Acrylic Heat Bender Tool-Type A-Hebei Pulongte | Precision Bending, High-Temperature Heating

Sep . 19, 2025 22:25 Back to list

Acrylic Heat Bender Tool-Type A-Hebei Pulongte | Precision Bending, High-Temperature Heating

Acrylic heat bender tools have become essential in modern manufacturing and DIY projects, enabling precise shaping of acrylic sheets for a wide range of applications. Among the many tools available, the Acrylic Heat Bender Tool-Type A stands out for its innovative design, durability, and user-friendly features. This article provides an in-depth analysis of the product, its technical specifications, and the company behind it, Hebei Pulongte Rubber and Plastic Technology Co., Ltd., a leading manufacturer in the industry.

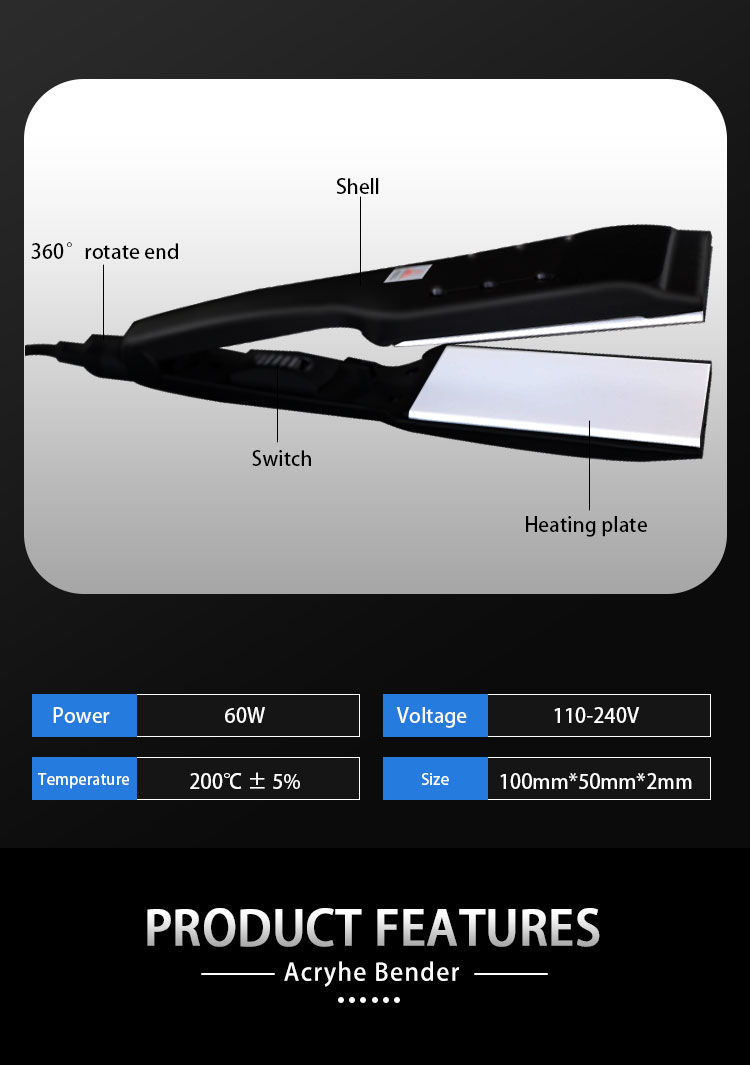

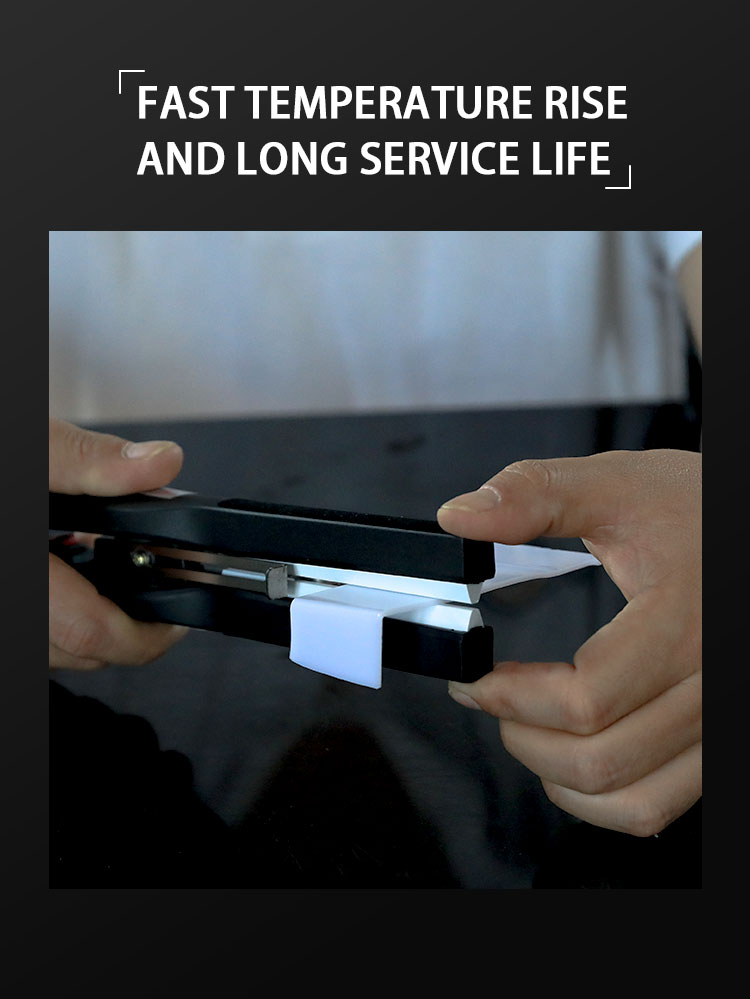

Figure 1: Acrylic heat bender tool in action, shaping materials for creative applications.

Product Overview and Key Features

The Acrylic Heat Bender Tool-Type A is a specialized device designed to heat and bend acrylic sheets with precision. Its primary function is to allow users to create custom shapes for products such as light covers, lampshades, and decorative trim caps. The tool is engineered to ensure consistent results, even for complex curves and angles.

- High-Temperature Heating Element: The tool features a robust heating system capable of reaching temperatures up to 300°C, ensuring efficient softening of acrylic materials without compromising their structural integrity.

