Acrylic Heat Bender Tool-Type A-Hebei Pulongte Rubber and Plastic Technology Co., Ltd.|Precision Manufacturing&Ergonomic Design

Sep . 12, 2025 05:25 Back to list

Acrylic Heat Bender Tool-Type A-Hebei Pulongte Rubber and Plastic Technology Co., Ltd.|Precision Manufacturing&Ergonomic Design

The Acrylic Heat Bender Tool-Type A represents a breakthrough in precision manufacturing, offering unparalleled control over acrylic material shaping. Designed for industrial and artisanal applications, this tool combines ergonomic design with cutting-edge technology to meet the demands of modern fabrication. Below, we explore its features, technical specifications, and the company behind its innovation.

Image 1: Light Cover Acrylic Lampshade - Demonstrating the versatility of acrylic materials in design applications.

Product Overview

The Acrylic Heat Bender Tool-Type A is engineered to simplify the process of bending acrylic sheets into complex shapes. Unlike traditional methods that rely on manual heating and bending, this tool ensures consistent results with minimal effort. Its design caters to both small-scale workshops and large-scale manufacturing facilities, making it a versatile solution for industries ranging from signage to automotive components.

Key features include:

- Uniform heat distribution for precise bending

- Ergonomic handle for user comfort

- Durable construction for long-term use

- Compatibility with various acrylic thicknesses

Image 2: 3D Metal Acrylic Trim Cap - Highlighting the tool's ability to create intricate designs.

Technical Specifications

| Parameter | Details |

|---|---|

| Material | High-grade aluminum alloy |

| Heating Element | Electric resistance with adjustable temperature control |

| Operating Temperature Range | 100°C - 200°C |

| Power Supply | 110V/220V AC, 50/60Hz |

| Weight | 1.8 kg |

| Dimensions | 300mm (L) x 150mm (W) x 100mm (H) |

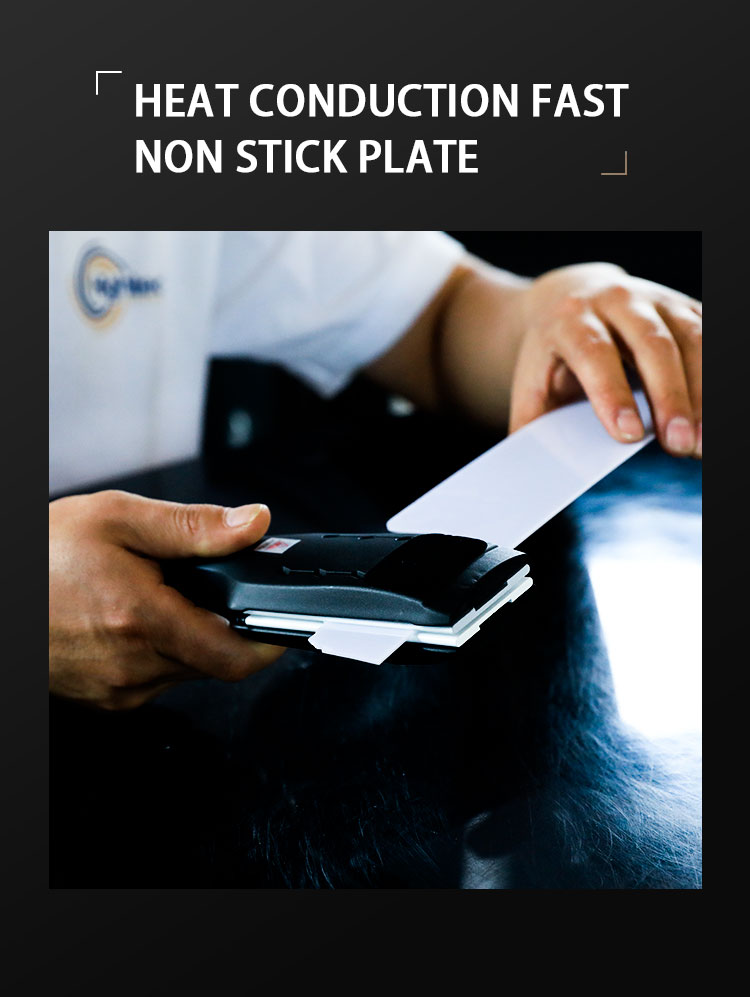

Image 3: Acrylic Heat Bender Tool-Type A - Visual representation of the tool's design and functionality.

