Window Seal Strip Adhesive Companies: Strong & Durable Seals

Aug . 13, 2025 01:20 Back to list

Window Seal Strip Adhesive Companies: Strong & Durable Seals

Understanding the Critical Role of Window Seal Strip Adhesive

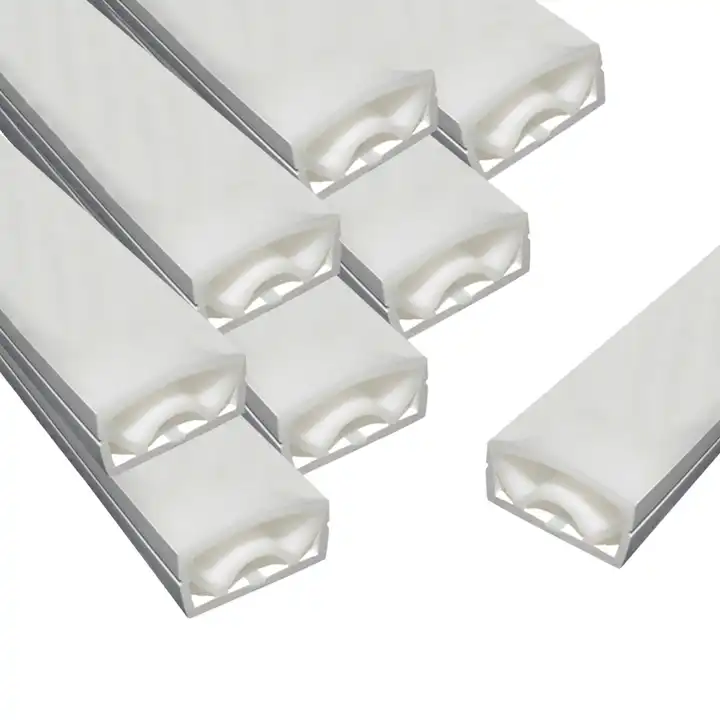

In modern construction and automotive industries, the integrity and performance of window systems heavily rely on advanced sealing solutions. High-quality adhesives for window seal strips are indispensable, providing crucial barriers against environmental factors such as moisture, air, and noise. Selecting the right adhesive from reputable window seal strip adhesive companies is a strategic decision that directly impacts the durability, energy efficiency, and overall comfort of structures and vehicles. These specialized adhesives offer excellent adhesion to diverse substrates, including glass, metal, PVC, and wood, ensuring a long-lasting, flexible, and robust seal that withstands dynamic stresses and extreme weather conditions.

The industry landscape for window seal strip adhesive is continuously evolving, driven by advancements in material science and increasing demands for sustainability and performance. Leading manufacturers are focusing on developing eco-friendly formulations with low Volatile Organic Compound (VOC) content, enhancing thermal insulation properties, and extending service life. This commitment to innovation ensures that window seal strip products not only meet but exceed stringent international building codes and automotive standards, contributing significantly to improved structural integrity and reduced energy consumption. The emphasis on high-performance adhesives reflects a broader industry trend towards integrated, maintenance-free solutions that deliver superior protection and longevity across various applications.

The Manufacturing Process of Advanced Window Seal Strip Adhesives

The production of high-performance window seal strip adhesive involves a sophisticated multi-stage manufacturing process, ensuring consistent quality and optimal performance characteristics. It typically begins with the meticulous selection of raw materials, including synthetic polymers (such as silicones, EPDM, acrylics, or butyl rubber), tackifiers, plasticizers, fillers, and curing agents. Each component is chosen for its specific contribution to the adhesive's properties, such as flexibility, adhesion strength, UV resistance, and temperature stability. Quality assurance starts at this foundational stage, with suppliers providing material certifications to ensure compliance with industry standards like ISO 9001 for quality management.

The core manufacturing process involves precision blending and compounding. Polymers are mixed with other additives in controlled environments, often under specific temperature and pressure conditions, to achieve a homogeneous mixture. For certain types of adhesives, extrusion processes are employed to form the adhesive into specific shapes, like tapes or beads, which are then cured using heat, UV light, or moisture, depending on the adhesive chemistry. Post-curing, the products undergo rigorous testing, including peel adhesion tests (ASTM D903), shear strength tests (ASTM D1002), and accelerated weathering tests (ASTM G154/G155) to simulate long-term performance under various environmental stresses. Only products meeting stringent internal and external specifications, such as AAMA standards for window performance, are approved for distribution by leading window seal strip adhesive manufacturer and window seal strip adhesive exporter companies.

