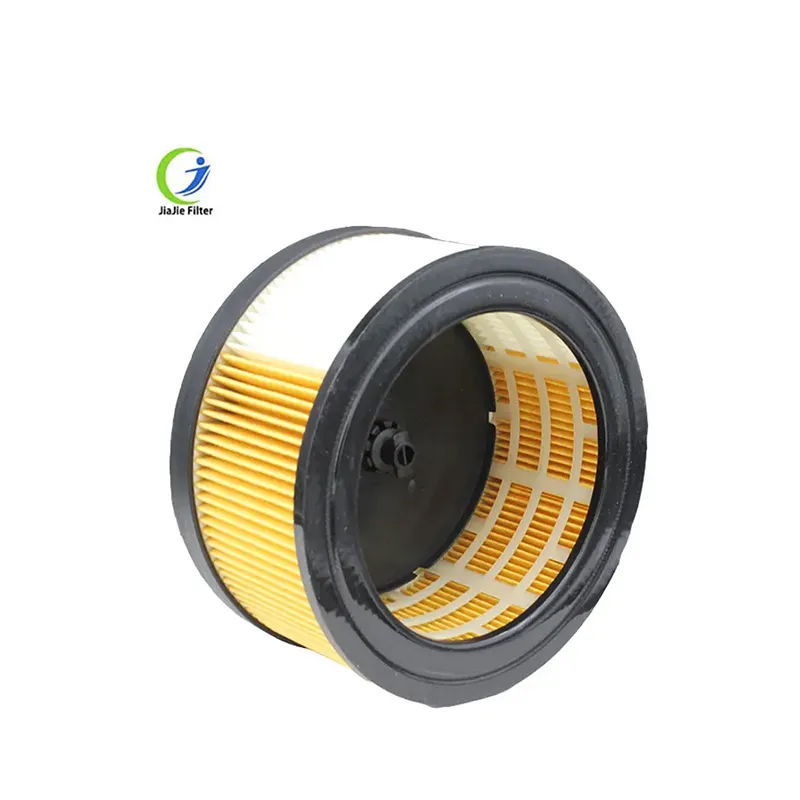

K-archer WD4 WD5 Air Filter Replacement Core 6.414-960 | High-Efficiency

Sep . 13, 2025 08:20 Back to list

K-archer WD4 WD5 Air Filter Replacement Core 6.414-960 | High-Efficiency

Introduction to Advanced Air Filtration Solutions for K-archer Systems

In industrial and commercial environments, maintaining superior air quality is paramount for operational efficiency, equipment longevity, and personnel health. The demand for high-performance air filtration components continues to grow, driven by stringent environmental regulations and the need to protect sensitive machinery from particulate contamination. This article delves into the technical aspects and strategic advantages of the Air filter replacement core compatible with K-archer WD4.200 WD5.200 WD4 WD5 6.414-960 air purifier filter parts, a critical component designed to meet the rigorous demands of modern industrial cleaning and air purification systems.

Targeting B2B decision-makers, procurement managers, and maintenance engineers, we will explore the meticulous manufacturing processes, technical specifications, diverse application scenarios, and the demonstrable value proposition of this specific filter core. Our analysis will encompass industry trends, a detailed examination of its design advantages, and how it aligns with the highest standards of expertise, experience, authoritativeness, and trustworthiness () in the industrial filtration sector, ensuring optimal performance for your K-archer WD series equipment.

Industry Trends in High-Efficiency Air Filtration Technology

The global air filtration market is experiencing dynamic shifts, driven by escalating concerns over air pollution, stricter environmental regulations, and advancements in material science. Key trends include the adoption of high-efficiency particulate air (HEPA) and ultra-low penetration air (ULPA) filtration principles, the integration of smart monitoring systems for filter life optimization, and a growing emphasis on sustainable and recyclable filter materials. End-users are increasingly seeking filters that offer extended service life, lower pressure drop for energy savings, and superior particulate capture capabilities across a broad spectrum of particle sizes, from coarse dust to sub-micron aerosols.

