Top Window Seal Strip Adhesive Companies | Strong, Durable Seals

Sep . 22, 2025 13:30 Back to list

Top Window Seal Strip Adhesive Companies | Strong, Durable Seals

Introduction to Advanced Sealing Solutions and Leading Manufacturers

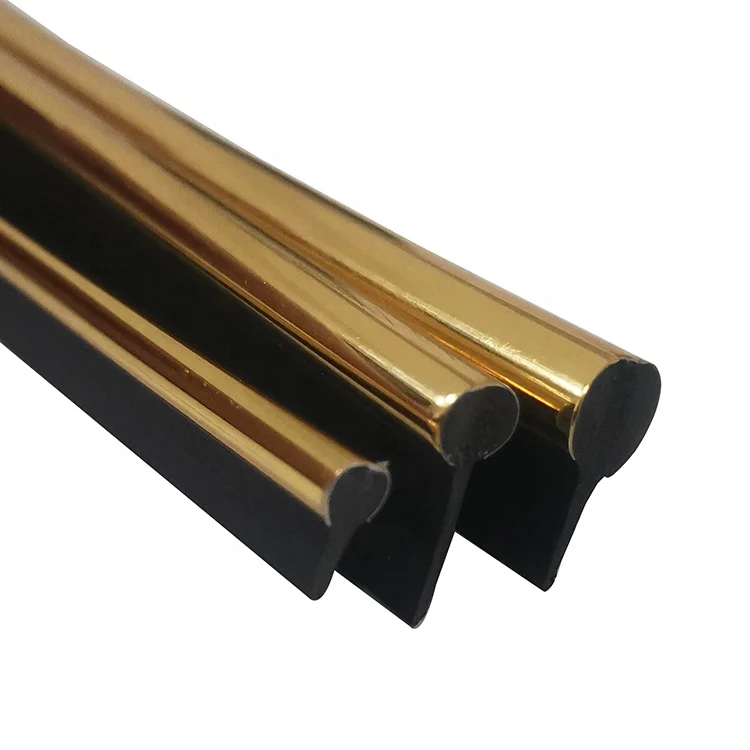

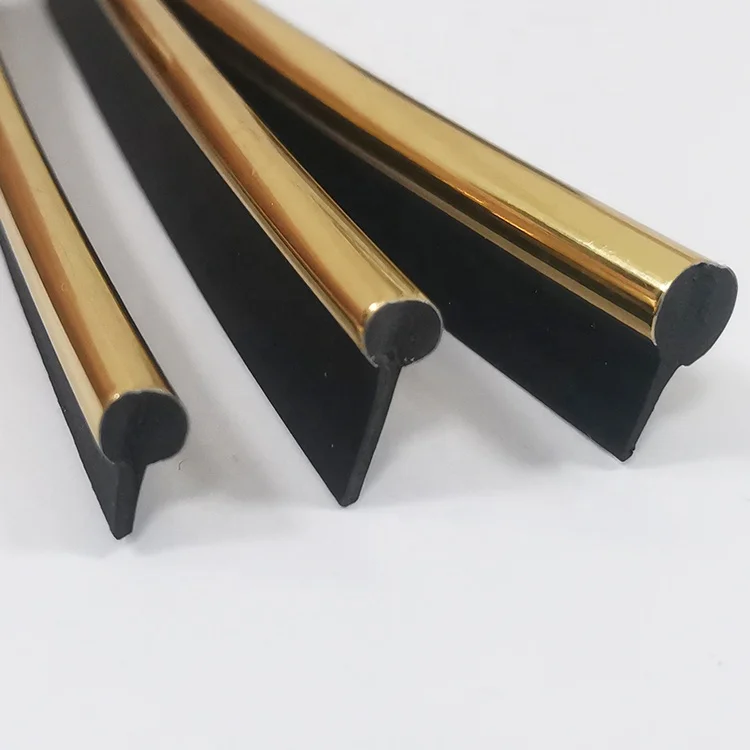

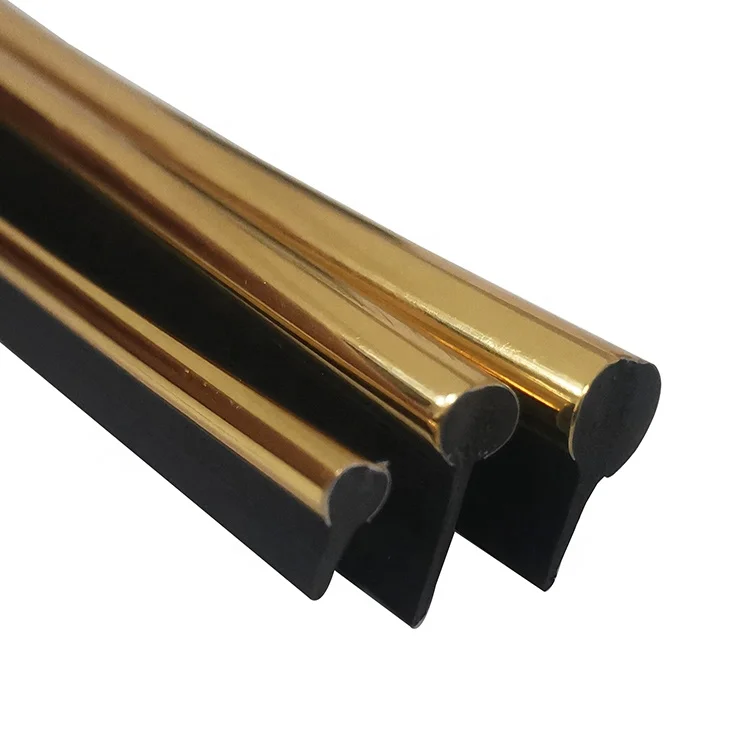

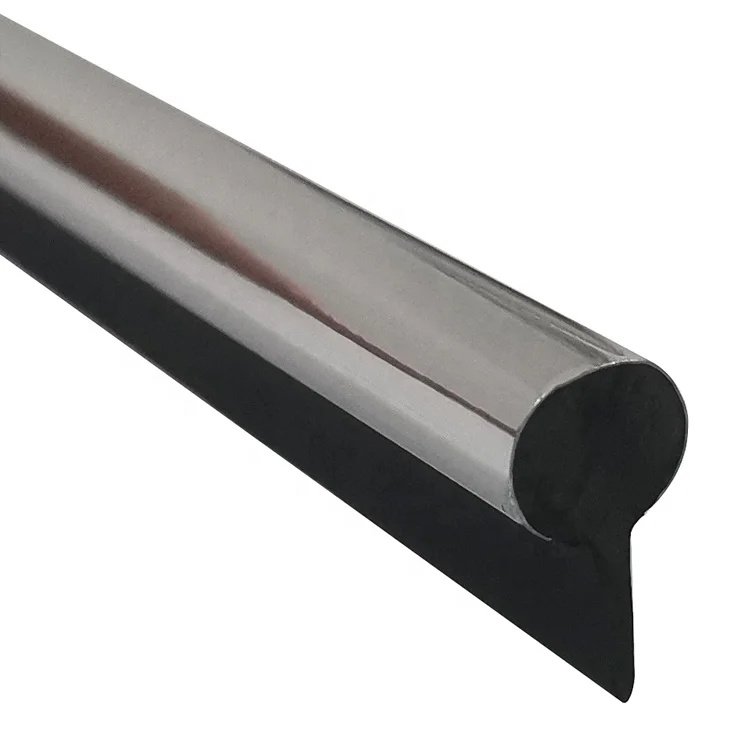

In industrial and architectural applications, the integrity of a structure often hinges on the quality of its sealing components. Window seal strips, in particular, play a pivotal role in energy efficiency, soundproofing, and protection against environmental elements. The market for these critical components is driven by specialized manufacturers and suppliers, encompassing a wide range of materials and adhesive technologies. Understanding the capabilities of leading window seal strip adhesive companies is essential for procurement professionals and engineers seeking optimal performance and reliability. These entities often possess diverse manufacturing expertise, extending from specific window sealing profiles to broader flexible PVC solutions, such as the customized edging strips for furniture, showcasing their mastery in extrusion and adhesive application.