- Adjustable Bending Jig: A customizable jig allows users to set the desired angle and curvature, making it suitable for both simple and intricate designs.

- Heat-Resistant Handles: The ergonomic handles are designed to withstand high temperatures, providing a safe and comfortable grip during operation.

- Compact and Portable Design: Despite its advanced features, the tool is lightweight and easy to transport, ideal for on-site applications or small workshops.

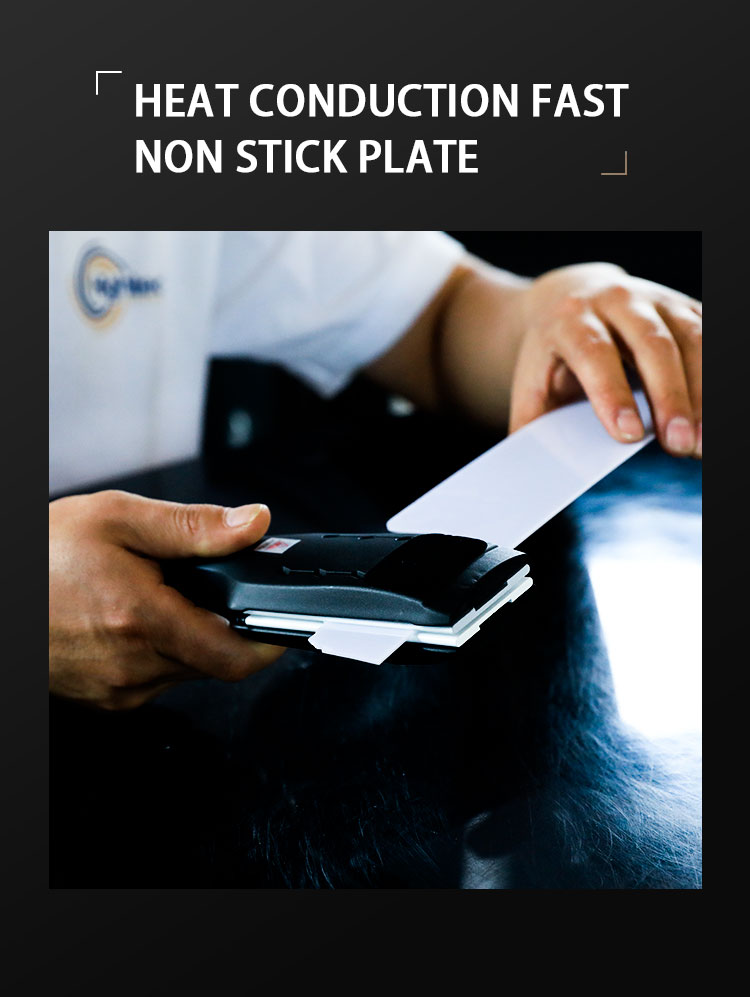

Figure 2: The tool's versatility in shaping acrylic for 3D metal trim caps and other decorative elements.

Technical Specifications

To fully understand the capabilities of the Acrylic Heat Bender Tool-Type A, it is essential to examine its technical specifications. Below is a detailed table outlining the product's key parameters:

| Parameter | Specification |

|---|---|

| Maximum Operating Temperature | 300°C |

| Heating Element Type | Resistance Heating Coil |

| Power Consumption | 1200W |

| Dimensions (L x W x H) | 450mm x 200mm x 150mm |

| Weight | 3.2kg |

| Material of Construction | Stainless Steel and Heat-Resistant Plastic |

| Compatibility | Acrylic Sheets (1-5mm Thickness) |

Applications and Use Cases

The Acrylic Heat Bender Tool-Type A is a versatile tool with applications across multiple industries. Its ability to create precise bends makes it a favorite among professionals and hobbyists alike. Key use cases include:

- Lighting Industry: Shaping acrylic sheets into lampshades, diffusers, and light covers for both residential and commercial lighting solutions.