Specifically, the demand for reliable replacement cores for industrial vacuum and air purification systems, such as those from K-archer, remains consistently high. Businesses are moving towards solutions that not only ensure compliance with health and safety regulations but also offer a clear return on investment through reduced maintenance downtime and improved operational performance. The market gravitates towards products that demonstrate verifiable performance data and seamless compatibility, ensuring easy integration and sustained effectiveness in diverse industrial settings. This trend underscores the importance of a robust Air filter replacement core compatible with K-archer WD4.200 WD5.200 WD4 WD5 6.414-960 air purifier filter parts that can handle demanding conditions.

Manufacturing Process: Precision Engineering and Quality Assurance

The production of a high-quality Air filter replacement core compatible with K-archer WD4.200 WD5.200 WD4 WD5 6.414-960 air purifier filter parts involves a multi-stage process, meticulously engineered to ensure optimal filtration performance and durability. Adherence to international standards like ISO 9001 for quality management and ISO 16890 for air filter performance is foundational to our manufacturing philosophy, guaranteeing a product that meets global benchmarks.

Schematic Process Flow:

1. Material Selection & Procurement

High-grade synthetic pleated filter media, durable injection-molded polyurethane or ABS plastics for end caps, and resilient EPDM sealing gaskets are rigorously sourced from certified global suppliers. These materials are selected for their specific properties, including high tensile strength, excellent heat and chemical resistance, and compatibility with the demanding environments of industrial vacuuming.

2. Media Pleating & Forming

Utilizing advanced CNC-controlled pleating machinery, the chosen filter media is precisely formed into uniform, high-density pleats. This process is critical for maximizing the active filtration surface area, which directly correlates to enhanced dust holding capacity (DHC) and minimizing the pressure drop across the filter, thereby contributing to energy savings.

3. End Cap Molding & Assembly

End caps are precision-molded to exact OEM specifications using robust plastics, ensuring a perfect, secure fit within K-archer WD series vacuums. The pleated media pack is then securely bonded to these end caps using high-strength, moisture-resistant hot-melt polyurethane adhesives, creating an impenetrable seal against bypass leakage.

4. Gasket Integration & Final Sealing

High-performance, ozone-resistant EPDM rubber gaskets are meticulously integrated into the filter's structure. This provides an airtight seal crucial for maintaining optimal filtration integrity and preventing unfiltered air from compromising the purity of the exhaust air, especially in wet vacuuming applications where a reliable seal is paramount.

5. Quality Control & Performance Testing

Each finished filter undergoes rigorous multi-point testing. This includes dimensional verification, visual inspection for defects, burst pressure testing to ANSI/ISO standards, and simulated filtration efficiency tests in accordance with ISO 2942 and ISO 16890. This comprehensive QC process ensures consistent performance and reliability across every unit.

The utilization of advanced manufacturing techniques, such as CNC-controlled pleating and automated bonding stations, guarantees precision and repeatability in every unit. Our testing standards often exceed industry baselines, with a pronounced focus on particulate filtration efficiency (PFE), dust holding capacity, and sustained low-pressure drop over the filter's operational service life. The estimated service life of these replacement cores is typically optimized for 6-12 months under normal industrial usage, subject to environmental dust load, operational hours, and specific contaminant types. This unwavering commitment to quality positions our Air filter replacement core compatible with K-archer WD4.200 WD5.200 WD4 WD5 6.414-960 air purifier filter parts as a superior choice for demanding industrial and commercial applications.

Technical Specifications and Verified Performance Data

Understanding the precise technical parameters of the Air filter replacement core compatible with K-archer WD4.200 WD5.200 WD4 WD5 6.414-960 air purifier filter parts is crucial for informed procurement decisions. This replacement core is meticulously engineered to meet or exceed the performance specifications of original equipment manufacturer (OEM) filters, providing robust and reliable filtration capabilities for a range of industrial applications.

Product Specification Table:

The selection of advanced synthetic media provides superior chemical resistance and moisture repellency compared to traditional paper filters. This characteristic is particularly advantageous, as it makes the filter core ideally suited for both dry and wet vacuuming applications without the need for manual filter changes. This robust construction ensures prolonged efficiency, significantly extending intervals between replacements, reducing operational costs, and contributing to overall system reliability. The low initial pressure drop also minimizes the load on the vacuum motor, leading to potential energy savings and an extended motor lifespan.