Applications and Use Cases

The Acrylic Heat Bender Tool-Type A is ideal for applications requiring precise acrylic shaping, including:

- Signage and Displays: Creating custom-shaped signs, LED panels, and light boxes.

- Automotive Industry: Manufacturing dashboards, trim components, and interior panels.

- Architectural Design: Producing curved acrylic panels for partitions, ceilings, and decorative elements.

- Consumer Goods: Fabricating product casings, lampshades, and packaging.

Image 4: Acrylic Heat Bender Tool-Type A Exporter - Highlighting the tool's global reach and industrial applications.

Company Background: Hebei Pulongte Rubber and Plastic Technology Co., Ltd.

Founded in 2010, Hebei Pulongte Rubber and Plastic Technology Co., Ltd. is a leading manufacturer of specialized industrial tools and materials. The company's commitment to innovation and quality has established it as a trusted supplier in the global market. With a focus on research and development, Hebei Pulongte continues to push the boundaries of material science and manufacturing technology.

Key aspects of the company's operations include:

- Advanced production facilities equipped with state-of-the-art machinery

- Comprehensive quality control systems aligned with international standards

- Customized solutions for diverse industries

- Global distribution network with exports to over 50 countries

Image 5: Hebei Pulongte Rubber and Plastic Technology Co., Ltd. - The company's dedication to innovation and quality.

Why Choose the Acrylic Heat Bender Tool-Type A?

The Acrylic Heat Bender Tool-Type A stands out due to its combination of precision, durability, and user-friendly design. Unlike traditional methods that often result in uneven bends or material damage, this tool ensures consistent results with minimal effort. Its adjustable temperature control allows for optimal performance across different acrylic thicknesses, while the ergonomic handle reduces user fatigue during extended use.

Moreover, the tool's compatibility with a wide range of acrylic materials makes it a versatile choice for both prototyping and mass production. Whether you're creating intricate designs for architectural projects or manufacturing automotive components, the Acrylic Heat Bender Tool-Type A delivers the reliability and precision required for industrial-grade results.

Image 6: Acrylic Heat Bender Tool-Type A Supplier - Ensuring quality and reliability in every product.

Industry Standards and Certifications

Hebei Pulongte adheres to stringent industry standards to ensure the safety and performance of its products. The Acrylic Heat Bender Tool-Type A complies with NIST guidelines for precision manufacturing, reflecting the company's commitment to excellence. According to NIST, "Accurate measurements and adherence to technical standards are critical for ensuring the reliability and interoperability of industrial tools" (NIST, 2025).

Additionally, the tool meets international safety certifications, including ISO 9001 and CE, ensuring compliance with global regulatory requirements. These certifications underscore Hebei Pulongte's dedication to delivering products that meet the highest standards of quality and safety.

Image 7: 3D Metal Acrylic Trim Cap - Demonstrating the tool's capability to create complex shapes.

Conclusion

The Acrylic Heat Bender Tool-Type A is a testament to the synergy of innovation and engineering excellence. With its advanced features, precise control, and robust design, this tool is an indispensable asset for any acrylic fabrication process. Backed by the expertise of Hebei Pulongte Rubber and Plastic Technology Co., Ltd., the product exemplifies the company's commitment to delivering high-quality solutions that meet the evolving needs of modern industries.

For more information on the Acrylic Heat Bender Tool-Type A or to explore other products from Hebei Pulongte, visit their official website or contact their sales team directly.

Image 8: 3D Metal Acrylic Trim Cap - Highlighting the tool's role in creating detailed acrylic components.

References

NIST. (2025). Standards for Precision Manufacturing. Retrieved from https://www.nist.gov

-

Comprehensive Guide to White PVC Material: Benefits, Applications & Innovations

NewsNov.24,2025

-

Flat Hard Plastic PP Flexible Strips: Durable, Flexible, and Sustainable Solutions for Modern Industry

NewsNov.24,2025

-

Understanding Soft PVC Slip Cover Tuck Grip – Global Uses & Benefits

NewsNov.23,2025

-

Discover the Practical Benefits and Global Use of Square Plastic Tubes

NewsNov.23,2025

-

Understanding Led Lampshade Diffuser PC Covers – Benefits, Trends & Buying Guide

NewsNov.22,2025

-

Durable, Cost-Effective PVC Rectangular Grey Tube for Frame Solutions | Pulongte

NewsNov.22,2025