Oil Filters For Bomb ardier Can-Am Outlander 2003-2017 OEM

Oct . 17, 2025 09:00 Back to list

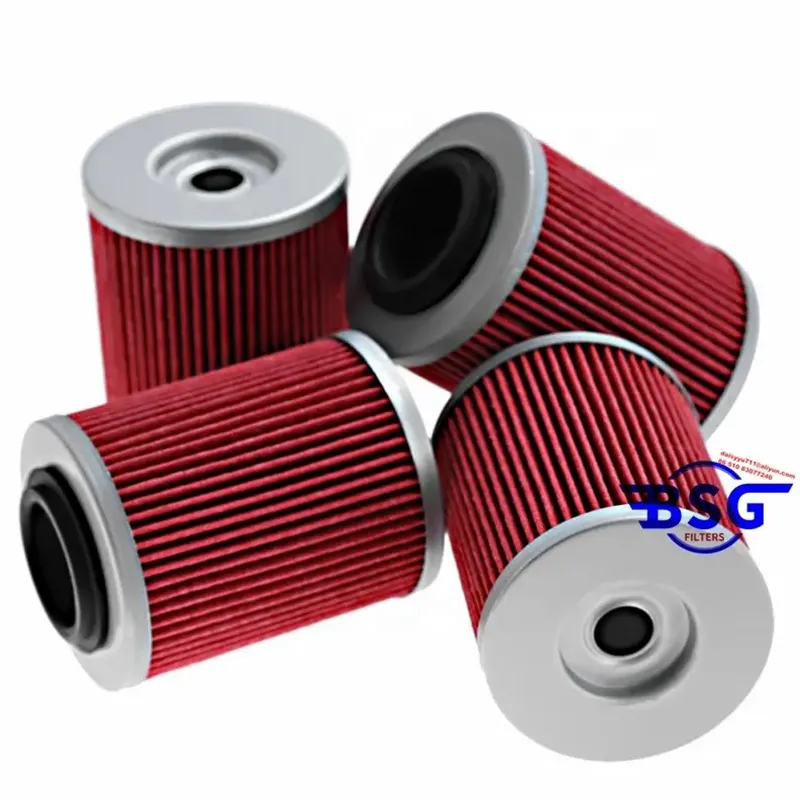

Oil Filters For Bomb ardier Can-Am Outlander 2003-2017 OEM

Real-world Guide to Oil Filters For Bomb ardier Can-Am Outlander 2003-2017 420256188 K N152 H F152

If you ride hard, wrench often, and care about the long life of your Rotax-powered ATV/UTV, the oil filter isn’t just a consumable—it’s cheap insurance. I’ve seen more than a few engines saved (and, frankly, a couple not-so-lucky ones) by choosing the right filter and changing it on time.

What’s trending in powersports filtration

Across the ATV/UTV market, riders are moving toward higher-efficiency media, silicone anti-drainback valves for cold starts, and filters validated under ISO 4548 protocols. Also seeing a rise: private-label options from established factories in Hebei, China, including the origin point for this unit—Xiangjiang Street South, Jinggangshan Road West, Qinghe County, Xingtai City, Hebei Province—where powersports filtration has quietly built a strong reputation.

Core specs (quick look)

| Part reference | BRP/Can‑Am 420256188; cross to HF152 / KN‑152 |

| Thread / gasket | M20 × 1.5; gasket OD ≈ 62 mm (real-world may vary by vendor) |

| Height / can dia. | ≈ 65 mm / ≈ 68 mm |

| Media | High-density cellulose or blended synthetic/cellulose, pleated |

| Bypass valve | Opens ≈ 8–12 psi to protect flow in cold/thick oil starts |

| Anti-drainback valve | Silicone or nitrile (silicone preferred for cold-climate starts) |

| Filtration performance | Typical for this class: ≥99% @ ≥20 μm per ISO 4548‑12, Beta ratios vary |

| Service interval | Around 50–100 hours (or per OEM manual and riding conditions) |

Applications and fit

Designed to replace BRP/Can‑Am 420256188 on Outlander models roughly 2003–2017 (400/500/650/800/1000), plus several Rotax-based platforms. Interestingly, this cross is also known from Aprilia twins—HF152/KN‑152 fit the ETV‑1000 Caponord, among others. To be honest, riders sometimes overlook this cross-compatibility; always verify by VIN and manual before ordering.

- ATV/UTV: trail, mud, towing, farm/forestry work

- Adventure touring (Aprilia Caponord) in a pinch—same filter family

How it’s made (quick process flow)

Materials are selected (media basis weight checked), then pleated and cured. Endcaps are bonded, center tube rolled, and the ADBV/bypass assembly installed. Cans are deep-drawn, seam-crimped, and each unit is leak-tested. Periodic lots undergo burst testing (target >200 psi), multi-pass efficiency testing per ISO 4548‑12, and collapse resistance checks. Facilities commonly certify to ISO 9001 and IATF 16949; compliance with RoHS/REACH is increasingly standard.

Vendor snapshot: OEM vs aftermarket

| Vendor | Notes | Pros | Watch-outs |

|---|---|---|---|

| BRP OEM 420256188 | Factory spec for Can‑Am | Known fit; warranty-friendly | Pricey in some regions |

| Hiflofiltro HF152 | TUV-certified production | Consistent QA; good value | Verify media variant |

| K&N KN‑152 | Performance-oriented | Strong build; wide availability | Cost a bit higher |

| Private-label (Hebei) | Customizable packaging/media | Great for fleets; bulk pricing | Demand ISO 4548 test data |

Customization for dealers and fleets

- Private label and color can options

- Media tuning (cellulose vs blend) based on dust load

- Batch certification: ISO 4548‑12 multi‑pass, burst, and flow curves

Case notes from the field

A utility Outlander 650 in a tree-service fleet switched to Oil Filters For Bomb ardier Can-Am Outlander 2003-2017 420256188 K N152 H F152-equivalent units with silicone ADBV. Cold-start knock virtually disappeared and used-oil analysis showed lower silicon and iron at 75 hours. Another rider—Aprilia Caponord—ran a Oil Filters For Bomb ardier Can-Am Outlander 2003-2017 420256188 K N152 H F152 cross and reported steadier idle pressure. Anecdotal? Sure, but it lines up with what many customers say.

Practical tips

- Confirm part number 420256188 for your VIN/year; Can‑Am spans multiple engines.

- Change around 50–100 hours or sooner in mud/sand; follow the OEM manual.

- After install, verify leaks and pressure; don’t over-torque an M20 × 1.5 stud.

Note: The description also references “HF152 Hiflo filtro Oil Filter Aprilia ETV‑1000 Caponord,” reflecting the commonly known cross. Always verify application specifics.

Authoritative references

-

Comprehensive Guide to White PVC Material: Benefits, Applications & Innovations

NewsNov.24,2025

-

Flat Hard Plastic PP Flexible Strips: Durable, Flexible, and Sustainable Solutions for Modern Industry

NewsNov.24,2025

-

Understanding Soft PVC Slip Cover Tuck Grip – Global Uses & Benefits

NewsNov.23,2025

-

Discover the Practical Benefits and Global Use of Square Plastic Tubes

NewsNov.23,2025

-

Understanding Led Lampshade Diffuser PC Covers – Benefits, Trends & Buying Guide

NewsNov.22,2025

-

Durable, Cost-Effective PVC Rectangular Grey Tube for Frame Solutions | Pulongte

NewsNov.22,2025