The selection of the right seal strip adhesive is critical, influencing everything from application ease to long-term durability in varied climates. Reputable window seal strip adhesive manufacturer firms differentiate themselves through material science innovation, precision engineering, and adherence to stringent quality controls. Their portfolios typically include a variety of flexible profiles, offering solutions for complex sealing challenges across multiple sectors.

Current Industry Trends and Market Dynamics in Seal Strip Technology

The landscape for window seal strip technology is continuously evolving, driven by demands for greater sustainability, enhanced performance, and smart material integration. Key trends include the development of eco-friendly materials, such as bio-based or recycled polymers, and advancements in adhesive formulations that offer stronger bonds and longer service life under extreme conditions. There's also a significant shift towards custom-engineered solutions, where window seal strip adhesive companies are increasingly offering bespoke designs to meet highly specific client requirements, optimizing for factors like UV resistance, temperature extremes, and chemical inertness.

Furthermore, the integration of automation and artificial intelligence in manufacturing processes allows for greater precision and consistency in producing window seal strip adhesive products. This reduces waste and improves overall product quality, providing a competitive edge for leading window seal strip adhesive suppliers. The market also sees growth in multi-functional seal strips that incorporate additional features like acoustic dampening or enhanced thermal barriers, reflecting a comprehensive approach to environmental control within structures.

Comprehensive Manufacturing Process Flow for Adhesive Seal Strips

The production of high-performance adhesive seal strips is a sophisticated multi-stage process, demanding precision at every turn. It typically involves material compounding, extrusion or molding, surface preparation, adhesive application, and rigorous quality control. The primary materials used often include EPDM (Ethylene Propylene Diene Monomer), Silicone, PVC (Polyvinyl Chloride), and TPE (Thermoplastic Elastomer), each selected for specific properties like flexibility, temperature resistance, or chemical compatibility.

Process Flow Schematic:

Step 1: Material Compounding & Preparation

Selection of raw polymers (e.g., EPDM granules, silicone elastomers), blending with additives (UV stabilizers, colorants, vulcanizing agents, plasticizers) to achieve desired material properties. Precision mixing ensures homogeneity.

↓

Step 2: Profile Extrusion or Compression Molding

For continuous profiles, materials are fed into an extruder, melted, and forced through a die to create the desired cross-sectional shape. For complex or specific geometries, compression molding might be employed. This often includes co-extrusion for multi-durometer or multi-color profiles.

↓

Step 3: Curing/Vulcanization

For thermoset materials like EPDM or Silicone, the extruded or molded profiles undergo a curing process (e.g., in a hot air oven or salt bath) to cross-link the polymer chains, providing elasticity and permanent shape retention.

↓

Step 4: Surface Treatment & Adhesive Application

The surface where the adhesive will be applied is meticulously cleaned and often primed (e.g., corona treatment, plasma treatment) to enhance adhesion. A pressure-sensitive adhesive (PSA) or heat-activated adhesive layer is then precisely laminated or coated onto the profile, often with a release liner for protection.

↓

Step 5: Cutting, Packaging & Quality Control

The continuous strips are cut to specified lengths, then coiled or packed. Throughout the process, rigorous testing is conducted, including dimensional checks, Shore A hardness, tensile strength, compression set, and adhesive peel strength. Compliance with standards like ISO 9001 and ASTM D2000 is paramount.