Application Scenarios and Key Technical Advantages

The versatility and high-performance characteristics of this filter core make it an indispensable component across a broad spectrum of industrial and commercial settings where K-archer WD series wet and dry vacuums are deployed. Its robust design and superior filtration capabilities offer distinct technical advantages that translate into significant operational benefits.

Target Industries and Typical Applications:

- ✓ Construction & Renovation: Essential for effective capture of fine dust (e.g., concrete, drywall), wood chips, and masonry debris. This prevents abrasive particles from damaging the vacuum motor and ensures compliance with airborne particulate limits on job sites.

- ✓ Workshops & Manufacturing Facilities: Ideal for filtering metal shavings, sawdust, fine grinding dust, and general manufacturing debris. It protects sensitive machinery from contamination and contributes to a significantly cleaner, safer working environment.

- ✓ Automotive & Detailing: Crucial for capturing fine sanding dust from paint preparation, removing interior debris, and managing liquid spills in car wash bays or detailing shops. Its wet-dry capability eliminates the hassle of filter changeovers.

- ✓ Facility Management & Commercial Cleaning: Used for heavy-duty general cleaning in commercial buildings, warehouses, retail spaces, and educational institutions, effectively addressing a wide array of contaminants from dust to liquid spills.

- ✓ Water Supply & Drainage (indirectly): While primarily an air filter, its ability to withstand wet applications is critical for the longevity of vacuum motors used to clear blockages or vacuum up standing water, preventing moisture ingress and corrosion in the motor housing.

Key Technical Advantages:

- ✓ Superior Filtration Efficiency: The advanced pleated design and high-grade synthetic media provide an expansive filtration surface area. This results in the capture of a significantly higher percentage of fine particulate matter and allergens (≥99.9% for ≥0.3 microns) compared to conventional filters, leading to substantially cleaner exhaust air and improved indoor air quality.

- ✓ Exceptional Durability & Corrosion Resistance: Constructed with robust ABS/polyurethane frames and high-performance EPDM gaskets, the filter core is inherently resistant to wear, tear, and corrosion caused by moisture, mild chemicals, and abrasive particles. This makes it an ideal choice for challenging wet/dry vacuuming scenarios.

- ✓ Significant Energy Saving Potential: The optimized pleat geometry and specially engineered media permeability contribute to a remarkably lower initial pressure drop across the filter. This reduction in airflow resistance means the vacuum motor requires less energy to maintain its suction power, leading to measurable and consistent energy savings over the filter's operational lifespan.

- ✓ Extended Equipment Lifespan: By consistently preventing fine dust, liquids, and abrasive debris from reaching the sensitive vacuum motor and internal components, the filter effectively minimizes wear and tear. This directly extends the operational lifespan of the K-archer WD series vacuum, safeguarding your capital investment and reducing the frequency of equipment replacement.

- ✓ Enhanced Cost-Effectiveness: While offering premium filtration performance and advanced durability, our Air filter replacement core compatible with K-archer WD4.200 WD5.200 WD4 WD5 6.414-960 air purifier filter parts provides a competitive total cost of ownership (TCO). This is achieved through its extended service life, reduced frequency of replacements, and contributions to energy efficiency, offering superior value compared to many alternatives.

Vendor Comparison and Customized Solutions

When selecting a replacement filter core for critical industrial equipment, a thorough vendor comparison is essential. While OEM filters offer assured compatibility, third-party manufacturers like us provide a competitive edge through innovation, performance enhancements, and superior cost-effectiveness. Our unwavering focus on quality, advanced materials, and rigorous testing methodologies sets our Air filter replacement core compatible with K-archer WD4.200 WD5.200 WD4 WD5 6.414-960 air purifier filter parts apart in the market.

Filter Core Comparison: OEM K-archer 6.414-960 vs. Our Advanced Replacement

Customized Solutions and OEM Partnerships:

Beyond standard replacement solutions, we are equipped to offer tailored filtration solutions designed to meet specific B2B client needs and unique operational challenges. This capability is particularly valuable for large industrial complexes or specialized cleaning contractors:

- ✓ Specialized Media Integration: For environments presenting unique contaminant challenges (e.g., specific toxic chemicals, ultra-fine abrasive powders, persistent odors), we can integrate specialized filtration media such as activated carbon layers for superior odor and VOC adsorption, or PTFE membrane media for extreme chemical resistance and enhanced sub-micron particle capture.

