are abundant. First and foremost, their durability makes them a cost-effective solution in the long run, as they require fewer replacements and repairs compared to traditional flooring options. Additionally, their ease of maintenance—requiring only regular cleaning and periodic resealing—adds to their appeal for busy environments.

Moreover, strip and seal floors come in a variety of designs, colors, and textures, allowing for customization that can suit any design aesthetic. Whether aiming for a modern look or a classic feel, there is a strip and seal option to match.

Conclusion

In conclusion, strip and seal floors represent an innovative evolution in flooring technology. By understanding the manufacturing process and the benefits associated with these floors, individuals and businesses can make informed choices that enhance their spaces' beauty and functionality. As the demand for quality and durability continues to grow, strip and seal floors are likely to remain a prominent choice on the market for years to come.

-

Karcher A2004 Vacuum Cartridge Filter Replacement - Durable & Efficient

NewsAug.03,2025

-

Karcher WD/MV HEPA Cartridge Filters | Dust Control Experts

NewsAug.02,2025

-

Top Window Seal Strip Adhesive Companies | Strong Weatherproofing

NewsAug.01,2025

-

Premium Oil Filter for Can-Am Outlander 2003-2017 420256188

NewsJul.31,2025

-

Hightech Injection LED Module size6414: Premium LED Lighting

NewsJul.31,2025

-

Factory Hot Sale Thin Silicone Sewn Strip Roll Wholesale, Durable & Flexible

NewsJul.30,2025