Target industries for these advanced seals include automotive (door seals, trunk seals), construction (window and door frames, curtain walls), marine (watertight seals), and HVAC systems (duct seals). Advantages include enhanced energy saving through superior insulation, robust corrosion resistance, and extended service life due to high-quality materials and stringent manufacturing. This meticulous process ensures that products from leading window seal strip adhesive factory operations deliver consistent, high-performance results.

Technical Specifications and Material Science of High-Performance Seal Strips

High-performance window seal strips are engineered to provide durable, effective sealing under a myriad of conditions. The material science behind these components is complex, involving precise formulations to achieve desired mechanical, chemical, and thermal properties. Understanding key technical specifications is crucial for material selection and performance validation.

Typical Product Specifications for a High-Performance EPDM Window Seal Strip with PSA:

These parameters are critical in determining a seal's suitability for specific environments. For instance, a low compression set ensures the seal maintains its shape and sealing force over time, preventing leakage. High adhesion strength guarantees the seal remains affixed to the substrate even under stress. The expertise of leading window seal strip adhesive companies lies in their ability to formulate and manufacture materials that consistently meet or exceed these demanding specifications.

Diverse Application Scenarios and Target Industries

The versatility of adhesive window seal strips extends across numerous high-demand industries, where their properties contribute significantly to operational efficiency, safety, and longevity. Key sectors include:

- Construction and Architecture: Used extensively in residential, commercial, and industrial buildings for sealing windows, doors, curtain walls, and facade elements. They provide superior thermal insulation, reducing HVAC load and energy consumption, while also offering excellent acoustic insulation against external noise.

- Automotive Industry: Critical for sealing windows, windshields, doors, and trunks. These seals enhance vehicle aerodynamics, reduce cabin noise, prevent water ingress, and contribute to passenger comfort and safety. Their durability against temperature fluctuations and vibrations is paramount.

- HVAC Systems: Employed to seal ducts, vents, and air handling units, ensuring airtight systems that prevent energy loss and maintain air quality. In this context, resistance to moisture and fluctuating temperatures is vital.

- Industrial Enclosures and Machinery: Used for sealing electrical cabinets, control panels, and machinery access points, protecting sensitive internal components from dust, moisture, and chemical exposure. This is crucial for maintaining equipment reliability and extending service life.

- Marine and Aerospace: Where extreme environmental conditions are common, specialized seal strips offer watertight and airtight barriers, resisting saltwater, UV radiation, and rapid temperature changes, ensuring structural integrity and safety.

In typical application scenarios, such as the sealing of a commercial building's glass facade, advanced EPDM window seal strips with a high-performance acrylic adhesive ensure a long-lasting, weather-tight bond. This significantly contributes to the building's energy rating by minimizing heat transfer and air leakage. Similarly, in a petrochemical facility, specialized chemical-resistant seals on instrument enclosures prevent ingress of corrosive vapors, demonstrating their critical role in safety and operational continuity. The comprehensive expertise offered by proficient window seal strip adhesive exporter companies caters to these diverse and demanding requirements.

Technical Advantages of Partnering with Leading Window Seal Strip Adhesive Exporters

Engaging with established window seal strip adhesive exporters offers a multitude of technical advantages crucial for securing superior sealing solutions. These companies leverage extensive R&D, advanced manufacturing technologies, and deep material science knowledge to produce seals that outperform conventional alternatives.

- Enhanced Durability and Longevity: Utilizing high-grade polymers like EPDM or silicone, these seals exhibit exceptional resistance to UV radiation, ozone, extreme temperatures, and general weathering, leading to significantly extended service life compared to standard rubber or foam seals. This minimizes replacement costs and maintenance.

- Superior Sealing Performance: Precision extrusion and co-extrusion technologies enable the creation of complex profiles with tight tolerances, ensuring optimal compression and a complete, impermeable barrier against air, dust, and water ingress. Advanced adhesive formulations maintain a strong bond even under dynamic stress.

