hand use aluminum manufacturer

Nov . 17, 2024 05:59 Back to list

hand use aluminum manufacturer

Hand-Use Aluminum Manufacturing A Comprehensive Overview

In a world increasingly driven by innovation and efficiency, the demand for versatile materials is soaring. Among these, aluminum has carved a niche for itself due to its unique properties, including lightweight, durability, and resistance to corrosion. A specific segment of the aluminum industry that has garnered attention is hand-use aluminum manufacturing, which caters to a diverse range of applications, from construction and automotive parts to consumer products and art.

The Significance of Aluminum

Aluminum is the most abundant metal in the Earth's crust and is widely used across various sectors. Its lightweight nature makes it ideal for applications where weight reduction is crucial, such as in aerospace and transportation. Additionally, its excellent malleability allows it to be easily shaped into different forms, making it suitable for custom manufacturing projects.

Hand-use aluminum refers to products made from aluminum that are primarily designed for manual handling or applications where precision and fine details are essential. This includes items like tools, decorative elements, and components that require a high degree of craftsmanship.

The Manufacturing Process

Producing hand-use aluminum components involves several critical steps

1. Aluminum Alloy Selection Different aluminum alloys possess varying physical and chemical properties. Manufacturers must select the appropriate alloy based on the intended use of the final product. Common alloys for hand-use applications include 6061 and 6063, known for their excellent strength-to-weight ratio and corrosion resistance.

2. Casting The chosen aluminum alloy is melted under high temperatures and poured into molds. This step allows manufacturers to create complex shapes and designs that would be challenging to achieve through other methods.

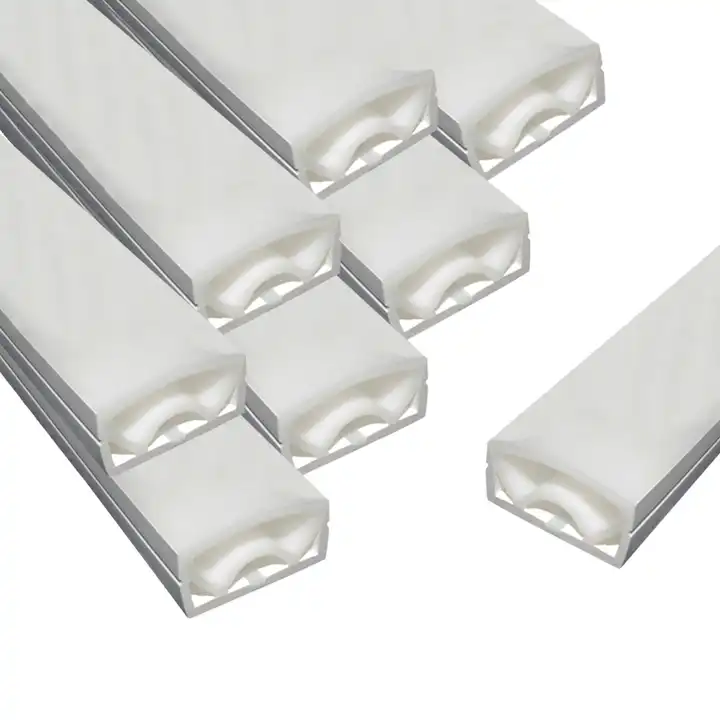

3. Extrusion In many cases, manufacturers employ extrusion techniques to create long, uniform profiles that can be cut down to size. Extrusion is particularly beneficial for creating components like handles, frames, and brackets.

hand use aluminum manufacturer

4. Machining After the initial formation, the components undergo machining processes such as cutting, drilling, and milling to achieve the desired dimensions and finish. This step is crucial for ensuring accuracy and fitting in applications that require tight tolerances.

5. Finishing The final step involves surface treatments such as anodizing, painting, or polishing to enhance aesthetics and provide additional protection against environmental factors. Anodizing, in particular, is well-regarded for increasing corrosion resistance and is widely used in decorative applications.

Applications of Hand-Use Aluminum

The applications of hand-use aluminum are extensive and diverse. In the construction industry, aluminum is favored for windows, doors, and curtain walls due to its strength and lightweight nature. In the automotive field, aluminum components are increasingly being used to reduce vehicle weight and improve fuel efficiency.

In the realm of consumer products, hand-use aluminum is prevalent in kitchen utensils, outdoor furniture, and electronic device casings. Additionally, artists and craftspeople utilize aluminum for sculptures and other decorative items, taking advantage of its malleability and resistance to corrosion.

Advantages of Hand-Use Aluminum

The benefits of hand-use aluminum manufacturing are numerous

- Lightweight This allows for easier handling and transport of products, reducing overall shipping costs. - Durability Aluminum is resistant to rust and corrosion, offering a longer lifespan than many other materials. - Recyclability Aluminum is one of the most recyclable materials, making it an environmentally friendly choice for consumers and manufacturers alike. - Versatility Its adaptability to various manufacturing processes means that it can be crafted into an almost limitless range of products.

Conclusion

As we move towards a more sustainable and efficient future, hand-use aluminum manufacturing stands out for its ability to combine functionality with environmental consciousness. With its broad array of applications and inherent advantages, aluminum continues to be a favored material among manufacturers, artisans, and consumers. Embracing the potential of aluminum not only nurtures innovation but also contributes to a more sustainable industrial landscape. As the industry advances, the focus will likely shift toward developing even more eco-friendly manufacturing techniques and exploring new alloy formulations, driving the hand-use aluminum sector into an exciting future.

-

Premium White Transparent PVC Adhesive Strip - Strong & Durable

NewsJun.06,2025

-

Premium Car Trim Strip for Enhanced Vehicle Protection

NewsJun.06,2025

-

Flexible White Transparent Silicone Strip Premium Quality Sealer

NewsJun.06,2025

-

Durable Plastic-Aluminum Channel Groove Belt Supplier

NewsJun.06,2025

-

Premium Aluminum-Plastic Edge Strip for Signage & Channel Edges

NewsJun.06,2025

-

Thin Silicone Strips for SEG Light Box Frames Durable Supplier & Pricelist

NewsJun.05,2025