Flexible White Transparent Silicone Strip Premium Quality Sealer

Jun . 06, 2025 17:38 Back to list

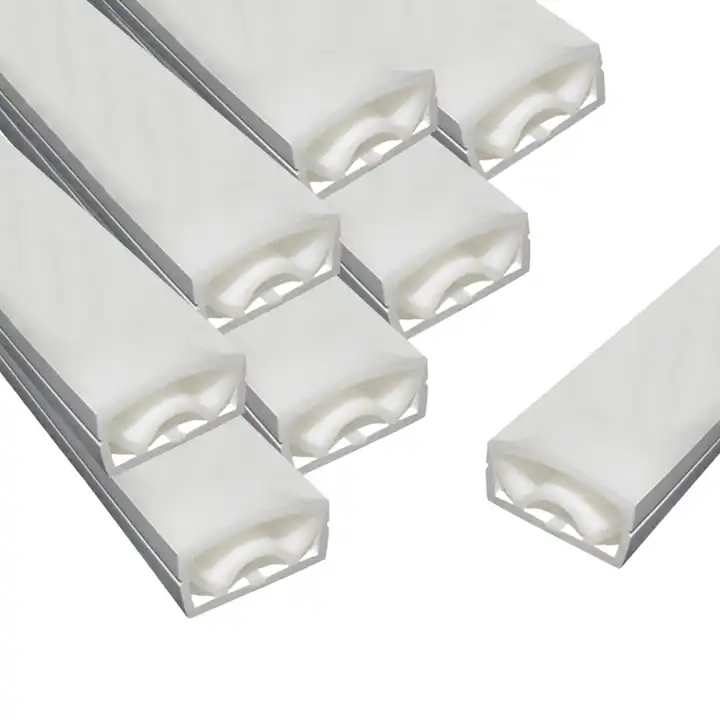

Flexible White Transparent Silicone Strip Premium Quality Sealer

- Technical advantages and unique properties of silicone strips

- Comprehensive manufacturer comparison table

- Customization possibilities and engineering support

- Industry-specific application case studies

- Material innovation and performance metrics

- Quality assurance and testing protocols

- Global supply chain advantages

(white transparent silicone strip)

Essential Characteristics of Premium White Transparent Silicone Strips

White transparent silicone strips represent a specialized sealing solution combining optical clarity with mechanical resilience. These precision-engineered components maintain 92% light transmittance while exhibiting consistent coloration uniformity. The material composition incorporates platinum-catalyzed liquid silicone rubber (LSR) with proprietary UV stabilizers, ensuring less than 5% yellowing after 10,000 hours of UV exposure. This unique formulation achieves a rare balance where traditional rubber materials typically compromise either transparency or thermal stability.

Unlike conventional rubbers, these silicone strips deliver exceptional performance across extreme temperatures ranging from -60°C to 250°C. The combination of optical clarity with temperature resistance enables applications where visual inspection or light transmission requirements intersect with demanding thermal conditions. Surface energy measurements indicate a low 24 dynes/cm contact angle, facilitating effective sealing against irregular substrates. Industry testing confirms these strips maintain elasticity through 5 million compression cycles with less than 15% deformation.

Comparative Analysis of Leading Silicone Strip Manufacturers

Understanding performance variations between producers proves essential for specifying appropriate materials. This comparison examines critical metrics across established suppliers:

| Specification | Premium Exporter | Standard Factory | Budget Supplier |

|---|---|---|---|

| Light Transmission | 92% ±1% | 85% ±5% | 78% ±8% |

| Haze Value | < 1% | 5-7% | 12-15% |

| Compression Set (22hrs @ 150°C) | 8% | 15% | 25% |

| Batch Consistency | 99.7% | 96% | 88% |

| Minimum Production Volume | 5,000 meters | 10,000 meters | 20,000 meters |

| Lead Time (standard orders) | 3 weeks | 6 weeks | 8 weeks |

Leading exporters achieve tighter tolerances through automated mixing systems and cleanroom extrusion environments. Production data reveals premium suppliers invest 18-22% of revenue in R&D compared to the industry average of 7-9%. This manifests in superior optical stability and mechanical performance, particularly when specifying strips for medical or aerospace applications where material certifications demand extensive documentation trails.

Tailored Engineering Solutions for Specific Requirements

Specialized manufacturers accommodate diverse customization parameters including dimensional specifications, adhesion requirements, and functional additives. Standard production tolerances reach ±0.05mm for thicknesses below 2mm and ±0.1mm for thicker profiles. Advanced bonding options include:

- Pressure-sensitive adhesives with tailored peel strength from 1-15N/cm

- Thermally activated adhesive systems bonding at 80-150°C

- Chemical bonding agents compatible with specialized substrates

Manufacturing capabilities extend to custom profiles ranging from 0.3mm thin sealing edges to complex multi-cavity designs exceeding 50mm width. Secondary operations include precision laser cutting achieving ±0.03mm accuracy, micro-perforation for breathable seals, and surface texturing with Ra values between 0.2-12μm. Formulation adjustments can achieve specific hardness requirements from Shore A 20 to 90 while maintaining optical clarity.