- Optimized Energy Efficiency: High-quality seal strips provide excellent thermal insulation, crucial for minimizing heat loss or gain in buildings and vehicles. This translates directly into reduced energy consumption for heating and cooling systems, contributing to lower operational costs and environmental impact.

- Noise Reduction Capabilities: The inherent material properties and intricate designs of these seals offer superior acoustic dampening, significantly reducing noise transmission from outside environments into interiors, thereby enhancing comfort and operational focus.

- Corrosion and Chemical Resistance: Formulations can be tailored to withstand exposure to specific chemicals, oils, and industrial pollutants, making them ideal for challenging industrial environments where standard seals would quickly degrade.

- Customization and Design Flexibility: Leading manufacturers can produce bespoke profiles, colors, and material combinations, offering unparalleled flexibility to integrate seamlessly with specific architectural designs or industrial machinery requirements.

These advantages are not merely product features; they translate into tangible benefits for end-users, including reduced operational expenditures, enhanced system reliability, improved user comfort, and compliance with stringent industry standards. Working with experienced window seal strip adhesive companies ensures access to solutions that are both technically advanced and economically viable.

Vendor Comparison: Differentiating Among Window Seal Strip Adhesive Suppliers

Choosing the right window seal strip adhesive supplier is paramount for ensuring product quality, delivery reliability, and long-term cost-effectiveness. A comprehensive vendor comparison should evaluate several key differentiators beyond just price.

Comparison Table: Key Material Properties for Window Seal Strips

When evaluating window seal strip adhesive companies, consider their R&D capabilities, especially for novel materials or specialized adhesive technologies. Look for providers who offer comprehensive technical support, from initial design consultation to post-installation troubleshooting. Certifications (e.g., ISO 9001, IATF 16949 for automotive), adherence to international standards (e.g., ASTM, DIN), and a track record of successful projects are strong indicators of reliability and quality. Furthermore, an ideal partner will demonstrate flexibility in offering customized solutions and have efficient logistics for global distribution, ensuring timely delivery and responsive service. Online platforms providing window seal strip adhesive quotes can offer initial insights, but deeper technical discussions are indispensable.

Customized Solutions and Design Flexibility in Seal Strip Production

Modern industrial and architectural projects frequently demand sealing solutions that go beyond off-the-shelf products. This is where the capability of window seal strip adhesive companies to provide customized solutions becomes invaluable. Design flexibility encompasses various aspects, from unique profile geometries to specialized material compositions and adhesive types.

Leading manufacturers offer bespoke engineering services, starting with a detailed analysis of application requirements, environmental conditions, and performance criteria. This collaborative approach allows for the development of seal profiles optimized for specific gaps, compression loads, and aesthetic integration. Customization options include:

- Custom Profiles and Dimensions: Designing unique cross-sections to perfectly fit unusual window frames, architectural joints, or industrial enclosures. This can involve complex co-extruded profiles combining materials of different hardness or colors.

- Material Blends and Formulations: Developing custom polymer blends to achieve specific properties such as enhanced flame retardancy, chemical resistance, UV stability, or a wider operational temperature range.

- Adhesive Selection: Tailoring adhesive types (e.g., acrylic, rubber-based, silicone) and thicknesses to ensure optimal bond strength and longevity on diverse substrates (metal, glass, plastic, painted surfaces), considering temperature and moisture exposure.

- Color Matching: Producing seals in specific colors to seamlessly integrate with aesthetic requirements, particularly important in architectural and furniture applications where visual consistency is key.

- Special Features: Integrating features like internal wire reinforcement for structural integrity, anti-microbial additives for hygiene-sensitive environments, or textured surfaces for improved grip or appearance.

This level of customization ensures that the sealing solution is not just a component, but an integral part of the overall design, maximizing performance and efficiency. Companies that excel in this area are often at the forefront of innovation, continuously pushing the boundaries of material science and manufacturing technology.

