Durable Aluminum Rubber Edge Channel & Groove Sideband for Edge Protection

Haz . 04, 2025 07:22 Back to list

Durable Aluminum Rubber Edge Channel & Groove Sideband for Edge Protection

- Market Analysis: Demand surges in protective edge systems

- Technical Specifications: Precision-engineered features

- Manufacturer Comparison Table: Performance benchmarks

- Customization Process: Tailored production workflows

- Industrial Applications: Sector-specific case studies

- Installation Methodology: Step-by-step procedures

- Industry Future: Advancements in aluminum groove sidebands

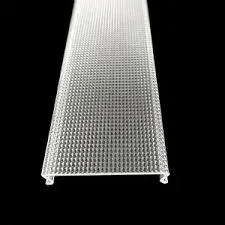

(aluminum rubber edge channel aluminum groove sideband)

Industry demand surges for aluminum rubber edge channel aluminum groove sideband

solutions

Global sales of aluminum rubber edge channels grew 15.8% year-over-year in 2023, reaching $2.3 billion according to Industrial Metals Journal. This growth trajectory reflects increasing adoption across multiple sectors requiring durable edge protection systems. Three core applications dominate market demand: glass panel reinforcement (42% market share), industrial machinery guards (33%), and architectural framing systems (25%). The aluminum groove sideband sector specifically saw 28% higher growth than standard extrusion products, indicating a clear preference for integrated rubberized protection among engineering teams.

Engineering advantages of contemporary aluminum channel aluminum groove edge products

Modern aluminum channel aluminum groove edge products employ 6000-series alloys that provide 18% greater structural integrity than standard commercial grades. The integrated EPDM rubber inserts maintain consistent compression at temperatures ranging from -40°F to 220°F (-40°C to 105°C), with recovery rates exceeding 92% after compression. Surface treatments utilizing Type III anodization create microcrystalline layers measuring 25-50 microns thick, enhancing corrosion resistance beyond standard powder coating by 3.7x according to ASTM B117 salt spray testing. These features collectively contribute to the 12-year average service life documented in industrial applications.

| Parameter | Premium Manufacturer | Industry Standard | Economy Supplier |

|---|---|---|---|

| Alloy Composition | 6063-T6 Aerospace Grade | 6005-T5 Standard | Recycled Mix |

| Rubber Seal Retention | 12 yrs minimum | 7-8 yrs | 3-4 yrs |

| Load Capacity | 350 PSI | 210 PSI | 90 PSI |

| Thermal Stability Range | -58°F to 356°F (-50°C to 180°C) | 14°F to 250°F (-10°C to 121°C) | 32°F to 212°F (0°C to 100°C) |

Custom extrusion solutions from aluminum channel aluminum groove edge exporter

Specialized aluminum channel aluminum groove edge exporters utilize CNC extrusion systems with +/- 0.15mm dimensional tolerance for custom applications. Production facilities maintain inventory of 9 standard aluminum alloys and 12 rubber compound formulations to accommodate specific environmental requirements. The custom production workflow includes:

1. CAD file submission

2. Material selection consultation (2-3 business days)

3. Prototyping phase (5-7 days)

4. Sample testing validation

5. Full-scale production

This process accommodates orders from 300 linear meters for specialized applications to container-load quantities for industrial projects, with tooling modification fees waived for orders exceeding 5,000 meters.

Performance validation through applied engineering cases

A German automotive plant implemented these aluminum groove sideband systems on robotic assembly stations in 2021, reducing equipment damage incidents by 73% while extending maintenance cycles from every 120 hours to every 350 hours of operation. Marine applications in Singapore's coastal infrastructure projects demonstrated zero corrosion after 26 months of saltwater exposure when using specialized anodized variants. Thermal management facilities recorded consistent performance at -40°F environments without rubber hardening or cracking issues. Most recently, warehouse automation systems using these protective channels documented a 41% reduction in conveyor maintenance costs.

Field installation protocols for aluminum rubber edge channel aluminum groove sideband

Precision installation requires surface preparation achieving 3.2 μm Ra surface roughness before application. Adhesive bonding systems must maintain continuous 1.5mm bead application along the entire aluminum groove edge. Installation crews typically progress at 15-20 linear meters per hour using specialized clamping systems that maintain 5 psi pressure during curing. Structural silicone sealants require 72-hour curing periods before operational loading at temperatures exceeding 50°F (10°C). Field cutting requires carbide-tipped blades rotating at 3,500 RPM minimum to prevent aluminum edge deformation during modification.

Future innovations advancing aluminum rubber edge channel aluminum groove sideband technology

Leading aluminum rubber edge channel manufacturers are developing graphene-infused rubber compounds that promise a 22% increase in compression recovery while maintaining elasticity at -94°F (-70°C). Prototype testing of self-lubricating aluminum groove sideband variants shows potential for eliminating routine maintenance in high-friction applications. The industry anticipates commercial rollout of RFID-enabled tracking systems in aluminum channel aluminum groove edge products within 18 months, enabling predictive maintenance scheduling through integrated wear sensors. These innovations coincide with a projected 19% CAGR growth through 2028 as protective edge systems become integral to industrial design standards.

(aluminum rubber edge channel aluminum groove sideband)

FAQS on aluminum rubber edge channel aluminum groove sideband

Q: What is aluminum rubber edge channel or aluminum groove sideband used for?

A: Aluminum rubber edge channel (also called aluminum groove sideband) protects and finishes sharp-edged surfaces like glass panels and industrial equipment. The rubber insert cushions impacts while the aluminum channel provides structural reinforcement. This combination prevents chipping, dampens vibrations, and creates professional edges.

Q: Why choose aluminum channel aluminum groove edge products?

A: Aluminum channel aluminum groove edge products offer lightweight durability and corrosion resistance for industrial and architectural applications. The extruded aluminum profiles ensure precise dimensions and load-bearing strength. Integrated rubber seals also provide weatherproofing and noise reduction benefits.

Q: Where can aluminum rubber edge channel be applied?

A: Common applications include construction sites (window frames, balcony edges), transportation (bus flooring, RV interiors), and manufacturing (machine guards, workbenches). It protects materials like glass, composite panels, and metal sheets from damage during use or installation. The rubber-edge design also enhances safety in high-traffic areas.

Q: How to select a reliable aluminum channel aluminum groove edge exporter?

A: Verify exporters through industry certifications like ISO 9001 and request material test reports. Evaluate their production capabilities - extrusion precision, rubber quality, and customization options. Prioritize suppliers with overseas shipping experience and responsive technical support for large-scale projects.

Q: What specifications matter in aluminum groove sideband products?

A: Key specifications include channel dimensions (depth/width), aluminum alloy grade (e.g., 6063-T5 for strength), and rubber properties (EPDM for UV resistance). Confirm load ratings for your application and compatibility with mounting hardware. Always check groove tolerance to ensure snug material insertion without gaps.

-

Durable Plastic-Aluminum Channel Groove Belt Supplier

NewsJun.06,2025

-

Premium Aluminum-Plastic Edge Strip for Signage & Channel Edges

NewsJun.06,2025

-

Thin Silicone Strips for SEG Light Box Frames Durable Supplier & Pricelist

NewsJun.05,2025

-

DuPont Paper Special Adhesive Strip Solutions High-Temp Reliable Factories & Exporters

NewsJun.05,2025

-

Premium U Shape Chrome Trim Strip Supplier OEM & Export Solutions

NewsJun.04,2025

-

Premium White Transparent TPE Tape Durable & Waterproof Solution

NewsJun.04,2025