Acrylic Heat Bender Tool-Type A - Hebei Pulongte | Precision Bending, Industrial Efficiency

Sep . 11, 2025 05:25 Back to list

Acrylic Heat Bender Tool-Type A - Hebei Pulongte | Precision Bending, Industrial Efficiency

The Acrylic Heat Bender Tool-Type A represents a significant advancement in acrylic manufacturing, offering precision, efficiency, and versatility for industries ranging from lighting design to architectural applications. Developed by Hebei Pulongte Rubber and Plastic Technology Co., Ltd., this tool exemplifies the synergy between innovation and practicality in modern industrial solutions. This article explores the product’s features, advantages, technical specifications, and its role in shaping the future of acrylic fabrication.

Product Overview: A Tool Designed for Precision and Versatility

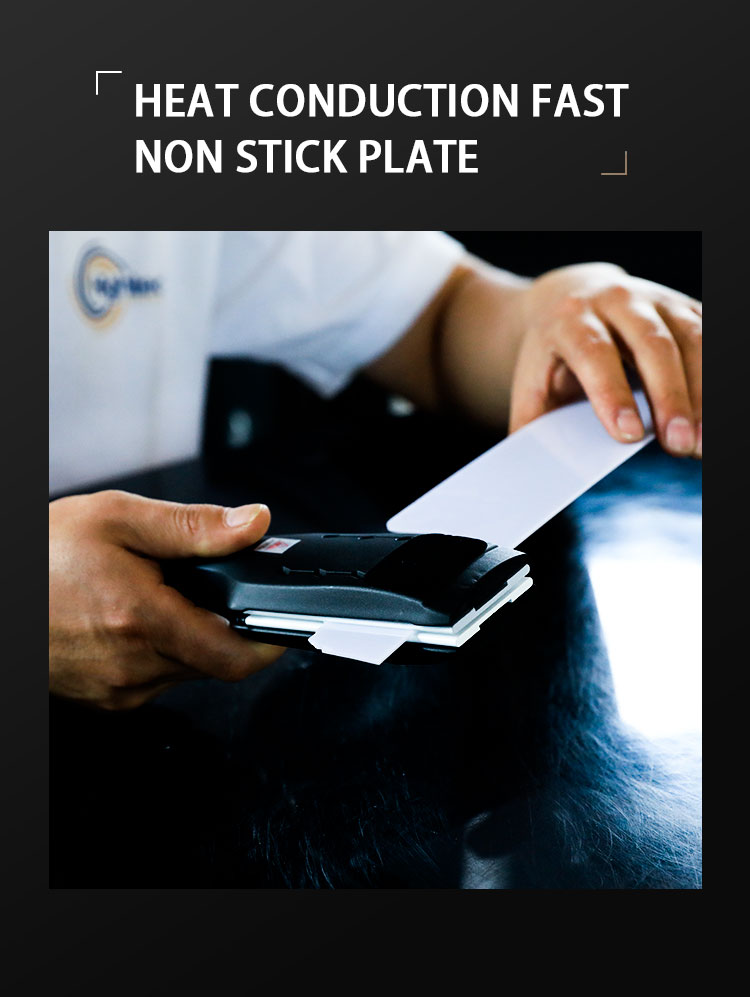

The Acrylic Heat Bender Tool-Type A is engineered to simplify the process of bending acrylic sheets into complex shapes, ensuring accuracy and consistency. Whether for crafting intricate lampshades, decorative trim caps, or custom architectural components, this tool caters to a wide array of applications. Its design emphasizes user-friendly operation, durability, and adaptability to different acrylic thicknesses and shapes.