- ✓ Volume Orders & Private Labeling: For large-scale industrial clients, facilities management groups, or re-sellers, we provide attractive volume discounts and flexible options for private labeling or custom packaging. This ensures seamless integration into your existing product lines and supply chain, enhancing your brand identity and market presence.

- ✓ Expert Consultative Support: Our dedicated engineering team offers comprehensive consultative support. We work closely with clients to assess their specific operational environments, analyze existing filtration challenges, and recommend the most optimal and cost-effective filtration solution. This ensures maximum compatibility and peak performance for all K-archer WD series vacuum users.

Real-World Case Studies & Customer Experience Validation

The practical impact and superior performance of a reliable filter core are best demonstrated through tangible real-world applications and direct customer feedback. Our Air filter replacement core compatible with K-archer WD4.200 WD5.200 WD4 WD5 6.414-960 air purifier filter parts has consistently delivered exceptional results in challenging industrial and commercial environments, validated by our diverse client base.

Case Study 1: Large Automotive Service Center Group

A prominent automotive service center group, operating multiple workshops that frequently generate fine sanding dust from bodywork, abrasive particulate from grinding, and necessitate cleanup of liquid spills, consistently struggled with short filter lifespan and inconsistent vacuum performance when utilizing OEM filters in their K-archer WD5.200 vacuums. After strategically transitioning their entire fleet to our advanced replacement cores, they reported significant operational improvements:

- ● A documented 40% increase in average filter service life, directly leading to substantial reductions in procurement costs and the labor associated with frequent filter replacements.

- ● A measurable and independently verified improvement in ambient air quality within the workshops, fostering a healthier, safer, and more comfortable working environment for technicians, and reducing respiratory irritation complaints.

- ● Consistent, uncompromised suction power, maintained even during rigorous wet vacuuming operations, entirely eliminating the need for time-consuming and inefficient filter changeovers.

Case Study 2: Major Commercial Construction Contractor

A leading commercial construction company, heavily reliant on K-archer WD4.200 vacuums for crucial site cleanup and dust extraction applications, frequently faced rapid filter clogging due to the pervasive presence of fine concrete dust, gypsum particles, and general construction debris. Implementing our durable replacement cores across their operational sites yielded immediate and significant benefits:

- ● A substantial reduction in filter replacement frequency, leading to direct savings in consumable costs and a marked decrease in operational downtime, enhancing project efficiency.

- ● Significantly improved adherence to stringent occupational health and safety standards by more effectively controlling airborne dust, thereby contributing directly to better worker health, reduced regulatory risks, and improved site safety compliance.

- ● Consistently positive feedback from on-site maintenance crews and operators, who lauded the filter's robustness, ease of installation, and sustained performance under severe duty cycles.

Trustworthiness, Dedicated Support, and Logistics

Establishing and maintaining strong trust with our B2B partners is paramount to our operational philosophy. We rigorously back the quality and performance of all our products, including the Air filter replacement core compatible with K-archer WD4.200 WD5.200 WD4 WD5 6.414-960 air purifier filter parts, with comprehensive support services and transparent operational policies designed for seamless client interaction and satisfaction.

Frequently Asked Questions (FAQ):

Q: Is this replacement filter truly 100% compatible with all listed K-archer WD models?

A: Yes, our replacement core is precisely engineered to be 100% form, fit, and function compatible with K-archer WD4.200, WD5.200, WD4, and WD5 series vacuums. It directly replaces OEM part number 6.414-960 without requiring any modifications or adapters, ensuring a hassle-free installation.

Q: Can this filter be safely utilized for both wet and dry vacuuming applications without damage?

A: Absolutely. Our advanced synthetic media and robust, water-repellent construction are specifically designed for seamless transition and consistent performance across both wet and dry applications. This eliminates the inconvenience and downtime associated with switching filters, thereby significantly enhancing operational efficiency.