Key Technical Parameters and Application Scenarios

The performance of window seal strip adhesive products is defined by several critical technical parameters, including tensile strength, elongation at break, durometer hardness (e.g., Shore A), operating temperature range, UV resistance, and chemical compatibility. For instance, a high-quality silicone-based adhesive may exhibit an elongation of over 500% and a temperature range from -50°C to +150°C, offering exceptional flexibility and thermal stability. Its excellent UV resistance ensures non-yellowing and degradation-free performance in direct sunlight, critical for outdoor applications. Butyl adhesives, known for their strong tack and moisture barrier properties, are often preferred for sealing double-glazing units and ensuring air-tightness in specific automotive assemblies.

These adhesives find extensive application across diverse sectors. In the construction industry, they are integral for sealing window and door frames, curtain walls, and skylights, contributing to energy conservation by preventing air and water infiltration. For the automotive sector, window seal strip adhesive solutions are vital for bonding windshields, side windows, and trim, providing both structural integrity and noise reduction. Furthermore, these adhesives are increasingly used in marine environments for sealing portholes and hatches due to their resistance to saltwater and harsh weather, and in specialty applications such as HVAC systems and appliance manufacturing for critical sealing needs. Reputable window seal strip adhesive factory operations ensure that their products meet the rigorous demands of these varied environments.

Technical Advantages and Manufacturer Comparison

The technical advantages of advanced window seal strip adhesive solutions lie in their superior long-term performance, durability, and versatility. These include exceptional adhesion to a wide array of substrates without the need for primers, excellent elasticity to accommodate structural movements and thermal expansion, and robust resistance to UV radiation, extreme temperatures, and various chemicals. Many formulations also offer antifungal and antimicrobial properties, preventing mold growth in humid environments. The use of high-performance adhesives significantly reduces maintenance costs over the product's lifecycle by minimizing the need for re-application or repair.

When evaluating window seal strip adhesive suppliers, it's crucial to compare not just product specifications but also their manufacturing capabilities, certifications, and customer support. Leading window seal strip adhesive exporters often differentiate themselves through innovative R&D, offering custom formulations for specific project requirements, and providing comprehensive technical support. For instance, some companies specialize in high-tack formulations for rapid assembly lines, while others focus on long-term weatherability for high-rise buildings. A comprehensive comparison of typical adhesive types is provided below, highlighting key performance indicators that B2B decision-makers should consider.

Window Seal Strip Adhesive Type Comparison

| Adhesive Type | Key Advantage | Temperature Range (°C) | UV Resistance | Typical Application |

|---|---|---|---|---|

| Silicone | Excellent flexibility, UV stability, broad temp. range | -50 to +150 | Very High | Architectural glazing, curtain walls, high-performance windows |

| EPDM | Superior weather and ozone resistance, durability | -40 to +120 | High | Automotive seals, general construction weatherstripping |

| Butyl | Excellent moisture barrier, strong initial tack, air tightness | -30 to +80 | Moderate | Double glazing units, automotive body sealing, vapor barriers |

| Acrylic | Good adhesion to plastics, transparent options, moderate cost | -20 to +100 | Good | Plastic window profiles, interior applications, general assembly |

Custom Solutions and Real-World Application Cases

Recognizing that standard products may not always meet unique project specifications, many window seal strip adhesive companies offer bespoke or customized adhesive solutions. This involves tailoring adhesive properties such as viscosity, cure time, specific substrate compatibility, color, or even specific flame retardancy requirements. Through close collaboration with clients, R&D teams can develop formulations that precisely address the challenges of complex architectural designs or stringent automotive production lines. For example, a project involving large glass panels in a high-wind zone might require an adhesive with exceptional shear strength and elasticity to withstand dynamic loads, a requirement that standard off-the-shelf products might not fully satisfy.