Key features of the tool include:

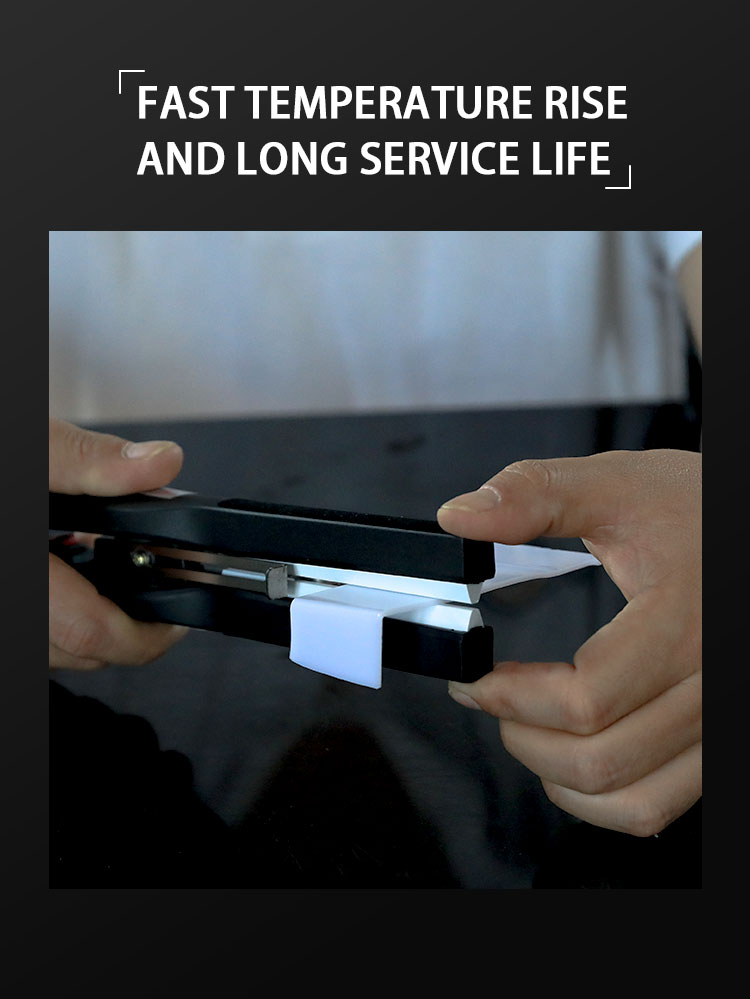

- High-Temperature Resistance: The tool is equipped with a heating element capable of reaching optimal temperatures for acrylic bending without compromising material integrity.

- Adjustable Bending Mechanism: Allows users to customize the bending angle and curvature, accommodating diverse design requirements.

- Durable Construction: Built with high-quality materials to withstand prolonged use in industrial environments.

Advantages: Enhancing Efficiency and Quality in Acrylic Fabrication

The Acrylic Heat Bender Tool-Type A stands out for its ability to streamline the acrylic bending process, reducing both time and labor costs. By eliminating the need for manual heating and bending, the tool ensures uniform results, minimizing material waste and rework. This is particularly beneficial for manufacturers and artisans who prioritize precision and consistency.

Additional advantages include:

- Cost-Effectiveness: The tool’s efficiency translates to lower production costs, making it an attractive option for small to large-scale operations.

- Easy Maintenance: The tool’s design facilitates straightforward cleaning and upkeep, ensuring long-term performance.

- Wide Application Scope: From creating custom lampshades to producing industrial components, the tool’s adaptability makes it a valuable asset across multiple sectors.

Technical Specifications: A Closer Look at Performance and Design

The Acrylic Heat Bender Tool-Type A is designed to meet the demands of modern manufacturing. Below is a detailed specification table outlining its key parameters:

| Parameter | Details |

|---|---|

| Heating Element | High-efficiency electric heating coil |

| Temperature Range | 150°C–250°C (adjustable) |

| Material Compatibility | Acrylic sheets (thickness: 1–6 mm) |

| Dimensions | 450mm x 300mm x 200mm |

| Power Supply | 220V/50Hz |

| Weight | 8.5 kg |

Applications: Transforming Industries with Acrylic Innovation

The Acrylic Heat Bender Tool-Type A is a versatile solution for industries that rely on acrylic materials. Its applications span across various sectors, including:

- Lighting Industry: Ideal for crafting intricate lampshades and diffusers, enhancing the aesthetic and functional aspects of lighting fixtures.

