Innovative Seal Strip Turbine Design for Enhanced Efficiency and Performance in Fluid Dynamics Applications

Hul . 26, 2024 13:32 Back to list

Innovative Seal Strip Turbine Design for Enhanced Efficiency and Performance in Fluid Dynamics Applications

Understanding Seal Strip Turbine Products A Comprehensive Overview

The realm of energy generation and mechanical engineering continuously evolves, with innovative technologies emerging to address the increasing demand for efficiency and sustainability. One such innovation is the seal strip turbine product, an essential component in various systems, including turbines, compressors, and fans. This article aims to explore the significance, functionality, and applications of seal strip turbine products, while also highlighting their advantages in modern engineering.

What is a Seal Strip Turbine Product?

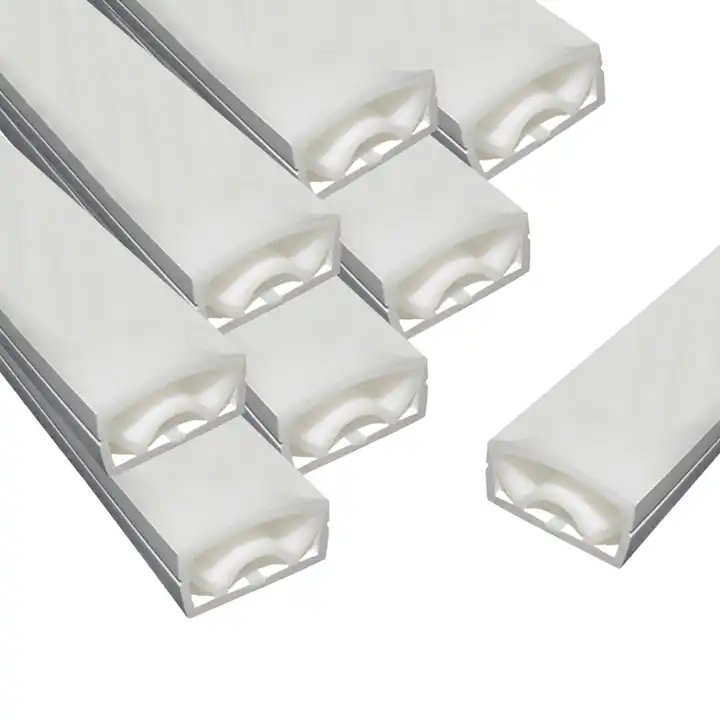

Seal strip turbine products are engineered components designed to create a seal between moving parts in a turbine or rotating machinery. These seals are vital in preventing the escape of gases or fluids, thereby maintaining the necessary pressure and efficiency within the system. Typically made from durable materials such as rubber, silicone, or thermoplastic elastomers, seal strips are designed to withstand extreme temperatures and pressures while providing reliable performance.

Functionality of Seal Strip Turbine Products

The primary function of seal strip turbine products is to enhance the efficiency of turbines by ensuring optimal sealing. In any turbine system, whether it be for electricity generation or propulsion, the presence of leaks can lead to significant energy losses. Seal strips help contain the working fluid—be it air, steam, or gas—within designated pathways, ensuring that the energy generated is maximized.

Moreover, these seals contribute to the longevity of the turbine. By effectively preventing contaminants from entering the system, seal strips protect vital components from wear and tear. This not only reduces maintenance costs but also extends the operational life of the turbine, resulting in higher overall productivity.

Applications of Seal Strip Turbine Products

Seal strip turbine products find extensive applications across various industries. In the power generation sector, they are commonly used in steam turbines, gas turbines, and wind turbines to enhance performance and reliability. In aerospace, seal strips are essential in jet engines, where they ensure optimal airflow and contribute to fuel efficiency.

seal strip turbine product

Additionally, seal strips play a crucial role in the manufacturing sector, particularly in compressors and industrial fans. These applications require precise sealing to maintain airflow and pressure, making seal strip products indispensable in ensuring operational effectiveness.

Advantages of Seal Strip Turbine Products

The adoption of seal strip turbine products offers several advantages. Firstly, they significantly contribute to energy efficiency by reducing leaks and ensuring that the working medium remains within the system. This is particularly important in the context of rising energy costs and the need for cleaner energy sources.

Secondly, these seals enhance safety. By preventing the accidental release of gases or fluids, seal strips mitigate the risk of hazardous situations, protecting both equipment and personnel.

Furthermore, seal strip turbine products are designed with ease of installation and maintenance in mind. Their customizable nature allows engineers to select the appropriate seal based on specific operational requirements, thus improving system performance without the need for extensive modifications.

Conclusion

In conclusion, seal strip turbine products are vital components in various mechanical systems, playing a crucial role in enhancing efficiency, safety, and longevity. As industries continue to strive for improved energy management and sustainability, the importance of these sealing technologies will only grow. Investing in high-quality seal strip turbine products will not only yield immediate benefits in terms of operational efficiency but will also contribute to a more sustainable future in energy generation and engineering.

With ongoing advancements in materials and design, the potential for further innovations in seal strip technology is vast, paving the way for more efficient and reliable turbine systems in the years to come.

-

Replacement Filter Screen for Karcher SE3001 SE2001 Vacuum

NewsAug.04,2025

-

Karcher A2004 Vacuum Cartridge Filter Replacement - Durable & Efficient

NewsAug.03,2025

-

Karcher WD/MV HEPA Cartridge Filters | Dust Control Experts

NewsAug.02,2025

-

Top Window Seal Strip Adhesive Companies | Strong Weatherproofing

NewsAug.01,2025

-

Premium Oil Filter for Can-Am Outlander 2003-2017 420256188

NewsJul.31,2025

-

Hightech Injection LED Module size6414: Premium LED Lighting

NewsJul.31,2025