Affordable Black PVC Price Strip Manufacturing Solutions for Your Business Needs

Novemba . 07, 2024 12:38 Back to list

Affordable Black PVC Price Strip Manufacturing Solutions for Your Business Needs

The Importance of Black PVC Price Strips Insights from the Factory

In the manufacturing sector, price strips serve a vital role, especially in the context of black PVC (polyvinyl chloride) products. Price strips not only convey vital information to consumers but also enhance the aesthetic appeal of the displays they accompany. This article will delve into the significance of black PVC price strips, the processes involved in their production in factories, and the evolving market dynamics surrounding them.

What Are Black PVC Price Strips?

Black PVC price strips are thin, flexible strips made from PVC plastic, typically utilized for displaying pricing tags or promotional information in retail settings. Commonly found in supermarkets, clothing stores, and other retail outlets, these strips are designed to securely hold labels while presenting a clean and professional appearance. The choice of black as a color is strategic, as it contrasts well with most label colors, ensuring that the pricing information is easily readable.

Advantages of Using PVC for Price Strips

1. Durability PVC is known for its resilience. Black PVC price strips can withstand daily wear and tear, environmental factors, and the rigors of a bustling retail environment. This makes them a cost-effective choice for long-term use.

2. Flexibility The malleability of PVC allows for various design configurations. Factories can produce price strips of different lengths and thicknesses to accommodate the specific needs of a business.

3. Aesthetic Appeal The sleek, shiny finish of black PVC adds a professional touch to displays. It enhances the overall look of products and draws customer attention, which can help improve sales.

4. Easy to Clean Retail environments can be prone to dust and grime; however, PVC can be easily wiped clean. This feature ensures that price strips maintain their attractive appearance over time, contributing to a positive shopping experience.

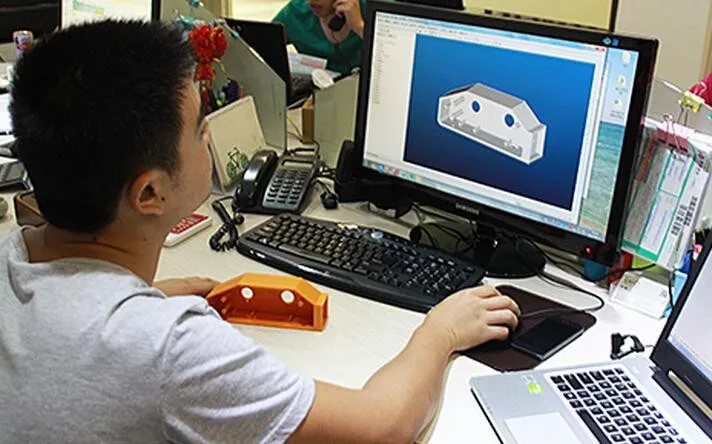

black pvc price strip factory

The Production Process

The manufacturing process of black PVC price strips involves several stages to ensure a high-quality product. Factories begin by sourcing quality PVC material, which is then melted and extruded into thin strips. This extrusion process allows for precise control over the dimensions and quality of the price strips.

Once the strips are formed, they undergo a rigorous quality control process. Factory workers examine the strips for consistency in color, thickness, and flexibility. Any defective strips are removed to maintain high standards. After passing quality checks, the strips are cut to size and packaged for distribution.

Market Trends

The market for black PVC price strips is witnessing several trends. Firstly, there is a growing demand for customization. Retailers are increasingly seeking unique designs that fit their branding and marketing strategies. Factories are responding by offering options for custom lengths, thicknesses, and even the possibility of adding business logos to the strips.

Additionally, the rise of e-commerce has brought about changes in physical retail. As brick-and-mortar stores adapt to compete with online shopping, unique merchandising solutions like black PVC price strips are seen as an essential tool to improve customer engagement.

Conclusion

In conclusion, black PVC price strips are more than just functional items; they are a pivotal element in the retail landscape. From their durability to aesthetic appeal, the benefits of these strips make them a preferred choice for retailers looking to enhance their displays. The manufacturing process in factories ensures that high-quality products meet the evolving needs of the market. As retail continues to adapt and evolve, black PVC price strips will likely remain an indispensable part of the merchandising toolkit, helping businesses capture customer attention and drive sales.

-

Factory Hot Sale Recycled Green Elastic Profiles Wholesale Supplier

NewsJul.25,2025

-

Hi flo Oil Filter H F155 for KT M 250 EXC Racing 2003-2006, OEM Quality

NewsJul.24,2025

-

Top LED Neon Rope Light Outdoor Companies – Durable & Weatherproof Solutions

NewsJul.23,2025

-

Top Window Seal Strip Adhesive Companies for Quality Sealing Solutions

NewsJul.22,2025

-

HighTech Injection LED Module Size 6414 - Efficient, Durable Lighting

NewsJul.22,2025

-

Top Window Seal Strip Adhesive Companies | Durable Weatherproof Seals

NewsJul.21,2025