Real-World Application Case Studies and Success Stories

The practical impact of high-quality window seal strips is best illustrated through real-world application case studies. These examples demonstrate how specialized window seal strip adhesive companies provide tangible solutions to complex engineering challenges.

Case Study 1: High-Rise Commercial Building Facade

Challenge: A new high-rise commercial building in a rapidly developing urban area faced significant challenges with noise pollution and maintaining consistent indoor climate due to external temperature fluctuations. The original window seals were failing to provide adequate thermal and acoustic insulation.

Solution: A leading window seal strip adhesive manufacturer was consulted. They developed a custom co-extruded EPDM seal strip with a specialized cellular structure and high-tack acrylic adhesive. The unique profile was designed to fit precisely into the aluminum window frame channels, ensuring maximum compression and minimal air infiltration. The EPDM material provided excellent UV and ozone resistance, ensuring long-term durability in sun-exposed conditions.

Outcome: Post-installation, the building reported a 15% reduction in HVAC energy consumption and a significant decrease in indoor noise levels, enhancing occupant comfort and productivity. The client provided positive feedback, citing the seals' robust performance and the manufacturer's technical support as pivotal to project success.

Case Study 2: Automotive OEM Door Seal Enhancement

Challenge: An automotive OEM was looking to improve the sealing performance and reduce road noise in their premium vehicle line. Existing door seals exhibited minor air leaks at higher speeds and showed premature wear in cold climates.

Solution: A specialist among window seal strip adhesive companies collaborated with the OEM's engineering team. They designed a multi-chambered TPE seal strip with a co-extruded bulb and flange, integrated with a heat-activated adhesive for secure attachment to the vehicle body. The TPE formulation was optimized for low-temperature flexibility and high compression recovery, addressing the wear issue and ensuring consistent sealing across diverse climates.

Outcome: The new seal strips led to a measurable improvement in vehicle acoustics, with an average 2dB reduction in cabin noise at highway speeds. Durability tests confirmed extended service life, meeting the OEM's stringent quality standards. This solution enhanced the perceived quality and comfort of the vehicle, reinforcing brand reputation.

Ensuring Quality and Authoritativeness: Certifications and Partnerships

For B2B decision-makers, evaluating the authoritativeness and trustworthiness of window seal strip adhesive companies is paramount. This is primarily established through adherence to international standards, industry certifications, and strategic partnerships.

- ISO 9001: Certification in Quality Management Systems demonstrates a commitment to consistent quality, continuous improvement, and customer satisfaction throughout the manufacturing process.

- IATF 16949: For suppliers to the automotive industry, this technical specification defines the quality management system requirements, ensuring products meet the stringent demands of automotive OEMs.

- ASTM & DIN Standards: Compliance with American Society for Testing and Materials (ASTM) and Deutsches Institut für Normung (DIN) standards for material properties (e.g., hardness, tensile strength, compression set, aging) provides verifiable proof of product performance and reliability.

- REACH & RoHS Compliance: Adherence to environmental regulations like REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances) ensures products are safe for both users and the environment.

- Years of Service and Client Portfolios: A long operational history coupled with a diverse portfolio of reputable clients in demanding sectors (e.g., automotive, aerospace, construction) serves as a strong indicator of experience and proven capability.

Reputable window seal strip adhesive companies invest heavily in R&D and quality assurance, often maintaining in-house testing laboratories to validate product performance against specified standards. Their authoritative position is built not just on products, but on a foundation of scientific rigor, transparent processes, and unwavering commitment to excellence.

Trustworthiness: FAQs, Lead Time, Warranty, and Support

Building trust with B2B clients requires transparency and robust support mechanisms. Leading window seal strip adhesive companies understand this and provide clear information regarding their processes, product guarantees, and customer assistance.

Frequently Asked Questions (FAQs):

Q1: How do I select the right adhesive for my application?