- Interior Design: Crafting custom acrylic panels, partitions, and decorative elements for modern interiors.

- Signage and Displays: Producing curved or angled acrylic signs for retail stores, exhibitions, and advertising campaigns.

- Automotive and Aerospace: Manufacturing lightweight, durable acrylic components for vehicle interiors and aircraft cabins.

Figure 3: The Acrylic Heat Bender Tool-Type A in its standard configuration, highlighting its compact design.

Company Background: Hebei Pulongte Rubber and Plastic Technology Co., Ltd.

Founded in [Year], Hebei Pulongte Rubber and Plastic Technology Co., Ltd. has established itself as a leading manufacturer of acrylic and plastic processing tools. The company specializes in producing high-quality, innovative products that cater to both industrial and consumer markets. With a strong focus on research and development, Hebei Pulongte ensures that its tools meet the highest standards of performance and safety.

The company’s commitment to quality is reflected in its state-of-the-art manufacturing facilities and rigorous testing procedures. By leveraging advanced technologies and adhering to international standards, Hebei Pulongte has built a reputation for delivering reliable and durable products. Their extensive product line includes not only the Acrylic Heat Bender Tool-Type A but also a range of other tools for plastic and acrylic processing.

Figure 4: Hebei Pulongte's manufacturing facility, showcasing their dedication to quality and innovation.

Why Choose the Acrylic Heat Bender Tool-Type A?

While there are numerous acrylic bending tools available on the market, the Acrylic Heat Bender Tool-Type A offers several advantages that make it a top choice for professionals and enthusiasts:

- Superior Precision: The adjustable jig and controlled heating system ensure accurate bends, reducing the risk of material waste.

- Easy to Use: The tool is designed with user-friendliness in mind, featuring intuitive controls and a straightforward setup process.

- Durability: Constructed from high-quality materials, the tool is built to withstand frequent use and harsh environments.

- Cost-Effective: By enabling in-house production of custom acrylic parts, the tool helps users save time and money compared to outsourcing.

Figure 5: The tool's role in the supply chain, highlighting its importance for suppliers and manufacturers.

Industry Standards and Safety Compliance

The Acrylic Heat Bender Tool-Type A adheres to industry standards for safety and performance. Hebei Pulongte ensures that all products undergo thorough testing to meet requirements set by regulatory bodies. This includes compliance with electrical safety standards and material durability tests. For more information on NIST guidelines related to manufacturing standards, refer to the National Institute of Standards and Technology (NIST), which plays a critical role in developing measurement standards that support innovation and quality assurance across industries.

According to NIST, "Accurate measurements and reliable standards are foundational to advancing technology and ensuring the safety and efficacy of manufactured goods" (NIST, 2023). The Acrylic Heat Bender Tool-Type A exemplifies this principle by providing consistent, measurable results that meet the demands of modern manufacturing.

Figure 6: The production line at Hebei Pulongte's factory, emphasizing quality control and efficiency.

Conclusion

The Acrylic Heat Bender Tool-Type A is a testament to innovation in the field of acrylic processing. With its advanced features, user-friendly design, and adherence to industry standards, it is an invaluable tool for professionals and DIY enthusiasts. Manufactured by Hebei Pulongte Rubber and Plastic Technology Co., Ltd., a company committed to quality and excellence, the tool is a reliable choice for a wide range of applications.

Whether you are creating custom lighting solutions, interior design elements, or industrial components, the Acrylic Heat Bender Tool-Type A offers the precision and versatility needed to achieve outstanding results. For more information about the product or to explore other offerings from Hebei Pulongte, visit their official website here.

Figure 7: The tool's export potential, highlighting its global reach and demand.

References

National Institute of Standards and Technology (NIST). (2023). Standards and Innovation. Retrieved from https://www.nist.gov

-

Comprehensive Guide to White PVC Material: Benefits, Applications & Innovations

NewsNov.24,2025

-

Flat Hard Plastic PP Flexible Strips: Durable, Flexible, and Sustainable Solutions for Modern Industry

NewsNov.24,2025

-

Understanding Soft PVC Slip Cover Tuck Grip – Global Uses & Benefits

NewsNov.23,2025

-

Discover the Practical Benefits and Global Use of Square Plastic Tubes

NewsNov.23,2025

-

Understanding Led Lampshade Diffuser PC Covers – Benefits, Trends & Buying Guide

NewsNov.22,2025

-

Durable, Cost-Effective PVC Rectangular Grey Tube for Frame Solutions | Pulongte

NewsNov.22,2025