- Architectural Design: Enables the creation of curved acrylic panels and decorative elements for modern buildings and interiors.

- Consumer Goods: Used in the production of custom-shaped acrylic products such as trim caps, signage, and display cases.

- Industrial Manufacturing: Supports the fabrication of components for machinery, automotive, and aerospace industries.

Company Background: Hebei Pulongte Rubber and Plastic Technology Co., Ltd.

As the manufacturer of the Acrylic Heat Bender Tool-Type A, Hebei Pulongte Rubber and Plastic Technology Co., Ltd. has established itself as a leader in the production of industrial tools and materials. Located in Hebei, China, the company specializes in providing innovative solutions for the plastics and rubber industries. With a focus on quality, precision, and customer satisfaction, Hebei Pulongte has built a reputation for delivering reliable products that meet global standards.

The company’s commitment to technological advancement is evident in its product lineup, which includes a wide range of tools and materials designed to enhance manufacturing efficiency. By leveraging cutting-edge technology and rigorous quality control processes, Hebei Pulongte ensures that its products, such as the Acrylic Heat Bender Tool-Type A, meet the highest standards of performance and durability.

Industry Standards and Compliance: A Commitment to Excellence

The Acrylic Heat Bender Tool-Type A adheres to international industry standards, ensuring safety, efficiency, and reliability. While specific certifications are not detailed in the provided context, the tool’s design and functionality align with the principles of precision engineering, as emphasized by organizations like the National Institute of Standards and Technology (NIST). NIST plays a critical role in developing measurement standards that underpin technological innovation, and its guidelines are often referenced by manufacturers to ensure product quality and consistency.

According to NIST’s mission to "advance technology for the public good," tools like the Acrylic Heat Bender Tool-Type A exemplify the importance of precise measurement and reliable performance in industrial applications. By adhering to such standards, Hebei Pulongte ensures that its products contribute to the broader goal of technological advancement and economic growth.

Conclusion: A Tool for the Future of Acrylic Manufacturing

The Acrylic Heat Bender Tool-Type A is more than just a manufacturing tool—it is a testament to the power of innovation and precision in the plastics industry. By combining advanced technology with user-centric design, this tool empowers manufacturers and artisans to achieve exceptional results with minimal effort. Its versatility, durability, and alignment with industry standards make it an indispensable asset for businesses seeking to enhance their acrylic fabrication capabilities.

For those interested in learning more about the Acrylic Heat Bender Tool-Type A or exploring the full range of products offered by Hebei Pulongte Rubber and Plastic Technology Co., Ltd., visiting the company’s official website is highly recommended. With a commitment to quality and innovation, Hebei Pulongte continues to drive progress in the industrial tools and materials sector.

References

National Institute of Standards and Technology (NIST). (n.d.). Driving Innovation. Retrieved from https://www.nist.gov/

Hebei Pulongte Rubber and Plastic Technology Co., Ltd.. (n.d.). Acrylic Heat Bender Tool-Type A. Retrieved from https://www.pulongte.com/acrylic-heat-bender-tool-type-a.html

-

Comprehensive Guide to White PVC Material: Benefits, Applications & Innovations

NewsNov.24,2025

-

Flat Hard Plastic PP Flexible Strips: Durable, Flexible, and Sustainable Solutions for Modern Industry

NewsNov.24,2025

-

Understanding Soft PVC Slip Cover Tuck Grip – Global Uses & Benefits

NewsNov.23,2025

-

Discover the Practical Benefits and Global Use of Square Plastic Tubes

NewsNov.23,2025

-

Understanding Led Lampshade Diffuser PC Covers – Benefits, Trends & Buying Guide

NewsNov.22,2025

-

Durable, Cost-Effective PVC Rectangular Grey Tube for Frame Solutions | Pulongte

NewsNov.22,2025