A1: Selection depends on the substrate material, environmental exposure (temperature, moisture, chemicals), required bond strength, and desired application method. Consult with our technical team for personalized recommendations based on your specific project parameters.

Q2: What is the typical lifespan of your window seal strips?

A2: Our high-performance EPDM and Silicone seals are designed for a service life of 10-20 years or more under normal operating conditions, owing to their excellent UV, ozone, and temperature resistance. PVC seals typically offer 5-10 years, depending on exposure.

Q3: Can your seal strips be used in extreme temperatures?

A3: Yes, we offer materials specifically formulated for extreme conditions. Silicone seals can withstand temperatures from -60°C to +230°C, while EPDM is effective from -40°C to +120°C. Consult product specifications for exact material limits.

Q4: Do you provide custom design and prototyping services?

A4: Absolutely. We specialize in custom solutions, from profile design and material formulation to adhesive selection and prototyping. Our engineering team works closely with clients to develop seals that precisely meet unique requirements.

Lead Time and Fulfillment:

Standard products typically have a lead time of 2-4 weeks from order confirmation, depending on volume and current production schedules. Custom orders, requiring tooling and sample approvals, may range from 6-10 weeks. We maintain robust supply chain management and inventory systems to ensure efficient fulfillment and on-time delivery. Expedited shipping options are available upon request.

Warranty Commitments:

All our window seal strip adhesive products are backed by a comprehensive warranty against manufacturing defects and material failures under normal use conditions. Specific warranty durations vary by product type, typically ranging from 5 to 10 years. Details are provided with each product quotation and sales agreement, underscoring our confidence in product quality and longevity.

Customer Support and After-Sales Service:

Our commitment extends beyond product delivery. We offer dedicated technical support, providing expert assistance for installation guidance, troubleshooting, and performance optimization. Our customer service team is available via phone, email, and online portal during business hours, with emergency support options for critical projects. We aim to build lasting partnerships through responsive and reliable service.

Conclusion: The Future of Sealing Technology

The role of window seal strip adhesive technology is becoming increasingly vital in an era demanding greater efficiency, durability, and sustainability. As industries continue to evolve, so too will the solutions provided by innovative window seal strip adhesive companies. From advanced material science to bespoke engineering, these firms are at the forefront of developing sealing solutions that address complex environmental, structural, and operational challenges. Investing in high-quality, technically superior seal strips is not merely a purchase; it is a strategic decision that underpins long-term performance, economic viability, and environmental responsibility across a multitude of applications. The future promises even more integrated, intelligent, and sustainable sealing solutions, further solidifying the critical role of these specialized manufacturers.

References

- ASTM International. "Standard Specification for Flexible Cellular Materials—Sponge or Expanded Rubber." ASTM D1056.

- ISO 9001:2015. "Quality management systems — Requirements." International Organization for Standardization.

- Rubber Handbook: Compounding and Testing for Performance. Rapra Technology Ltd., 2001.

- Schrader, G. "Adhesion and Adhesives: Principles and Practice." Carl Hanser Verlag GmbH & Co. KG, 2013.

- Automotive Industry Action Group (AIAG). "IATF 16949:2016 - Quality management system requirements for automotive production and relevant service parts organizations."

-

Comprehensive Guide to White PVC Material: Benefits, Applications & Innovations

NewsNov.24,2025

-

Flat Hard Plastic PP Flexible Strips: Durable, Flexible, and Sustainable Solutions for Modern Industry

NewsNov.24,2025

-

Understanding Soft PVC Slip Cover Tuck Grip – Global Uses & Benefits

NewsNov.23,2025

-

Discover the Practical Benefits and Global Use of Square Plastic Tubes

NewsNov.23,2025

-

Understanding Led Lampshade Diffuser PC Covers – Benefits, Trends & Buying Guide

NewsNov.22,2025

-

Durable, Cost-Effective PVC Rectangular Grey Tube for Frame Solutions | Pulongte

NewsNov.22,2025