door sealing strip factory

дец . 21, 2024 17:13 Back to list

door sealing strip factory

The Significance of Door Sealing Strips and the Role of Factories in Their Production

In modern construction and renovation projects, maintaining energy efficiency, sound insulation, and comfort is paramount. One of the often-overlooked components that contribute to these factors is the door sealing strip. These strips play a critical role in enhancing the performance of doors, acting as barriers to the elements, unwanted noise, and dust. The production of these essential components is handled by specialized factories that understand the nuances of material selection, manufacturing processes, and quality control.

What are Door Sealing Strips?

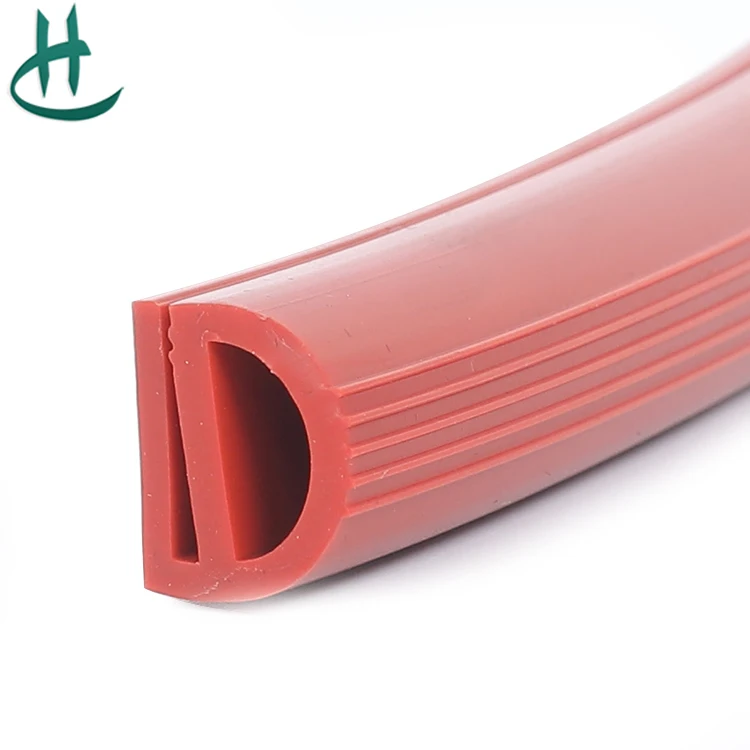

Door sealing strips, also known as weatherstripping, are materials applied to the edges of doors to create a snug fit that prevents drafts and seals in temperature-controlled air. Available in various forms such as adhesive strips, rubber gaskets, foam tapes, and silicone options, these strips are designed to effectively seal gaps between the door and its frame. The choice of material can vary significantly, impacting durability, insulation properties, and ease of installation.

Benefits of Door Sealing Strips

1. Energy Efficiency One of the primary advantages of using door sealing strips is their ability to improve energy efficiency. By preventing air leaks, these seals reduce the workload on heating and cooling systems. This reduction leads to lower energy bills and extends the lifespan of HVAC systems.

2. Sound Insulation Doors are often responsible for noise infiltration from outside or between rooms. High-quality sealing strips can significantly improve sound insulation, making living spaces more comfortable and serene.

3. Protection from Elements Sealing strips protect against water, dust, and pests. Properly installed strips can keep rainwater from seeping in and stopping insects from entering homes, thereby enhancing the overall living experience.

4. Aesthetic Appeal Modern sealing strips are designed not only for functionality but also for aesthetics. They can complement the design of the door and surrounding decor, ensuring that they are both effective and visually pleasing.

The Manufacturing Process

door sealing strip factory

The production of door sealing strips involves several critical steps, each requiring meticulous attention to detail. Here’s a brief overview of the manufacturing process

1. Material Selection The first step in producing door sealing strips is selecting the appropriate materials. Manufacturers often opt for durable options like EPDM rubber, silicone, or closed-cell foam, which offer the best performance in terms of longevity and insulation.

2. Molding and Extrusion Following material selection, the chosen material undergoes molding or extrusion to achieve the desired shape and size. For instance, rubber strips are often molded into specific profiles that fit various door dimensions.

3. Cutting and Finishing Once the strips are formed, they are cut to specific lengths and undergo finishing processes. This can include surface treatments or adding adhesives to ensure easy installation.

4. Quality Control Before the sealing strips are packaged and shipped, they must pass rigorous quality control tests. Factors such as flexibility, sealing capability, durability, and resistance to environmental factors are evaluated to ensure that only high-quality products reach the market.

5. Packaging and Distribution Finally, the finished products are packaged for distribution. Factories may have various marketing strategies to reach both wholesale distributors and consumers, emphasizing the benefits of their sealing products.

The Future of Door Sealing Strip Factories

As environmental awareness increases, door sealing strip factories are adapting to meet new demands. Innovations in sustainable materials are leading the way in production, enabling manufacturers to offer eco-friendly options without compromising performance. Moreover, advancements in technology are streamlining production processes, allowing factories to produce higher-quality sealing strips more efficiently.

In conclusion, door sealing strips are far more than simple accessories; they are vital components that contribute to energy efficiency, sound insulation, and comfort in homes and buildings. The factories dedicated to producing these strips play a crucial role in ensuring that consumers have access to high-quality, effective solutions. As the demand for energy efficiency and sustainable living grows, these factories will undoubtedly continue to evolve, meeting the needs of a changing market while enhancing the functionality and comfort of our spaces.

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025