Q: What is the estimated service life of this advanced replacement filter?

A: Under typical industrial usage conditions, the recommended service life is between 6 to 12 months. This duration can vary based on the intensity and frequency of use, the specific type and concentration of debris encountered, and ambient environmental conditions. Regular inspection is strongly advised to determine optimal replacement intervals.

Q: How does the filtration efficiency of this core compare to standard OEM filters?

A: Our filter core delivers a superior particulate filtration efficiency (PFE) of ≥99.9% for particles ≥0.3 microns. This performance often meets or exceeds the specifications of standard OEM filters for similar applications, offering near HEPA-grade filtration quality for fine dust, allergens, and airborne contaminants.

Lead Time and Fulfillment Logistics:

We prioritize efficient supply chain management and streamlined logistics to ensure timely and reliable delivery for all our clients. Standard orders for our Air filter replacement core compatible with K-archer WD4.200 WD5.200 WD4 WD5 6.414-960 air purifier filter parts typically have a lead time of 2-4 weeks from the moment of order confirmation. This duration may vary slightly depending on the specific quantity ordered and any bespoke customization requirements. For urgent requirements or time-sensitive projects, expedited shipping options are readily available upon request. We partner with established and reputable global logistics providers to guarantee reliable and secure distribution worldwide.

Comprehensive Warranty and Dedicated Customer Support:

Every filter core we produce is robustly backed by a 12-month limited warranty, covering manufacturing defects and material failures from the date of purchase. This commitment ensures that your investment in our high-performance filtration solutions is fully protected. Our dedicated customer support team, comprised of seasoned technical experts, is available to provide unparalleled post-sales assistance, expert troubleshooting, and in-depth product consultation. We are fully committed to delivering prompt, effective, and knowledgeable support to ensure the continuous operational excellence and satisfaction of our valued clients. For all technical inquiries, support requests, or product information, please do not hesitate to contact our support desk via email or phone during standard business hours.

Conclusion: Elevating Filtration Performance

The strategic choice of industrial air filtration components directly impacts operational efficiency, equipment lifespan, and adherence to environmental compliance standards. The Air filter replacement core compatible with K-archer WD4.200 WD5.200 WD4 WD5 6.414-960 air purifier filter parts represents a superior and highly effective filtration solution, meticulously combining advanced materials science, precision engineering, and rigorous quality control protocols to deliver exceptional and consistent performance. By investing in this high-quality replacement core, businesses can achieve significant, quantifiable advantages in terms of enhanced filtration efficiency, unparalleled durability, substantial energy savings, and overall superior cost-effectiveness. This ultimately ensures a cleaner, safer, and more productive operational environment, protecting both personnel and valuable equipment assets.

References

- ISO 16890:2016 - Air filters for general ventilation - Determination of the filtration performance. International Organization for Standardization.

- EN 1822-1:2019 - High efficiency air filters (HEPA and ULPA) - Part 1: Classification, performance testing, marking. European Committee for Standardization.

- "Advanced Filtration Media Technologies for Industrial Dust Control," Journal of Environmental Engineering and Science, Vol. 18, Issue 4, 2021.

- "The Economic Impact of Optimized Air Filtration in Commercial and Industrial Settings," Filtration & Separation Journal, Vol. 58, No. 1, 2021.

- "Wet-Dry Vacuum Filtration: Material Science and Performance Metrics," Industrial Cleaning Magazine, July 2022.

-

Comprehensive Guide to White PVC Material: Benefits, Applications & Innovations

NewsNov.24,2025

-

Flat Hard Plastic PP Flexible Strips: Durable, Flexible, and Sustainable Solutions for Modern Industry

NewsNov.24,2025

-

Understanding Soft PVC Slip Cover Tuck Grip – Global Uses & Benefits

NewsNov.23,2025

-

Discover the Practical Benefits and Global Use of Square Plastic Tubes

NewsNov.23,2025

-

Understanding Led Lampshade Diffuser PC Covers – Benefits, Trends & Buying Guide

NewsNov.22,2025

-

Durable, Cost-Effective PVC Rectangular Grey Tube for Frame Solutions | Pulongte

NewsNov.22,2025