A notable application case involves a major North American high-rise residential project that required an adhesive for its intricate window curtain wall system. The chosen window seal strip adhesive supplier developed a custom silicone formulation that not only met the extreme weatherproofing demands but also offered an extended open time for complex installation sequences, significantly reducing on-site labor costs and ensuring robust long-term performance. Another example is a leading European automotive manufacturer that partnered with a specialized adhesive window seal strip adhesive manufacturer to develop an adhesive with optimized acoustic dampening properties for luxury vehicle windshields, dramatically reducing cabin noise and enhancing passenger comfort. Such successful collaborations underscore the value of customized solutions and strong client-supplier partnerships in achieving superior project outcomes.

Ensuring Trustworthiness: FAQs, Delivery, and Support

Frequently Asked Questions (FAQs)

-

Q: What is the typical shelf life of window seal strip adhesive?

A: Shelf life varies by formulation, generally ranging from 6 to 18 months when stored in original, unopened container111s under recommended conditions (cool, dry place away from direct sunlight). -

Q: Can these adhesives be applied in cold weather?

A: While many adhesives have a broad service temperature range, application below 5°C (41°F) may affect cure time and initial tack. Specific low-temperature formulations are available from some window seal strip adhesive factories. -

Q: What types of substrates are compatible with your window seal strip adhesive quotes?

A: Our adhesives are engineered for compatibility with common window materials, including glass, anodized aluminum, vinyl (PVC), wood, and various coated metals. Always consult product datasheets for specific recommendations and perform adhesion tests.

Delivery and Warranty Commitments

Reliable delivery is paramount in B2B supply chains. Leading window seal strip adhesive suppliers typically offer competitive lead times, with standard orders processed within 3-7 business days for existing stock and customized solutions within 2-4 weeks, depending on complexity and order volume. Expedited shipping options are often available to meet urgent project deadlines. Manufacturers pride themselves on robust quality control systems, ensuring that every batch of adhesive meets specified performance parameters. Products are typically backed by a comprehensive warranty against manufacturing defects, ranging from 5 to 10 years, reflecting confidence in their long-term performance and durability. This commitment underscores the trustworthiness of established window seal strip adhesive exporters.

Customer Support and Technical Assistance

Exceptional customer support is a hallmark of reputable window seal strip adhesive companies. This includes dedicated technical support teams available to assist with product selection, application guidance, troubleshooting, and material compatibility testing. Many provide detailed technical datasheets (TDS) and safety data sheets (SDS) for all their window seal strip adhesive products, ensuring safe and effective use. Training programs for installation teams and on-site technical visits for large-scale projects are also commonly offered, fostering successful product integration and optimal performance. This holistic approach from inquiry to after-sales support builds lasting partnerships and reinforces client confidence.

Authoritative References and Further Reading

- ASTM International. (2023). ASTM Standards for Adhesives and Sealants. Retrieved from ASTM.org.

- European Committee for Standardization (CEN). (2022). EN Standards for Glazing and Sealants. Retrieved from CEN.eu.

- American Architectural Manufacturers Association (AAMA). (2021). AAMA Publications and Technical Information. Retrieved from AAMA.org.

- National Institute of Standards and Technology (NIST). (2020). Research in Building and Fire Safety. Retrieved from NIST.gov.

window seal strip adhesive companies, window seal strip adhesive company, window seal strip adhesive exporter, window seal strip adhesive exporters, window seal strip adhesive factories, window seal strip adhesive factory, window seal strip adhesive manufacturer, window seal strip adhesive products, window seal strip adhesive quotes, window seal strip adhesive suppliers.

-

LED Neon Rope Light Outdoor Companies: Durable & Bright Solutions

NewsAug.27,2025

-

Premium Window Seal Strip Adhesive: Manufacturers & Suppliers

NewsAug.26,2025

-

Best Window Seal Strip Adhesive Companies: Strong, Durable Seals

NewsAug.25,2025

-

Karcher A2004 Wet & Dry Vacuum Filter: Premium Replacement Cartridge

NewsAug.24,2025

-

Premium Vacuum Filter for Karcher VC 4, VC 6, VC 7 & Tineco A10, A11

NewsAug.23,2025

-

Hi-Flo HF155 Oil Filter KTM 250 EXC Racing 03-06 | OEM 580.38.005.000

NewsAug.22,2025