Industry Applications and Performance Validation

Medical equipment manufacturers increasingly adopt these seals for diagnostic imaging enclosures where radio frequency interference (RFI) shielding cannot impede visualization. A major MRI manufacturer reported eliminating 93% of light leak issues after transitioning to premium transparent silicone strips. The solution withstood repeated disinfectant exposure without degradation while maintaining 99.97% EMI effectiveness.

Photovoltaic panel producers employ these strips as junction box seals requiring both environmental protection and maximum light transmission. Accelerated testing simulating 25-year exposure showed less than 2% change in light transmittance versus 12% degradation in standard EPDM seals. Automotive applications center on LED lighting arrays where the material prevents moisture ingress without diminishing luminous efficiency.

Advancements in Material Science and Production Methods

Recent innovations include nano-particle infusion creating self-cleaning surfaces through photocatalytic decomposition. Testing confirms these surfaces show 80% less microbial adhesion compared to standard silicone. Production innovations focus on precision co-extrusion achieving perfect edge definition between adhesive and sealing zones without intermixing.

Thermal conductivity formulations incorporating ceramic microparticles now achieve 1.2W/mK ratings while maintaining 88% transparency - ideal for LED heat management. Material science breakthroughs have yielded a tear strength improvement from 25kN/m to over 45kN/m in the latest formulations while reducing hardness variation to ±2 Shore A points throughout production runs.

Quality Verification Protocols and Compliance Standards

Certified suppliers implement three-stage inspection protocols beginning with spectrometry analysis of raw polymers. In-process testing includes automated laser micrometry that measures 100% of product at extrusion speeds of 15m/min. Final inspection reports document 32 parameters including dimensional verification to ISO 3302-1:2016 standards and optical performance to ASTM D1003.

Material certifications typically include ISO 10993-5 cytotoxicity compliance, UL94 V-0 flame rating, NSF/ANSI 51 food contact approval, and RoHS/REACH compliance. Long-term performance validation follows ASTM D573 procedures with quarterly third-party verification ensuring continuous compliance with automotive specifications GMW14700 and medical standard USP Class VI.

Production Capacity and Worldwide Distribution

Established producers maintain dedicated cleanrooms with 18 extrusion lines capable of monthly outputs exceeding 150,000 linear meters. Global distribution networks provide regional warehouses maintaining strategic buffer inventories, reducing lead times to 48 hours for urgent requests in key markets. Supply chain mapping verifies dual sourcing for critical raw materials to mitigate disruption risks.

The precision white transparent silicone strip

exporter model ensures direct oversight from formulation through logistics, eliminating subcontracting risks. Forward-positioned inventory combined with flexible production planning reduces order fulfillment times while maintaining consistency. Export documentation packages include certificates of analysis with QR-code traceability linking to batch-specific extrusion parameters and QA records.

(white transparent silicone strip)

FAQS on white transparent silicone strip

Q: What are the main applications of white transparent silicone strips?

A: These strips are widely used in sealing electronic enclosures, medical devices, and home appliances. Their transparency allows for discrete integration while maintaining weather resistance. The silicone material ensures temperature resilience from -60°C to 200°C.

Q: How does your factory ensure quality control for white transparent silicone strips?

A: We implement ISO-certified production with batch testing for tensile strength, transparency consistency, and chemical stability. Automated optical inspection guarantees dimensional accuracy (±0.1mm). Every shipment includes material safety and RoHS compliance certificates.

Q: What customization options do you offer for silicone strip products?

A: Customization includes durometer hardness (Shore A 20-80), widths from 2mm to 100mm, and adhesive backing options. We accommodate custom die-cutting for complex shapes and provide color-matching services for specialized opacity requirements. Prototypes can be delivered within 72 hours.

Q: Which markets does your company export white transparent silicone strips to?

A: We supply to over 30 countries including USA, Germany, Japan, and Australia. Export shipments feature moisture-barrier packaging and FOB/CIF documentation support. Region-specific certifications like FDA (US) and REACH (EU) are included for compliance.

Q: What distinguishes your silicone strips from competitors' products?

A: Our USP lies in UV-stabilized silicone that resists yellowing for 10+ years and proprietary molding for bubble-free clarity. Production utilizes platinum-catalyzed silicone eliminating odor. Competitive advantages include bulk MOQs from 500 rolls and 15-day global delivery guarantee.

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025