Manufacturing Facility for Screen Seal Strips with Quality Assurance and Efficiency

Nov . 09, 2024 23:22 Back to list

Manufacturing Facility for Screen Seal Strips with Quality Assurance and Efficiency

The Importance of Screen Seal Strips A Comprehensive Overview of the Factory Production Process

In the world of construction and home improvement, screen seal strips play a crucial role in enhancing the functionality and durability of various structures. These simple yet effective components are essential for creating airtight and watertight seals around windows, doors, and screens, offering protection against external elements while improving energy efficiency. This article delves into the intricacies of the screen seal strip factory, highlighting the production process, materials used, and the significance of quality control.

Understanding Screen Seal Strips

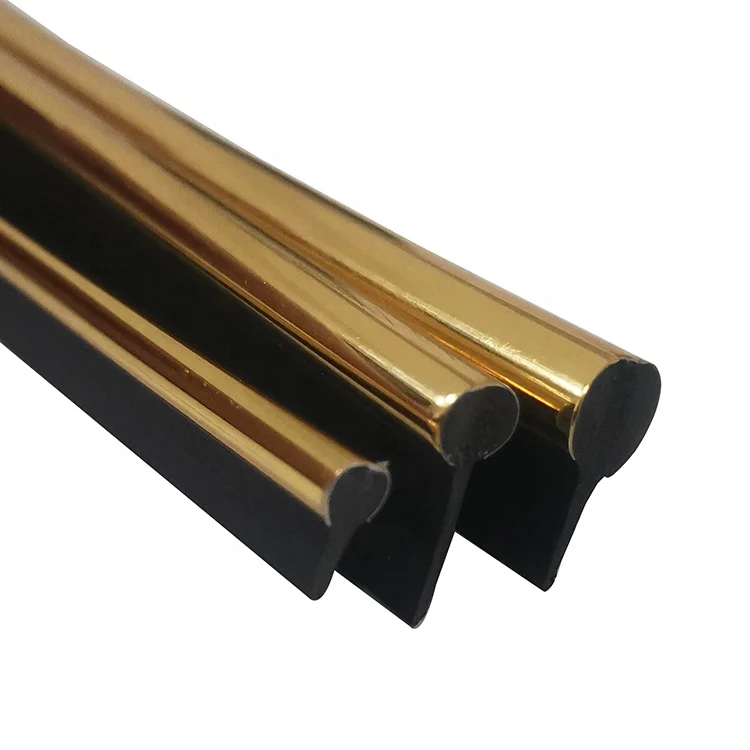

Screen seal strips are typically made from durable, weather-resistant materials designed to withstand the test of time. Common materials include rubber, silicone, and foam, each offering specific benefits such as flexibility, insulation, and resistance to environmental conditions. These strips are primarily used in residential and commercial buildings, ensuring that screens fit snugly and maintain their integrity against drafts, water leaks, and insect invasions.

Raw Materials and Sourcing

The journey of a screen seal strip begins with the careful selection of raw materials. Factories often source high-quality materials from reputable suppliers to ensure the finished product meets industry standards. For instance, rubber seals can be derived from natural rubber or synthetic alternatives, depending on the desired properties. Silicone, known for its flexibility and resilience, is another popular choice, especially in environments that face extreme temperatures or humidity. Foam is often used for its lightweight and compressible nature, allowing for easy installation and effective sealing.

Manufacturing Process

Once materials are sourced, the manufacturing process kicks into gear. The production of screen seal strips typically involves several key steps

1. Material Preparation The raw materials are processed and prepared for shaping. This may include mixing compounds, heating materials, or cutting them into required dimensions. 2. Extrusion One of the most common methods to create seal strips is through extrusion, where heated material is forced through a die to create continuous profiles of the desired shape. This step is crucial as it determines the final dimensions and properties of the seal strip.

screen seal strip factory

3. Molding In addition to extrusion, molding techniques may be used, especially for specialized shapes or designs. This involves pouring liquid material into a mold and allowing it to cure, forming the desired product.

4. Cutting and Finishing After extrusion or molding, the strips are cut to specific lengths. Quality checks are conducted at this stage to ensure precision and adherence to specifications. Additional finishing processes may include surface treatment or coating to enhance durability and aesthetics.

5. Quality Control A vital aspect of the manufacturing process, quality control ensures that each batch of seal strips meets rigorous standards. Tests are conducted to assess their flexibility, strength, and resistance to environmental factors. This step is crucial to maintain the factory's reputation and to ensure customer satisfaction.

Packaging and Distribution

Once the screen seal strips pass quality control, they are packaged for distribution. Factories often use biodegradable or recyclable materials for packaging to align with sustainability efforts in the industry. Efficient distribution channels are established to ensure that these products reach retailers, builders, and consumers promptly.

The Role of Innovation

As demands evolve, screen seal strip factories continually explore innovative techniques and materials to enhance product performance. Research and development play a key role in this process, leading to improvements in energy efficiency and weather resistance. Moreover, automation and advanced manufacturing technologies are increasingly utilized to streamline production and reduce costs.

Conclusion

In summary, screen seal strip factories are integral to providing high-quality sealing solutions for various applications. From the careful selection of materials to the meticulous manufacturing process and stringent quality control, every aspect of production contributes to the overall efficacy of the final product. As the market grows and technology advances, these factories remain at the forefront of innovation, meeting the ever-changing needs of consumers and industries alike. The importance of screen seal strips cannot be overstated, as they contribute significantly to energy efficiency, comfort, and protection in our living and working spaces.

-

Premium Car Trim Strip - Top Car Moulding Trim Strip Exporters & 3 Car Moldings Manufacturers

NewsJul.08,2025

-

High-Quality Sponge Seal Solutions Leading Sponge Door Seal Manufacturer & Service

NewsJul.08,2025

-

U Shape Chrome Trim Strip Manufacturer & Exporter High-Quality Factory Products

NewsJul.07,2025

-

High-Quality LED Neon Light Supplier – Flexible & Color Changing Neon Strip Lights for Versatile Applications

NewsJul.07,2025

-

High-Quality White Transparent Silicone Strip Reliable Exporter & Factory Price

NewsJul.07,2025

-

Premium U Shape Chrome Trim Strip – Reliable Factory & Exporter for Automotive & Home Décor

NewsJul.06,2025