Custom Flexible Plastic Extrusion Profile Manufacturing Solutions for Various Industries

Oct . 01, 2024 08:26 Back to list

Custom Flexible Plastic Extrusion Profile Manufacturing Solutions for Various Industries

Flexible Plastic Extrusion Profile Factory Innovation in Manufacturing

In the ever-evolving landscape of manufacturing, flexible plastic extrusion has emerged as a crucial component for producing a wide range of products across various industries. The process involves shaping molten plastic into continuous profiles that can be cut to desired lengths. This method is particularly versatile and efficient, making it an attractive option for both manufacturers and consumers alike. A flexible plastic extrusion profile factory can serve numerous sectors, from automotive to construction, offering tailored solutions that meet specific requirements.

Understanding Flexible Plastic Extrusion

At its core, plastic extrusion is a manufacturing process involving the continuous shaping of plastic material, typically in pellet form. The raw plastic is fed into an extruder, where it is heated, mixed, and forced through a die to create a specific profile. The term flexible refers to the ability to produce various shapes and sizes while allowing for significant alterations in the design based on client needs. This adaptability is particularly beneficial in meeting the dynamic demands of different industries.

Advantages of Flexible Plastic Extrusion

The flexibility of this manufacturing technique offers a multitude of advantages. First and foremost, it allows for mass production of customized items, enabling companies to develop unique products that stand out in the market. This customization can include different materials, colors, and dimensions, catering to specific applications without compromising quality.

Moreover, the process is highly efficient, allowing for a rapid production rate while maintaining consistency and precision. Automated systems in an extrusion profile factory can significantly reduce labor costs and minimize human error, enhancing operational efficiency. Additionally, flexible plastic materials are often lightweight and cost-effective, which can lead to savings in shipping and handling.

Applications in Various Industries

The applications of flexible plastic extrusion profiles are vast. In the automotive industry, for instance, extruded profiles can be used for gaskets, seals, and other components that require flexibility and durability. These profiles are essential for improving the performance, safety, and aesthetics of vehicles.

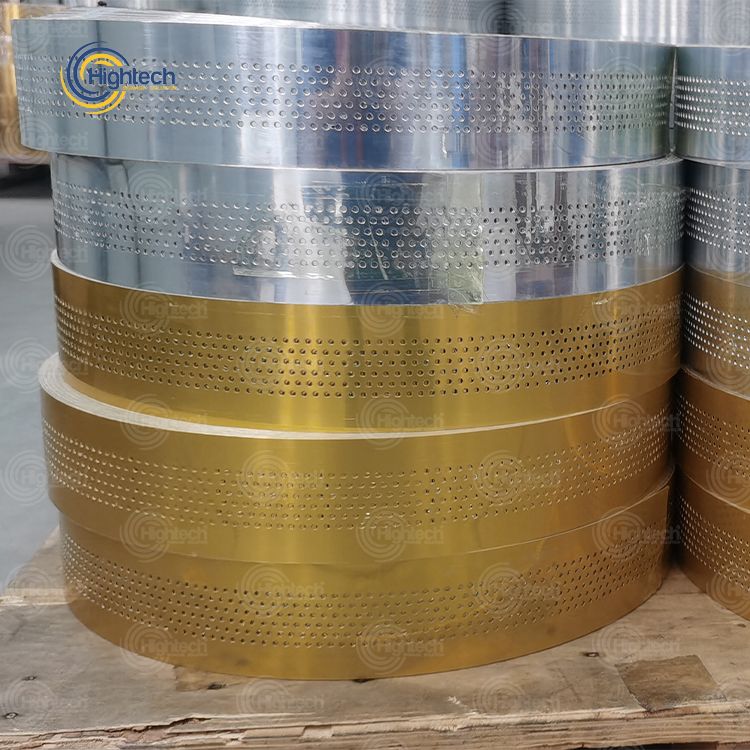

flexible plastic extrusion profile factory

In the construction sector, flexible plastic profiles play a critical role in creating components such as window frames, door seals, and roofing materials. The robustness and resistance to various environmental factors make them ideal for use in residential and commercial buildings.

Additionally, in the packaging industry, flexible plastic extrusion is used to manufacture packaging solutions that are not only functional but also promote sustainability. With growing concerns over plastic waste, many manufacturers are focusing on using recyclable materials in their extrusion processes, aligning with global sustainability goals.

Technological Advancements

The plastic extrusion industry has seen significant technological advancements which have further enhanced the efficacy of the process. Innovations in die design and temperature control have led to better product quality and reduced waste. Additionally, computer-aided design (CAD) and computer numerical control (CNC) technologies have streamlined the design process, allowing for precise specifications and quicker turnaround times.

Furthermore, advancements in materials science have opened the door to new possibilities. Biodegradable and eco-friendly plastics are becoming increasingly popular, and extrusion processes are adapting to accommodate these new materials. This shift not only caters to consumer demand for sustainable options but also reflects the industry's commitment to reducing environmental impact.

Future Outlook

As the demand for flexible plastic extrusion profiles continues to grow, the industry is poised for further growth and innovation. Manufacturers who adapt to emerging technologies and sustainability practices will be at the forefront of this expanding market. The integration of artificial intelligence and automation in factories is expected to enhance efficiency, reduce costs, and improve product quality even further.

In conclusion, a flexible plastic extrusion profile factory represents the intersection of innovation and functionality. With its broad applications and advantages, flexible plastic extrusion is an integral part of modern manufacturing, shaping the future of products we interact with daily. As industries continue to evolve, the importance of these manufacturing processes will grow, driving further exploration and development in the field.

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025

-

Leading LED Neon Rope Light Outdoor Companies & Exporters

NewsAug.21,2025