t shaped rubber seal strip factories

అక్టో . 15, 2024 11:35 Back to list

t shaped rubber seal strip factories

The Importance of T-Shaped Rubber Seal Strips in Manufacturing

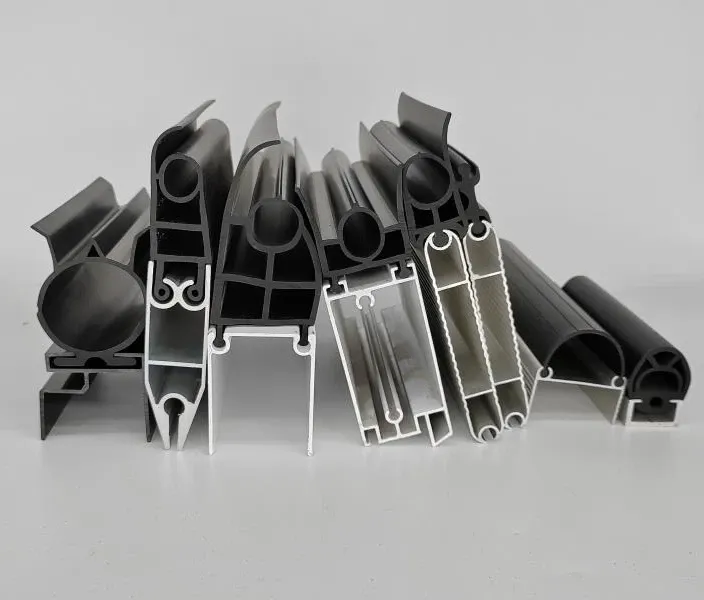

In the modern manufacturing landscape, the role of components such as T-shaped rubber seal strips cannot be overstated. These versatile strips are essential in a variety of applications, providing crucial sealing solutions for multiple industries, including automotive, construction, and appliances. With the growing demand for quality and efficiency, the factories that produce these rubber seal strips have become increasingly important.

The Importance of T-Shaped Rubber Seal Strips in Manufacturing

Manufacturing these strips involves precision engineering and high-quality materials. Most T-shaped rubber seal strips are made from durable materials like EPDM (ethylene propylene diene monomer), silicone, or PVC, which can withstand extreme temperatures and harsh environmental conditions. Factories specializing in rubber seal production invest in advanced machinery and technology to produce high volumes of these strips while maintaining strict quality control standards. This ensures that every strip meets industry regulations and performance benchmarks.

t shaped rubber seal strip factories

Moreover, the production process typically involves several key steps compounding, molding, and finishing. In the compounding stage, raw rubber is mixed with various additives to enhance its properties. The molding process then shapes the rubber into the desired T-shape, using techniques such as extrusion or compression molding. Finally, the finishing touches involve trimming and inspecting each strip to ensure it meets the specific requirements of clients.

The demand for T-shaped rubber seal strips continues to grow, driven by trends such as increased automation, demands for energy efficiency, and the need for improved product durability. This growth presents opportunities for factories to innovate and expand their product lines. Many manufacturers are exploring eco-friendly rubber alternatives to cater to the increasing consumer preference for sustainable products.

In conclusion, T-shaped rubber seal strip factories play a vital role in various industries by providing essential sealing solutions. Their ability to produce high-quality strips through advanced manufacturing processes not only enhances the performance of products but also contributes to the sustainability and efficiency of manufacturing operations. As industries evolve, so too will the technologies and materials used in the production of these essential components, paving the way for a future where performance and sustainability go hand in hand.

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025

-

Leading LED Neon Rope Light Outdoor Companies & Exporters

NewsAug.21,2025

-

Top Window Seal Strip Adhesive Manufacturers & Suppliers

NewsAug.19,2025

-

Top Window Seal Strip Adhesive Companies - Durable & Reliable

NewsAug.18,2025

-

Leading Window Seal Strip Adhesive Solutions & Companies

NewsAug.17,2025

-

Tineco A10 A11 S11 S12 Vacuum Roller Brush & Pre-Hepa Filter

NewsAug.16,2025